Aug . 21, 2025 19:20 Back to list

Premium Vinyl SPC Flooring: Waterproof, Durable, 8mm

The Rise of Rigid Core: An In-Depth Look at vinyl spc flooring in B2B Applications

In the rapidly evolving landscape of commercial and industrial infrastructure, the demand for durable, versatile, and aesthetically pleasing flooring solutions has never been higher. Among the myriad options, vinyl spc flooring, or Stone Plastic Composite flooring, has emerged as a frontrunner, particularly within the B2B sector. This revolutionary material, known for its exceptional rigidity and resilience, offers a compelling alternative to traditional flooring types, addressing critical concerns such as moisture resistance, longevity, and ease of maintenance. Its unique composition, primarily a blend of natural limestone powder and polyvinyl chloride, provides a robust core that stands up to heavy foot traffic, impacts, and fluctuating environmental conditions, making it an ideal choice for diverse high-demand environments from bustling retail spaces to critical healthcare facilities.

This comprehensive guide delves into the intricate details of vinyl spc flooring, exploring its cutting-edge manufacturing processes, key technical specifications, and broad applicability across various sectors. We will examine the market trends driving its adoption, compare its performance against other flooring materials, and highlight the strategic advantages it offers to businesses seeking long-term value and operational efficiency. Furthermore, we will shed light on the importance of selecting reputable manufacturers, understanding customization options, and reviewing real-world application cases to provide a holistic perspective for B2B decision-makers and technical procurement specialists.

Unpacking Industry Trends and Market Trajectories for SPC Flooring

The global flooring market is undergoing significant transformations, with sustainability, performance, and cost-effectiveness at the forefront of innovation. Vinyl spc flooring is perfectly positioned to capitalize on these trends. Current market analysis indicates a robust Compound Annual Growth Rate (CAGR) for the rigid core luxury vinyl tile (LVT) segment, largely driven by the increasing demand from commercial sectors, including hospitality, retail, healthcare, and education. This growth is fueled by SPC's ability to replicate the aesthetics of natural materials like wood and stone without their inherent vulnerabilities, such as susceptibility to moisture or wear.

A key trend observed is the rising preference for flooring solutions that offer quick installation and minimal disruption to operations, a characteristic where vinyl spc flooring excels due to its click-lock systems. Moreover, the emphasis on indoor air quality has led to a stricter regulatory environment, pushing manufacturers to produce flooring with low Volatile Organic Compound (VOC) emissions, a standard often met by high-quality SPC products. The increasing urbanization and commercial construction activities, particularly in emerging economies, are further propelling the market forward. Specialized segments, like vinyl gym flooring, are also seeing a surge as health and fitness facilities prioritize durable, impact-absorbing, and easy-to-clean surfaces. The overall trajectory points towards SPC flooring becoming a ubiquitous solution across nearly all commercial and institutional building types.

The Advanced Manufacturing Process of Rigid Core Vinyl SPC Flooring

The superior performance of vinyl spc flooring is a direct result of its sophisticated multi-layered structure and advanced manufacturing techniques. Unlike traditional pvc vinyl flooring or LVT, SPC's core is created through a specialized extrusion process that ensures unparalleled dimensional stability and rigidity. Understanding this process is crucial for appreciating the product's technical advantages.

Core Material Composition:

- SPC Core (Stone Plastic Composite Core): The heart of the product, typically composed of about 60-70% natural limestone powder, polyvinyl chloride (PVC) resin, and stabilizers. This blend is extruded at high temperatures to form a dense, homogeneous sheet.

- Wear Layer: A transparent, highly durable layer of pure PVC, often enhanced with UV coatings (e.g., Ceramic Bead, Diamond Coating) for superior scratch, stain, and wear resistance. This layer is critical for determining the product's longevity, particularly in commercial environments.

- Print Layer (Design Film): A high-definition decorative film that replicates the appearance of natural wood, stone, or abstract patterns. Advanced printing technologies ensure realistic textures and colors.

- Balance Layer/Underlayment: An optional but increasingly common layer, typically IXPE or EVA foam, adhered to the bottom. This layer provides sound absorption, cushioning, and helps to smooth out minor subfloor imperfections.

Manufacturing Process Flow:

- Raw Material Mixing: Precise quantities of limestone powder, PVC resin, plasticizers, and stabilizers are mixed thoroughly in large industrial mixers.

- Extrusion of SPC Core: The mixed material is fed into a twin-screw extruder, heated, and then extruded through a die to form a continuous, rigid SPC sheet. This process is distinct from the calendering method used for flexible vinyl, resulting in a much denser and more stable core.

- Four-Roll Calendaring & Lamination: The wear layer, print layer, and the extruded SPC core are fed into a multi-roll calendaring machine. Under precise heat and pressure, these layers are simultaneously pressed and laminated onto the SPC core, creating a seamless, integrated board.

- Annealing & Curing: The laminated sheets undergo a cooling and annealing process, where they are gradually brought to room temperature to relieve internal stresses and ensure maximum dimensional stability. This step is critical in preventing warping or expansion/contraction over time.

- Cutting & Profiling: The large sheets are cut into individual planks or tiles. High-precision CNC machinery is then used to mill the unique click-lock profiles (e.g., Unilin, Valinge) on the edges of each plank, enabling glue-less, floating installations.

- Quality Inspection & Packaging: Each batch undergoes rigorous quality control checks against international standards such as ISO 9001 for quality management, ASTM (American Society for Testing and Materials) and EN (European Norm) for performance characteristics like wear resistance, slip resistance, and dimensional stability. Products are then carefully packaged for distribution.

The meticulous control over each stage of this manufacturing process guarantees the consistent quality and superior performance of vinyl spc flooring, differentiating it significantly from other resilient flooring options.

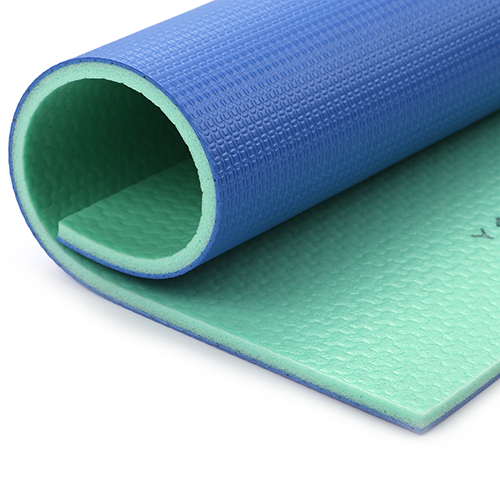

Figure 1: Illustration of the multi-layered structure of vinyl spc flooring.

Technical Parameters and Performance Metrics: A Comparative Analysis

For B2B buyers and technical specifiers, understanding the precise technical parameters of vinyl spc flooring is paramount. These metrics quantify performance, durability, and suitability for specific environments. Below is a comparative table highlighting key specifications of SPC flooring against other popular resilient flooring types.

Comparative Technical Specifications for Resilient Flooring Types

| Parameter | Vinyl SPC Flooring | LVT (Luxury Vinyl Tile/Plank) | WPC (Wood Plastic Composite) | Traditional PVC Vinyl Flooring (Sheet/Tile) |

|---|---|---|---|---|

| Core Composition | Stone Powder + PVC | Flexible PVC | Wood Powder + PVC | PVC |

| Total Thickness | 3.5mm - 8.0mm (e.g., 8mm vinyl flooring available) | 2.0mm - 5.0mm | 5.0mm - 8.0mm | 1.5mm - 3.0mm |

| Wear Layer Thickness | 0.3mm - 0.7mm (12 - 28 mil) | 0.1mm - 0.5mm (4 - 20 mil) | 0.3mm - 0.5mm (12 - 20 mil) | 0.1mm - 0.3mm (4 - 12 mil) |

| Dimensional Stability | Excellent (≤ 0.05% expansion/contraction) | Good (≤ 0.10% expansion/contraction) | Very Good (≤ 0.08% expansion/contraction) | Fair (≤ 0.25% expansion/contraction) |

| Waterproof Capability | 100% Waterproof (Core) | Water Resistant (Flexible Core) | Waterproof (Core) | Water Resistant (Surface) |

| Sound Insulation (IIC) | 50-60+ dB (with attached pad) | 30-40 dB (without pad) | 45-55+ dB (with attached pad) | 20-30 dB |

| Fire Rating | Bfl-s1 (European Standard, high) | Cfl-s1 | Cfl-s1 | Cfl-s1 |

| VOC Emissions | Very Low (FloorScore, GreenGuard Certified) | Low (FloorScore Certified) | Low (FloorScore Certified) | Varies (can be higher) |

| Installation Method | Click-Lock (Floating) | Glue-Down or Click-Lock | Click-Lock (Floating) | Glue-Down |

This table clearly illustrates the superior dimensional stability and waterproof capabilities of vinyl spc flooring, attributed to its rigid core. For projects requiring robust performance under varied conditions, such as high humidity or significant temperature fluctuations, SPC's minimal expansion and contraction make it the preferred choice. Furthermore, its excellent wear layer thickness options provide extended service life, reducing the total cost of ownership over time. The sound insulation properties are also a significant advantage, particularly for multi-story commercial buildings where noise reduction is critical.

Diverse Application Scenarios Across B2B Verticals

The inherent versatility and robust performance of vinyl spc flooring make it suitable for an expansive range of commercial, institutional, and light industrial applications. Its ability to combine aesthetic appeal with technical resilience addresses the specific demands of various sectors.

Key Application Environments:

- Retail & Commercial Spaces: High-traffic areas like supermarkets, boutiques, showrooms, and shopping malls benefit from SPC's durability and resistance to scuffs and indentations. Its wide range of designs also allows for the creation of inviting and brand-consistent environments.

- Healthcare Facilities: Hospitals, clinics, and assisted living centers require flooring that is hygienic, easy to clean, highly durable, and resistant to chemicals and stains. Vinyl spc flooring with appropriate wear layers and finishes meets stringent health and safety standards while providing a comfortable and quiet underfoot experience.

- Hospitality Sector: Hotels, restaurants, and resorts demand elegant yet robust flooring that can withstand constant use, spills, and heavy luggage. SPC offers luxurious aesthetics with the practical benefits of water resistance and low maintenance, ideal for lobbies, guest rooms, and dining areas.

- Educational Institutions: Schools, universities, and daycare centers need flooring that can endure heavy foot traffic, accidental spills, and provide acoustic comfort. SPC's durability, low VOC emissions, and ease of cleaning make it a healthy and practical choice for classrooms, hallways, and common areas.

- Office Buildings: Modern office environments prioritize comfort, acoustics, and aesthetics. Vinyl spc flooring offers excellent sound dampening properties, ergonomic comfort, and a professional appearance, suitable for open-plan offices, conference rooms, and private offices.

- Sports & Recreation Facilities: For areas requiring specific performance characteristics, such as dance studios, multi-purpose halls, or home gyms, specialized vinyl gym flooring solutions derived from SPC technology provide optimal shock absorption, traction, and durability. These products are engineered to support dynamic activities while minimizing impact on joints.

- Residential (Multi-Family & High-End): In apartment complexes and luxury homes, SPC flooring is chosen for its superior waterproof properties (e.g., in bathrooms, kitchens, basements), stability over radiant heating, and ability to resist wear from pets and children, offering a premium and worry-free living experience.

The adaptability of vinyl spc flooring to these diverse settings underscores its value proposition: a resilient, high-performance solution that delivers both functional superiority and design flexibility.

Unparalleled Technical Advantages of SPC Over Traditional Flooring

The technical advantages of vinyl spc flooring are multifaceted, stemming directly from its rigid core composition and advanced manufacturing. These benefits translate into significant operational and cost savings for B2B entities.

- Superior Dimensional Stability: Unlike WPC or traditional pvc vinyl flooring, SPC's limestone-PVC composite core is exceptionally stable. It exhibits minimal expansion or contraction under temperature fluctuations or humidity changes, preventing issues like warping, buckling, or gapping, which are common with wood or even some vinyl products. This makes it ideal for areas with direct sunlight exposure or fluctuating climates.

- 100% Waterproof: The non-porous nature of the SPC core makes it completely impervious to water. This renders it perfect for moisture-prone areas like bathrooms, kitchens, basements, laundries, and commercial spaces susceptible to spills or high humidity without the risk of swelling, rotting, or mold growth.

- Extreme Durability and Impact Resistance: The high density of the SPC core provides remarkable resistance to dents, scratches, and heavy impacts from falling objects or furniture. Its wear layer, typically thicker and more robust than other vinyl options, ensures longevity even in high-traffic commercial environments. This significantly reduces the need for frequent repairs or replacements.

- Easy and Rapid Installation: Most vinyl spc flooring comes with a precise click-lock system, allowing for floating installation without the need for adhesives. This dramatically reduces installation time and labor costs, minimizing downtime for businesses. It can often be installed directly over existing hard surfaces, eliminating costly subfloor preparation.

- Low Maintenance: SPC flooring is incredibly easy to clean and maintain. Its waterproof and stain-resistant surface only requires regular sweeping, vacuuming, and occasional damp mopping. This contributes to lower operational costs over the product's lifecycle compared to materials requiring specialized cleaning or sealing.

- Enhanced Acoustic Performance: Many SPC products feature an attached underlayment (IXPE or EVA foam), which provides excellent sound absorption properties. This significantly reduces impact noise and ambient sound transmission, creating quieter and more comfortable environments, particularly beneficial in multi-story buildings or open-plan offices.

- Cost-Effectiveness (Lifecycle Cost): While the initial purchase price might be slightly higher than some budget vinyl options, the long-term cost benefits of vinyl spc flooring are substantial. Its durability, low maintenance requirements, and extended lifespan translate into a lower total cost of ownership, making it a sound investment for B2B projects.

- Improved Indoor Air Quality: Reputable manufacturers produce vinyl spc flooring that is FloorScore® or GreenGuard certified, indicating very low VOC (Volatile Organic Compound) emissions. This ensures healthier indoor environments, critical for commercial spaces and contributing to LEED certification for green buildings.

These combined attributes position vinyl spc flooring as a high-performance, cost-effective, and sustainable choice for demanding commercial and institutional applications.

Strategic Partnerships: Manufacturer Comparison and Quality Assurance in SPC Flooring

When considering to buy vinyl flooring, especially vinyl spc flooring for large-scale projects, selecting the right manufacturer is as crucial as the product itself. The B2B landscape demands reliability, consistency, and a partnership approach. Key criteria for evaluating potential suppliers extend beyond just price, encompassing a holistic view of their capabilities and commitment to quality.

Key Factors for Manufacturer Selection:

- Certifications and Compliance: Verify the manufacturer's adherence to international quality and environmental standards. Look for ISO 9001 (Quality Management), ISO 14001 (Environmental Management), FloorScore® or GreenGuard (Low VOCs), CE marking (European conformity), and ASTM/EN compliance for specific performance metrics (e.g., slip resistance, fire rating, wear resistance). These certifications are non-negotiable indicators of a reputable supplier.

- R&D Capabilities and Innovation: A forward-thinking manufacturer invests in research and development to continuously improve product performance, introduce new designs, and optimize manufacturing processes. This includes innovations in wear layer technology (e.g., enhanced ceramic bead coatings), core formulations for even greater stability, and new design aesthetics.

- Production Capacity and Lead Times: For large B2B orders, a manufacturer's production capacity and ability to meet agreed-upon lead times are critical. Inquire about their manufacturing facilities, scalability, and logistical capabilities for timely global delivery.

- Customization Options: Evaluate their flexibility in offering custom solutions, including bespoke designs, specific wear layer thicknesses (e.g., for an 8mm vinyl flooring plank with a custom wear layer), or specialized surface treatments for anti-slip or anti-static properties.

- Quality Control Protocols: A transparent manufacturer will have stringent quality control procedures at every stage of production, from raw material inspection to finished product testing. Request documentation of their QC processes and performance test reports.

- Technical Support and After-Sales Service: Comprehensive technical support, including installation guidelines, maintenance recommendations, and responsive after-sales service, is vital. A strong partner will provide ongoing assistance and problem-solving capabilities.

- References and Case Studies: Ask for references from similar B2B projects or review their portfolio of successful application cases. This provides tangible evidence of their capabilities and reliability.

- Warranty and Longevity Commitment: A robust commercial warranty (often 10-25 years for SPC) signifies the manufacturer's confidence in their product's lifespan and performance under commercial conditions.

Partnering with a manufacturer that embodies these attributes ensures not only the delivery of high-quality vinyl spc flooring but also a seamless procurement process and long-term product satisfaction, directly impacting the success and longevity of your projects.

Figure 2: The aesthetic and functional appeal of vinyl spc flooring in a modern commercial space.

Custom Solutions and Tailored Offerings for Unique Project Demands

The B2B market for vinyl spc flooring is increasingly characterized by a demand for customized solutions that precisely match specific project aesthetics, performance requirements, and budgetary constraints. Leading manufacturers offer extensive customization capabilities, transforming standard products into bespoke flooring solutions.

Tailoring Your SPC Flooring Solution:

- Design and Aesthetic Customization: This is perhaps the most visible aspect of customization. Manufacturers can produce SPC planks or tiles with unique print layers, allowing for brand-specific colors, bespoke patterns, or highly realistic replications of rare wood species or natural stone. Custom textures, such as embossed-in-register (EIR) technology, can enhance realism.

- Performance-Driven Specifications: For projects with extreme demands, such as heavy industrial traffic or specialized healthcare environments, manufacturers can customize the wear layer thickness (e.g., from 0.5mm to 0.7mm or higher for extended durability), or integrate specific coatings for enhanced slip resistance (e.g., R10/R11 ratings) or anti-static properties.

- Thickness and Backing Options: While 8mm vinyl flooring is a common specification for robust applications, specific project needs might dictate varying total thicknesses. Furthermore, the inclusion and type of attached underlayment (IXPE, EVA, cork) can be customized to achieve desired acoustic performance or underfoot comfort levels.

- Size and Format Flexibility: Beyond standard plank and tile sizes, some manufacturers offer custom dimensions to fit unique architectural designs or to minimize waste in specific layouts. This includes extra-long planks or large format tiles.

- Integrated Solutions: For complex projects, suppliers can offer integrated solutions that include matching trims, transitions, and wall base products that perfectly complement the chosen vinyl spc flooring, ensuring a cohesive and professional finish throughout the facility.

Engaging early with the manufacturer's technical and design teams is key to leveraging these customization options effectively. A collaborative approach ensures that the final vinyl spc flooring solution is not just a product, but a strategic asset that enhances the facility's functionality, aesthetics, and long-term value, ultimately reflecting the client's brand identity and operational requirements.

Real-World Application Cases & Success Stories of Vinyl SPC Flooring

The theoretical advantages of vinyl spc flooring are best illustrated through its successful deployment in various demanding B2B environments. These application cases demonstrate the tangible benefits and return on investment for businesses.

Case Study 1: Large Retail Chain Renovation

- Challenge: A national retail chain sought to renovate over 50 of its high-traffic stores. Existing flooring (traditional tile and carpet) suffered from rapid wear, high maintenance costs, and frequent cracking due to heavy shelving and shopping cart traffic. Downtime for renovation needed to be minimized.

- Solution: Custom-designed vinyl spc flooring with a 0.7mm wear layer and a commercial-grade anti-scratch coating was chosen. Its click-lock system allowed for rapid installation directly over the existing hard floor in many locations, significantly reducing preparation time.

- Results: Installation time was reduced by 40% compared to traditional methods. The new SPC flooring proved highly resistant to foot traffic, point loads from displays, and spills. Maintenance costs decreased by 25% annually due to the ease of cleaning and reduced need for repairs. Customer feedback indicated a more modern and inviting store aesthetic, contributing to improved shopping experience.

Case Study 2: Hospital Wing Expansion

- Challenge: A major metropolitan hospital needed durable, hygienic, and quiet flooring for a new pediatric wing. The flooring had to withstand constant traffic from gurneys and wheelchairs, be easily sanitized, and contribute to a calm healing environment.

- Solution: A specialized anti-microbial vinyl spc flooring with an integrated acoustic backing was specified. The design replicated a soothing wood look, moving away from sterile traditional vinyl sheets. Its waterproof nature ensured no ingress of fluids.

- Results: The flooring provided exceptional sound dampening (reducing noise complaints by 30%), improving patient comfort. Its seamless installation and easy-to-disinfect surface met stringent infection control requirements. The durability stood up to heavy rolling loads, showing no signs of wear after two years of intensive use.

Case Study 3: University Sports Complex - Dedicated Vinyl Gym Flooring

- Challenge: A university required a high-performance, safe, and aesthetically pleasing surface for its multi-purpose gym and fitness areas, capable of absorbing impact from various sports activities while being easy to clean and maintain for thousands of students.

- Solution: A heavy-duty vinyl gym flooring variant of SPC, specifically engineered for sports applications, was installed. This product featured enhanced cushioning, superior shock absorption, and a slip-resistant textured surface, all while maintaining the rigid core benefits of waterproofness and dimensional stability.

- Results: The specialized vinyl gym flooring significantly improved safety and comfort for athletes, reducing strain and potential injuries. Its robust construction held up against weights, sports equipment, and high foot traffic. The vibrant, custom colors integrated seamlessly with the university's branding, enhancing the overall user experience and facility appeal.

These examples underscore that vinyl spc flooring is not merely a product but a strategic investment that delivers measurable improvements in operational efficiency, longevity, and user experience across diverse commercial and institutional sectors.

Ensuring Trust: FAQ, Delivery, Warranty & Customer Support

Building trust with B2B clients requires transparency, clear communication, and unwavering support throughout the entire project lifecycle, from initial inquiry to post-installation maintenance. Here, we address common questions and outline the commitment to service excellence for vinyl spc flooring solutions.

Frequently Asked Questions (FAQ) about Vinyl SPC Flooring:

Q1: What is the primary difference between vinyl spc flooring and traditional pvc vinyl flooring?

A1: The core composition is the main differentiator. Traditional pvc vinyl flooring (like LVT or sheet vinyl) typically has a flexible PVC core. Vinyl spc flooring features a rigid core made from a blend of natural limestone powder and PVC, which provides superior dimensional stability, greater dent resistance, and 100% waterproof properties due to its high density.

Q2: Is 8mm vinyl flooring a standard thickness for SPC, and why is it important?

A2: While not the only thickness, 8mm vinyl flooring is a premium and increasingly popular option for vinyl spc flooring, especially in commercial settings. The increased thickness contributes to enhanced durability, better impact resistance, and often allows for a thicker attached underlayment, improving acoustic performance and underfoot comfort. It generally signifies a higher-grade product designed for more demanding applications.

Q3: Can vinyl spc flooring be used for specialized applications like vinyl gym flooring?

A3: Yes, specifically engineered variants of vinyl spc flooring are excellent for gym and athletic applications. These products are often designed with enhanced wear layers, specialized textures for grip, and thicker integrated underlayments to provide superior shock absorption and impact resistance crucial for sports activities. When you buy vinyl flooring for a gym, look for products explicitly rated for athletic use.

Q4: How should vinyl spc flooring be maintained in a commercial environment?

A4: Maintenance for vinyl spc flooring is remarkably straightforward. Regular sweeping or vacuuming to remove loose dirt and debris is recommended. For deeper cleaning, a damp mop with a pH-neutral cleaner is typically sufficient. Avoid harsh chemicals, abrasive cleaners, or excessive water. For heavy-traffic areas, a periodic professional cleaning can refresh the appearance and extend the life of the floor. Ensure walk-off mats are used at entrances to minimize dirt transfer.

Q5: What is the typical lead time and delivery process when I buy vinyl flooring in bulk?

A5: Lead times for bulk orders of vinyl spc flooring can vary based on quantity, customization requirements, and current production schedules. Typically, standard products might ship within 2-4 weeks, while custom orders may take 6-10 weeks from order confirmation. Reputable manufacturers provide clear delivery schedules, offer global shipping logistics support, and ensure robust packaging to prevent damage during transit. It's advisable to communicate your project timeline early to facilitate efficient planning and delivery.

Delivery & Logistics Assurance:

We understand the critical importance of timely delivery for B2B projects. Our sophisticated logistics network ensures efficient and secure transportation of vinyl spc flooring globally. We provide transparent communication regarding order status, tracking information, and estimated arrival times. Our packaging is designed to protect products from damage during transit, ensuring your flooring arrives in perfect condition, ready for installation.

Comprehensive Quality Assurance & Warranty:

Our commitment to quality for vinyl spc flooring is absolute. Every batch undergoes rigorous multi-stage quality control checks, adhering to international standards (e.g., ISO, ASTM, EN). We back our products with comprehensive commercial warranties, typically ranging from 10 to 25 years, covering manufacturing defects and wear layer performance under normal commercial use. This warranty signifies our confidence in the longevity and durability of our flooring solutions, providing you with peace of mind and protecting your investment.

Dedicated Customer Support & Technical Expertise:

Beyond product delivery, our commitment extends to unparalleled customer support. Our dedicated technical team offers expert guidance on product selection, installation best practices, and maintenance protocols for vinyl spc flooring. We provide comprehensive after-sales service, addressing any queries or concerns promptly and effectively. Your satisfaction and the long-term success of your flooring project are our top priorities, fostering a reliable partnership for all your B2B flooring needs.

Conclusion: The Future-Proof Choice for B2B Flooring

Vinyl spc flooring has undeniably cemented its position as a transformative solution in the B2B flooring industry. Its unique rigid core construction delivers a confluence of critical benefits: unmatched dimensional stability, 100% waterproof capabilities, superior durability against heavy commercial traffic, and remarkably low maintenance requirements. These attributes address the most pressing challenges faced by facility managers, architects, and procurement professionals seeking long-lasting, cost-effective, and aesthetically versatile flooring solutions.

From bustling retail environments and demanding healthcare facilities to vibrant educational campuses and specialized vinyl gym flooring installations, SPC's adaptability and performance consistently exceed expectations. The emphasis on advanced manufacturing, stringent quality control, and adherence to international environmental and safety standards ensures that investing in vinyl spc flooring from reputable manufacturers is a strategic decision that promises a strong return on investment through extended lifespan, reduced operational costs, and enhanced indoor environments. As industries continue to evolve, the demand for resilient, high-performance materials will only grow, positioning vinyl spc flooring as a truly future-proof choice for B2B applications worldwide. For businesses looking to buy vinyl flooring that combines cutting-edge technology with practical advantages, SPC represents the pinnacle of modern flooring innovation.

References

- ASTM International Standards on Resilient Flooring.

- European Committee for Standardization (CEN) - EN Standards for Resilient Floor Coverings.

- ISO 9001:2015 Quality Management Systems – Requirements.

- Resilient Floor Covering Institute (RFCI) – FloorScore® Certification Program Documentation.

- GreenGuard Environmental Institute – GreenGuard Certification Standards for Building Materials.

- Journal of Vinyl and Additive Technology – Peer-reviewed articles on polymer science and applications.

- National Institute of Building Sciences (NIBS) – Whole Building Design Guide (WBDG) on Flooring Systems.

- ResearchGate – Academic studies on material science and composite development.

- MarketsandMarkets – Global Flooring Market Forecasts and Analysis.

- Grand View Research – SPC Flooring Market Analysis Reports.

-

Durable Volleyball Ground Mats for Safe & Competitive Play

NewsNov.24,2025

-

Premium Volleyball Court Mat: Safety, Durability & Performance for Global Play

NewsNov.23,2025

-

Durable and Eco-Friendly Rubber Play Mats Outdoor for Safer Playgrounds

NewsNov.22,2025

-

Comprehensive Guide to Types of Interlock Tiles: Materials, Uses & Trends

NewsNov.22,2025

-

Exploring Different Types of Interlocking Tiles: Global Uses and Benefits

NewsNov.21,2025

-

PVC Interlocking Floor Tiles Price – Comprehensive Guide for Smart Flooring Choices

NewsNov.20,2025