Sep . 13, 2025 08:40 Back to list

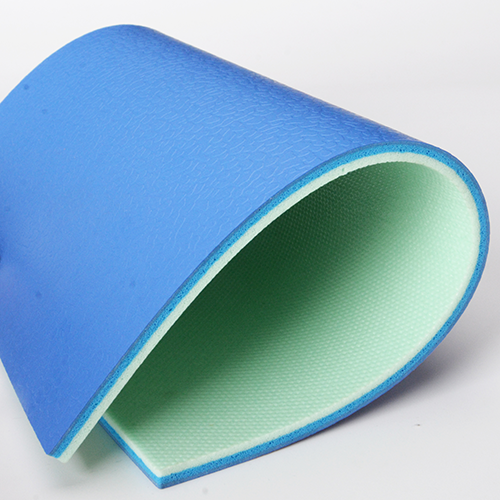

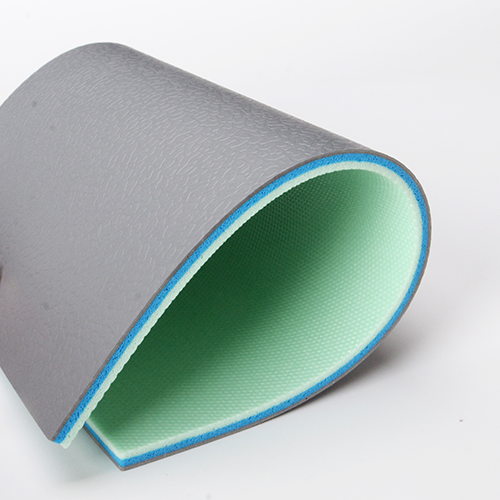

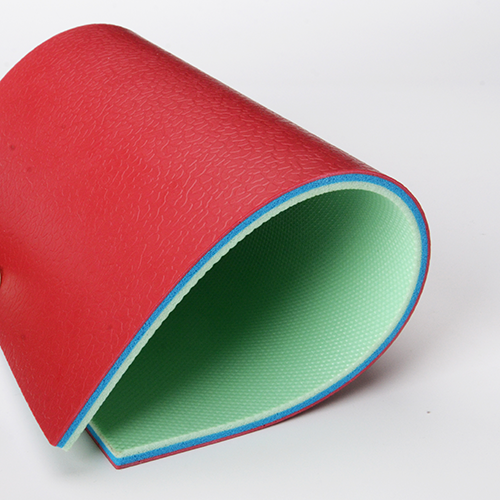

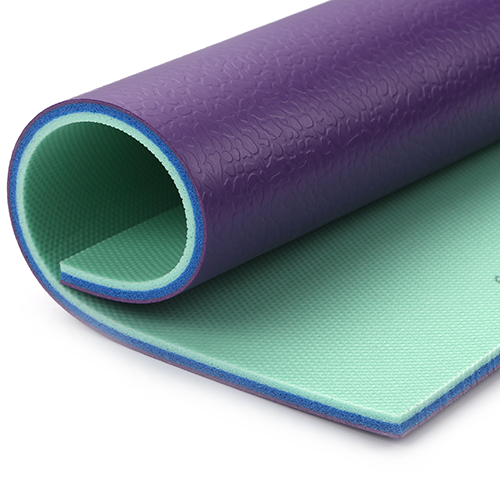

Durable Vinyl Gym Mat | Non-Slip & Protective Gym Flooring

Introduction to High-Performance Sports Flooring Solutions

In the rapidly evolving landscape of sports and fitness infrastructure, the choice of flooring is paramount, directly influencing athlete safety, performance, and facility longevity. Advanced flooring materials are crucial for creating optimal environments, from professional sports arenas to community fitness centers. Among these, high-performance PVC solutions, exemplified by the vinyl gym mat, stand out for their engineered resilience and versatility. This document delves into the technical aspects, manufacturing precision, and diverse applications of modern sports flooring, specifically focusing on solutions designed for demanding athletic environments.

We will explore the intricacies of multi-layer PVC sports flooring, detailing its construction, performance benefits, and how it addresses the critical needs of contemporary sports facilities. Our analysis will encompass industry trends, technical specifications, and real-world application case studies, providing a comprehensive guide for B2B decision-makers and technical procurement specialists.

Current Industry Trends in Sports Flooring Technology

The sports flooring market is experiencing significant growth driven by increasing participation in sports, stringent safety regulations, and a demand for sustainable, high-performance materials. Key trends include the integration of advanced polymers, enhanced shock absorption properties, and modular design for ease of installation and maintenance. Innovations in PVC flooring, such as those found in high-grade vinyl gym mat systems, are at the forefront of this evolution.

- Sustainable Materials: Manufacturers are increasingly utilizing recycled content and developing PVC formulations with lower VOC emissions to meet environmental standards and consumer demand for green building solutions.

- Enhanced Performance Characteristics: Focus on improved force reduction, energy return, and anti-slip coefficients to maximize athlete safety and optimize performance across various sports.

- Design Versatility: The adoption of digital printing technologies allows for a wider range of aesthetics, including realistic wood grains (e.g., similar to wpc vinyl flooring) and custom branding, without compromising functional integrity.

- Durability and Longevity: Development of wear layers with superior abrasion resistance, extending the service life of flooring in high-traffic sports environments.

- Modular and Interlocking Systems: Growth in systems resembling vinyl floor tiles or even vinyl spc flooring, offering flexible installation, easy replacement, and adaptability for multi-purpose venues, contrasting with traditional vinyl floor carpet which offers different aesthetic and functional profiles.

These trends underscore a commitment to engineering solutions that are not only high-performing but also economically viable and environmentally responsible, ensuring sports facilities are equipped for future demands.

Manufacturing Process of Multi-Layer PVC Sports Flooring

The production of high-quality PVC sports flooring, such as a advanced vinyl gym mat, involves a sophisticated multi-stage process designed to engineer optimal performance and durability. This technical process ensures the final product meets stringent international standards for sports surfaces.

1. Raw Material Blending

High-grade PVC resin is precisely blended with plasticizers, stabilizers, pigments, and fillers. This compound formulation is critical for achieving the desired flexibility, color, UV resistance, and overall mechanical properties of the flooring. Adherence to ISO 9001 material selection protocols ensures consistency.

2. Calendering and Layer Formation

The PVC compound is then fed into calenders, large rollers that flatten and spread the material into thin, uniform sheets. This process forms the core layers: the durable backing, the fiberglass reinforcement layer (for dimensional stability), and the compact/foam underlayment. Precise temperature and pressure control are vital at this stage.

3. Printing and Design Application

The decorative design layer, often mimicking wood, stone, or vibrant solid colors, is applied using advanced rotogravure printing technology. This ensures high-resolution aesthetics and consistent pattern registration across large production runs.

4. Wear Layer and Surface Treatment

A transparent, highly durable PVC wear layer is applied over the printed design. This layer is crucial for abrasion resistance and protection against heavy foot traffic. A final 'gem surface' embossing, followed by a UV-cured treatment, enhances anti-slip properties and provides a stain-resistant, easy-to-clean finish.

5. Lamination and Curing

All distinct layers are precisely aligned and laminated under controlled heat and pressure to form a single, cohesive multi-layer structure. The material then undergoes a curing and cooling phase to stabilize its dimensions and molecular structure, preventing warping or shrinkage post-installation.

6. Precision Cutting and Quality Assurance

The finished flooring material is precisely cut into rolls or tiles according to specified dimensions. Throughout the entire process, continuous in-line quality control checks monitor parameters such as thickness, dimensional stability (EN 434), indentation resistance (EN 433), color fastness (EN ISO 105-B02), and slip resistance (DIN 51130). Products must meet or exceed relevant standards like EN 14904 (sports surfaces) and ISO 10582.

This meticulous process ensures that each unit of sports flooring delivers consistent, high-level performance, offering superior energy absorption, controlled friction, and exceptional durability, contributing to reduced impact injuries and an extended service life in demanding environments.

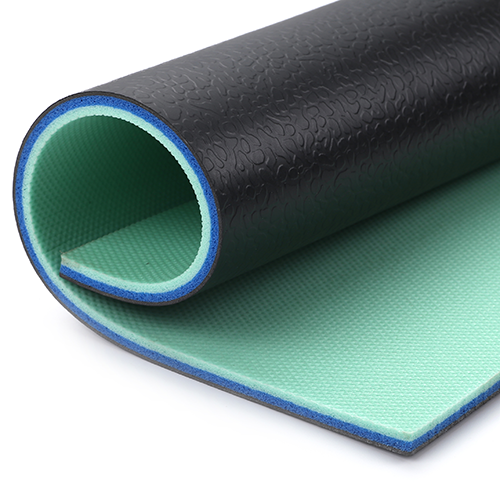

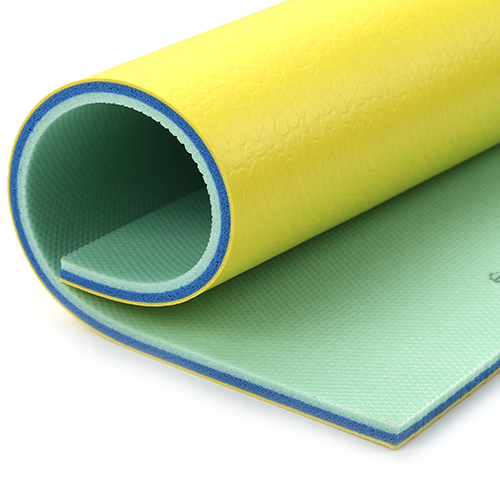

Technical Specifications: Multi-layer PVC Sports Flooring with Gem Surface 6.0

The multi-layer PVC Sports Flooring with gem surface 6.0 is engineered for peak performance in athletic facilities. Its construction provides a balance of resilience, shock absorption, and stability, critical for athlete safety and comfort. Below are the detailed specifications for this advanced vinyl gym mat solution:

| Parameter | Specification (Gem Surface 6.0) | Testing Standard |

|---|---|---|

| Total Thickness | 6.0 mm ± 0.2 mm | EN 428 |

| Wear Layer Thickness | 1.5 mm (min) | EN 429 |

| Total Weight | 4.5 kg/sqm ± 0.2 kg/sqm | EN 430 |

| Width per Roll | 1.5 m | Manufacturer Spec |

| Length per Roll | 20 m | Manufacturer Spec |

| Force Reduction (Shock Absorption) | >25% (Type P1, P2) | EN 14904 |

| Vertical Deformation | ≤2.0 mm | EN 14904 |

| Ball Rebound | >90% | EN 14904 |

| Slip Resistance (Friction) | 0.5 - 0.7 (μ) | EN 13036-4 / DIN 51130 |

| Abrasion Resistance | Group T (very high) | EN 660-2 |

| Residual Indentation | ≤0.1 mm | EN 433 |

| Dimensional Stability | ≤0.4% | EN 434 |

| Fire Resistance | Bfl-s1 (European Class) | EN 13501-1 |

| Service Life Expectancy | 10-15 years (under normal use) | Industry Standard |

These specifications underscore the product's suitability for high-intensity sports and fitness applications, providing a safe, durable, and high-performance surface. The "gem surface" design specifically contributes to enhanced grip and aesthetic appeal, differentiating it from standard PVC flooring.

Diverse Application Scenarios

The versatility and robust performance of the multi-layer PVC sports flooring with gem surface 6.0 make it an ideal choice for a broad spectrum of athletic and recreational facilities. Its engineered characteristics cater to the specific demands of various sports and user groups.

- Gymnasiums and Fitness Centers: Perfect for weight training areas, aerobic studios, and group exercise rooms, providing essential shock absorption and impact sound reduction.

- Multi-Sport Halls: Suitable for badminton, volleyball, basketball, and handball courts, where consistent ball bounce, controlled slip resistance, and athlete comfort are paramount.

- Educational Institutions: From school gyms to university sports complexes, offering a durable, safe, and low-maintenance surface for daily physical education and competitive events.

- Rehabilitation Centers: The cushioned surface aids in recovery and reduces joint stress for patients undergoing physical therapy and rehabilitation exercises.

- Dance Studios and Martial Arts Arenas: Provides the necessary friction and impact protection for rigorous movements and intricate footwork, superior to basic vinyl floor carpet options.

- Commercial Sports Venues: For professional training facilities and community sports complexes, ensuring a high-performance surface that meets international competition standards.

Target industries include not only sports and education but also the burgeoning corporate wellness sector, where dedicated fitness spaces benefit from specialized flooring like a robust vinyl gym mat to promote employee health and activity.

Technical Advantages of Advanced PVC Sports Flooring

The technical design of multi-layer PVC sports flooring offers a multitude of advantages that directly translate into operational benefits for facility managers and enhanced experiences for users.

- Superior Shock Absorption: The multi-layer structure, particularly the foam backing, provides exceptional force reduction, significantly reducing impact on joints and muscles, thereby minimizing sports-related injuries. This is a critical factor for any professional vinyl gym mat.

- Optimal Slip Resistance: The specialized gem surface texture, combined with a UV-cured treatment, ensures consistent grip, preventing slips and falls during dynamic movements without impeding agility.

- Exceptional Durability and Wear Resistance: Engineered with a robust wear layer, this flooring withstands heavy foot traffic, abrasive sports equipment, and intensive cleaning regimes, ensuring a long service life of 10-15 years, far surpassing conventional materials.

- Dimensional Stability: Reinforced with fiberglass, the flooring exhibits excellent dimensional stability, resisting expansion, contraction, and curling due to temperature and humidity fluctuations, common issues with less advanced vinyl floor tiles.

- Hygienic and Easy Maintenance: The non-porous surface prevents bacterial growth and is resistant to stains, sweat, and disinfectants, making cleaning and sanitization straightforward and cost-effective.

- Acoustic Comfort: The cushioned layers contribute to significant sound absorption, reducing ambient noise levels from impacts and movement, creating a more pleasant environment for athletes and spectators.

- Cost-Effectiveness: While the initial investment is for a premium product, the extended service life, minimal maintenance requirements, and reduced potential for injury-related liability contribute to a lower total cost of ownership over time.

These advantages collectively position this multi-layer PVC sports flooring as a superior choice for facilities prioritizing performance, safety, and long-term operational efficiency.

Vendor Comparison: Advanced Sports Flooring Solutions

Selecting the right sports flooring vendor is a critical decision for facility owners and operators. While many options exist, discerning the differences in product quality, technical support, and overall value is essential. Below is a comparative analysis focusing on key differentiators among leading sports flooring solutions, including specialized vinyl gym mat providers.

| Feature/Product Type | Multi-layer PVC (Gem Surface 6.0) | Homogeneous PVC (Typical) | Wood Sports Flooring (Maple) | Rubber Gym Matting |

|---|---|---|---|---|

| Construction | Multi-layer with fiberglass, foam backing, wear layer, gem surface. | Single layer, uniform composition throughout. | Solid wood strips, often on a subfloor system. | Recycled or virgin rubber granules, vulcanized. |

| Shock Absorption (EN 14904) | >25% (Excellent, Type P1/P2) | 15-20% (Good) | 22-50% (Variable, System Dependent) | 10-25% (Good for heavy impact) |

| Slip Resistance | Optimal (0.5-0.7 μ), consistent wet/dry. | Good (0.4-0.6 μ), can vary with wear. | Good (0.4-0.6 μ), requires specific finishes. | Very High (0.6-0.8 μ), can be sticky. |

| Durability/Wear | Very High (Group T), 10-15 years. | High, 8-12 years. | High, 20+ years with regular refinishing. | High, 5-10 years (heavy-duty). |

| Maintenance | Low, easy to clean, no waxing required. | Moderate, occasional waxing may be needed. | High, regular sanding and refinishing. | Low, simple cleaning. |

| Water Resistance | Excellent, impervious. | Excellent, impervious. | Poor, susceptible to moisture damage. | Good, but seams can be vulnerable. |

| Installation | Glue-down or loose-lay (for specific types). | Glue-down. | Complex, professional installation. | Loose-lay or glue-down. |

This comparison highlights the superior balance of performance, durability, and ease of maintenance offered by multi-layer PVC sports flooring, making it a compelling choice over traditional options like wood or more basic PVC variations for modern sports facilities.

Customized Solutions for Unique Facility Requirements

Understanding that every sports facility has distinct operational and aesthetic requirements, manufacturers of advanced PVC sports flooring offer extensive customization options. This flexibility ensures that the chosen vinyl gym mat solution perfectly aligns with specific brand guidelines, performance demands, and architectural visions.

- Color and Design Palette: Beyond standard offerings, custom colors can be matched to corporate identities or school colors. Digital printing technologies allow for complex patterns, logos, and court line markings to be integrated directly into the flooring design, providing a seamless and professional finish.

- Thickness and Performance Tuning: While 6.0 mm is a robust standard, facilities with highly specific impact absorption needs (e.g., professional basketball courts vs. general fitness areas) can opt for tailored thicknesses to fine-tune force reduction and energy return characteristics.

- Surface Textures: While the gem surface offers excellent general performance, alternative textures can be developed for niche applications requiring very specific coefficients of friction, whether higher or lower.

- Acoustic Properties: For multi-purpose halls or facilities located within mixed-use buildings, customized backing layers can be engineered to further enhance sound insulation, mitigating noise transfer to adjacent areas.

- Roll vs. Tile Format: While typically supplied in rolls for seamless installation over large areas, custom cuts or tile formats (similar to specialized vinyl floor tiles) can be provided for modular systems, ease of replacement, or smaller, irregularly shaped spaces.

Engaging with expert technical teams allows for a collaborative design process, ensuring that the customized flooring solution not only meets but exceeds functional and aesthetic expectations, delivering a truly bespoke athletic environment.

Application Case Studies & Customer Experience

Real-world implementations demonstrate the tangible benefits of deploying high-quality multi-layer PVC sports flooring. These case studies highlight successful integration and positive customer feedback, reinforcing the product's effectiveness.

Case Study 1: University Recreation Center Upgrade

Client: Major State University, USA

Challenge: The university's main gymnasium, used for intercollegiate basketball, volleyball, and campus recreation, suffered from outdated, high-maintenance flooring that offered insufficient shock absorption, leading to increased athlete complaints regarding joint pain.

Solution: Installation of 3,500 square meters of multi-layer PVC Sports Flooring with gem surface 6.0 in custom colors to match university branding. The project included bespoke court line markings integrated during manufacturing.

Results: Athlete feedback consistently reported a significant reduction in impact fatigue and improved comfort. The facility manager noted a 40% reduction in weekly cleaning time compared to the previous surface. The flooring's Bfl-s1 fire resistance rating also enhanced compliance with safety regulations.

Case Study 2: Private Fitness Chain Expansion

Client: "Elite Fitness" – A national chain of premium health clubs

Challenge: Elite Fitness required a flooring solution for 15 new studio locations that could withstand high-intensity interval training (HIIT), provide excellent grip for yoga and Pilates, and offer acoustic dampening to minimize noise disturbance between studios.

Solution: Custom-specified vinyl gym mat with enhanced acoustic backing, utilizing the multi-layer PVC Sports Flooring with gem surface 6.0. The uniform aesthetic across all locations was achieved through a consistent color scheme.

Results: The flooring successfully absorbed impact from high-energy workouts and reduced sound transmission by an average of 18dB, as verified by post-installation acoustic testing. Customer satisfaction surveys highlighted the comfort and visual appeal of the new studios, leading to increased membership retention.

These examples illustrate the adaptability and reliable performance of our multi-layer PVC flooring, consistently delivering on expectations for safety, durability, and user experience.

Quality Assurance and Authoritative Certifications

Our commitment to excellence is underpinned by rigorous quality assurance processes and adherence to international certification standards. This provides our clients with verifiable proof of product performance, safety, and environmental responsibility, reinforcing our position as an authoritative provider of sports flooring solutions.

- ISO 9001:2015 Certification: Our manufacturing facilities operate under a certified Quality Management System, ensuring consistent product quality, process efficiency, and continuous improvement.

- ISO 14001:2015 Certification: Demonstrates our commitment to environmental responsibility, covering sustainable manufacturing practices and waste management.

- EN 14904 Compliance: Our sports flooring solutions, including the vinyl gym mat with gem surface 6.0, meet the stringent requirements for multi-sport indoor surfaces as specified by EN 14904, certifying performance in areas like shock absorption, vertical deformation, and ball bounce.

- CE Marking: Products conform to European health, safety, and environmental protection standards.

- Fire Resistance Ratings: Achieves Bfl-s1 classification (EN 13501-1), signifying very limited contribution to fire and very low smoke production, crucial for public safety.

- Formaldehyde Emission Standards: Products comply with E1 class standards, ensuring very low formaldehyde emissions and contributing to healthy indoor air quality.

These certifications are not merely badges but represent a foundational assurance of quality, safety, and reliability, providing our clients with peace of mind and demonstrating our unwavering commitment to authoritative industry standards.

Trustworthiness: FAQ, Logistics, Warranty & Support

Building long-term partnerships is founded on transparency and reliable support. This section addresses common inquiries, logistical considerations, and our unwavering commitment to post-sales service, ensuring full trustworthiness in our offerings of products like the advanced vinyl gym mat.

Frequently Asked Questions (FAQ)

Q1: What is the recommended subfloor preparation for multi-layer PVC sports flooring?

A1: A clean, dry, smooth, and level subfloor (e.g., concrete, plywood) is essential. Any irregularities can telegraph through the flooring. Moisture content must be within acceptable limits (typically

Q2: How does the "gem surface" enhance performance?

A2: The gem surface provides a unique micro-texture that optimizes the coefficient of friction, ensuring consistent grip for athletes during rapid movements, while also contributing to enhanced visual appeal and ease of cleaning.

Q3: Is the flooring suitable for outdoor use?

A3: While highly durable, this specific multi-layer PVC sports flooring is designed for indoor sports applications. Prolonged exposure to direct UV radiation and extreme weather conditions is not recommended for this product variant.

Lead Time & Fulfillment Details

Standard lead time for multi-layer PVC Sports Flooring with gem surface 6.0 is typically 4-6 weeks from order confirmation, depending on order volume and customization requirements. Expedited production and shipping options are available upon request and can be discussed with your dedicated account manager. We maintain efficient logistics partnerships to ensure timely and secure global delivery.

Warranty Commitments

We stand behind the quality of our products. Multi-layer PVC Sports Flooring with gem surface 6.0 comes with a comprehensive 8-year limited warranty against manufacturing defects and excessive wear under normal use conditions, providing long-term assurance for your investment.

Customer Support Information

Our dedicated technical support team is available to assist with pre-sales consultations, installation guidance, and post-sales inquiries. For technical specifications, project planning, or general assistance, please contact us via our website, email, or telephone. We are committed to providing prompt and expert support to ensure optimal product performance and customer satisfaction.

Conclusion

The multi-layer PVC Sports Flooring with gem surface 6.0 represents the zenith of modern sports flooring technology. By integrating advanced material science with precision manufacturing, this vinyl gym mat solution delivers unparalleled safety, performance, durability, and aesthetic appeal. Its technical advantages, ranging from superior shock absorption and optimal slip resistance to ease of maintenance and long service life, address the critical needs of contemporary sports facilities across various sectors. With robust certifications and a commitment to customer trust, it stands as a premium investment for any organization seeking to provide a world-class athletic environment.

References

- European Standard EN 14904: Surfaces for sports areas - Indoor surfaces for multi-sports use - Specification.

- International Organization for Standardization (ISO) 9001: Quality management systems – Requirements.

- DIN 51130: Testing of floor coverings; determination of the anti-slip properties; walking method; ramp test.

- European Standard EN 13501-1: Fire classification of construction products and building elements – Part 1: Classification using data from reaction to fire tests.

- ASTM F2772: Standard Specification for Indoor Performance Resilient Sports Flooring.

-

Durable Volleyball Ground Mats for Safe & Competitive Play

NewsNov.24,2025

-

Premium Volleyball Court Mat: Safety, Durability & Performance for Global Play

NewsNov.23,2025

-

Durable and Eco-Friendly Rubber Play Mats Outdoor for Safer Playgrounds

NewsNov.22,2025

-

Comprehensive Guide to Types of Interlock Tiles: Materials, Uses & Trends

NewsNov.22,2025

-

Exploring Different Types of Interlocking Tiles: Global Uses and Benefits

NewsNov.21,2025

-

PVC Interlocking Floor Tiles Price – Comprehensive Guide for Smart Flooring Choices

NewsNov.20,2025