Aug . 30, 2025 02:20 Back to list

Net of Badminton Court & Multi-Sport Court Tiles | Durable

The Core of Play: Understanding the net of badminton court

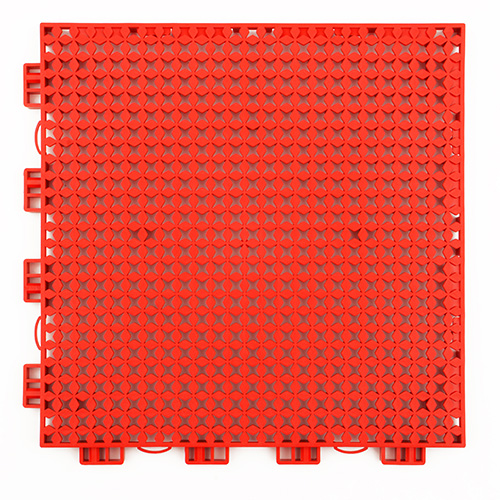

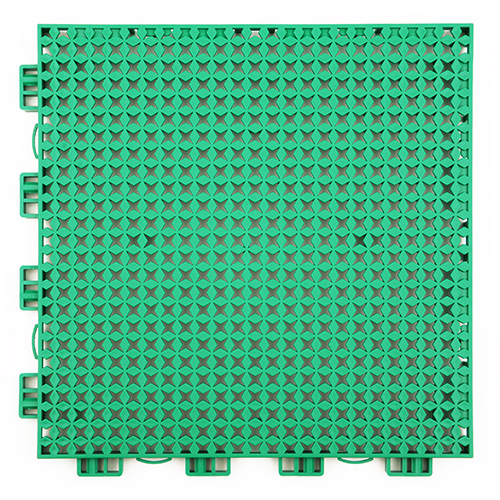

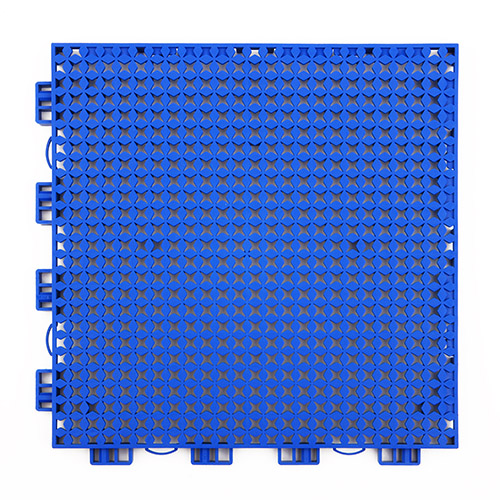

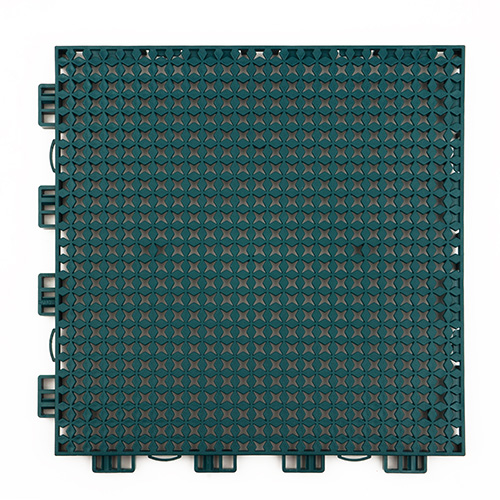

In the realm of professional and recreational badminton, the integrity and performance of the net of badminton court are paramount. This seemingly simple component dictates the flow of play, ensures fairness, and contributes significantly to the overall player experience. Beyond its functional role, the net assembly—comprising the net itself, posts, and tensioning mechanisms—is a critical piece of sports infrastructure that demands precision engineering, robust materials, and adherence to international standards. As B2B decision-makers and facility managers increasingly prioritize durable, high-performance solutions, understanding the technical specifications, manufacturing processes, and application considerations of these systems becomes essential. This article delves into the intricate details of modern badminton net systems, providing insights into their construction, advantages, and integration within diverse sports environments, including those utilizing advanced sport court floor tiles and multi sport court tiles.

The demand for versatile sports facilities has also elevated the importance of selecting the right court components, whether for indoor sport court tiles or outdoor sport court tiles. A high-quality badminton net system is engineered to withstand rigorous use, diverse environmental conditions, and maintain optimal performance over extended periods, reflecting a smart investment in any sports venue.

Industry Trends and Market Dynamics

The global sports infrastructure market is experiencing robust growth, driven by increasing participation in sports, government investments in public facilities, and a rising awareness of health and fitness. Badminton, as one of the world's most popular racket sports, commands a significant share of this growth. Key trends influencing the development and procurement of the net of badminton court include:

- Durability and Longevity: Operators seek materials that offer extended service life, reducing replacement costs and maintenance downtime. This translates to an increased demand for high-tenacity polymers and corrosion-resistant metals for net posts.

- Sustainability: A growing emphasis on environmentally friendly manufacturing processes and recyclable materials is influencing procurement decisions. Suppliers demonstrating eco-conscious practices gain a competitive edge.

- Multi-Sport Versatility: Facilities are increasingly designed for multi-sport use. The demand for easily deployable and stowable badminton net systems that integrate seamlessly with various sport court floor tiles and multi sport court tiles is on the rise.

- Technological Integration: While not as prevalent as in other sports, there's nascent interest in "smart" court elements, potentially involving integrated sensors for net tension or performance analysis, though traditional systems remain dominant.

- Compliance with BWF Standards: Adherence to the Badminton World Federation (BWF) regulations for net height, mesh size, and post stability is non-negotiable for competitive play, driving innovation in adjustable and certified systems.

These trends underscore the need for manufacturers to provide high-quality, technically advanced solutions that meet the evolving demands of both indoor sport court tiles and outdoor sport court tiles installations.

Manufacturing Process of a High-Performance net of badminton court

The production of a robust net of badminton court system is a multi-stage process, demanding precision from material selection to final assembly and testing. Below is a detailed overview:

Step 1: Material Selection & Extrusion

Net Material: High-tenacity synthetic fibers such as Nylon 6, Polyethylene (PE), or Polyester (PET) are selected for their excellent tensile strength, abrasion resistance, and low moisture absorption. For outdoor applications, UV-stabilized grades are mandatory. These polymers are extruded into monofilaments or multifilament yarns.

Post Material: High-grade steel (e.g., galvanized steel or stainless steel for corrosion resistance, particularly in coastal or high-humidity environments) or reinforced aluminum alloys are chosen for net posts due to their strength-to-weight ratio and rigidity. Bases often incorporate cast iron or heavy-gauge steel for stability.

Step 2: Net Fabrication (Braiding/Knitting)

The chosen yarns are then processed into net webbing. Common methods include:

- Knotless Netting: Often preferred for its smooth finish and uniform strength distribution, created by interweaving strands without knots, reducing potential failure points.

- Knotted Netting: Traditional method where individual strands are tied at each intersection, providing robust structure.

Mesh size is precisely controlled to BWF standards (15-20mm square mesh). The top band, typically a double-layered white canvas or vinyl, is sewn onto the net, often incorporating a wire rope or cord for tensioning.

Step 3: Post Manufacturing & Finishing

Net posts undergo processes like CNC machining for precise cutting and drilling, welding for structural integrity, and then finishing. For steel posts, galvanization or powder coating (often in blue or green for aesthetics and added protection) is applied to prevent corrosion. Aluminum posts may be anodized. Integrated tensioning mechanisms (winches, pulley systems) are assembled and calibrated.

Target Industries: While not typical for heavy industries like petrochemical or metallurgy, the manufacturing principles of precision, material science, and corrosion resistance are directly transferable. For sports facilities, the focus is on robust performance and longevity in varied environments (e.g., high humidity in indoor courts, UV exposure in outdoor settings).

Step 4: Quality Control & Testing Standards

Every component undergoes stringent quality control. Key tests include:

- Tensile Strength Testing: Netting and cables are tested to ensure they meet specified breaking points (e.g., ASTM D2256).

- UV Resistance Testing: For outdoor nets, accelerated weathering tests (e.g., ISO 4892) confirm long-term UV stability.

- Net Height & Tension Consistency: Ensuring the net can be set to the precise 1.55m at posts and 1.524m at the center (BWF Rule 1.2).

- Post Stability & Load Bearing: Posts are tested for stability under net tension and external forces (e.g., ANSI/BIFMA X5.1 for structural integrity).

Manufacturers often adhere to ISO 9001 for quality management and BWF equipment standards for sports performance.

Service Life: A professionally manufactured net of badminton court, when properly maintained, can have a service life of 5-10 years for recreational use and 3-5 years for high-intensity competitive use, depending on environmental factors and material specifications. For high-end solutions, materials like UHMWPE (Ultra-High Molecular Weight Polyethylene) can extend this considerably.

Technical Specifications and Parameters

Understanding the precise technical parameters of a net of badminton court is crucial for ensuring compliance, performance, and player safety. Here’s a summary of typical specifications:

| Parameter | Specification (BWF Compliance) | Typical Range (High-Performance) |

|---|---|---|

| Net Length | 6.10 meters (20 ft) | 6.02 - 6.10 meters |

| Net Depth | 760 mm (30 inches) | 760 - 800 mm |

| Mesh Size | Square, 15-20 mm | 18 mm (optimal) |

| Net Material | Dark-colored, fine cord (Nylon, PE, PET) | High-tenacity Nylon 6.6 or UV-stabilized PE |

| Cord Diameter | Min. 0.8 mm (no specified max) | 1.0 mm - 2.5 mm |

| Top Band Width | 75 mm (3 inches), folded over cord/wire | 75 mm - 100 mm (white) |

| Net Post Height | 1.55 meters (5 ft 1 inch) from floor | 1.55 meters (adjustable options) |

| Net Height (Center) | 1.524 meters (5 ft 0 inches) from floor | Precisely 1.524 meters |

| Post Material | Rigid, sturdy material | Galvanized Steel, Stainless Steel, Anodized Aluminum |

| Post Base Type | Fixed sockets or portable weighted bases | Heavy-duty cast iron, rubber-padded for floor protection |

These specifications are crucial not only for competition but also for ensuring a consistent and enjoyable experience in recreational settings, minimizing issues related to improper net height or inadequate tension. The choice of materials for the net and posts significantly impacts these parameters, particularly in terms of durability and weather resistance for outdoor sport court tiles.

Application Scenarios

The versatility of a well-designed net of badminton court system allows for its deployment across a broad spectrum of facilities:

- Professional Sports Arenas & Training Centers: Requiring BWF-certified systems with fixed or professional-grade portable posts, high-tensile nets, and precise tensioning for elite competition and training. These often integrate with specialized indoor sport court tiles designed for high-impact sports.

- Educational Institutions (Schools & Universities): Demand for durable, easy-to-set-up, and safe systems for physical education classes and intramural sports. Portable or semi-permanent systems are common, adaptable for multi-sport gymnasiums featuring versatile sport court floor tiles.

- Community Sports Halls & Recreation Centers: High-traffic environments needing robust, low-maintenance options that can be quickly installed and removed. These facilities often utilize multi sport court tiles for maximum utility.

- Outdoor Multi-Sport Complexes & Parks: Crucial requirement for weather-resistant, UV-stabilized nets and corrosion-protected posts. Permanent or heavy-duty portable systems are vital, installed on outdoor sport court tiles capable of withstanding various weather conditions.

- Private & Residential Courts: Focus on convenience, aesthetics, and durability for personal enjoyment. Solutions range from basic portable nets to custom-installed permanent systems.

In all these scenarios, the compatibility of the net system with the underlying court surface, whether it's specialized sport court floor tiles or generic outdoor paving, is a key consideration to prevent damage and ensure optimal play.

Technical Advantages of Advanced Badminton Net Systems

Investing in a high-quality net of badminton court provides several distinct technical and operational advantages:

- Superior Durability & Longevity: Engineered from high-tensile, UV-stabilized polymers (for nets) and corrosion-resistant metals (for posts), these systems resist wear and tear, fading, and environmental degradation, significantly extending service life and reducing total cost of ownership.

- Consistent Net Tension: Precision-engineered tensioning mechanisms (e.g., crank winches, internal spring-loaded systems) ensure consistent net height and tautness across the entire width, crucial for fair play and BWF compliance. This prevents sagging in the center, a common issue with lower-grade nets.

- Enhanced Safety: Stable, well-anchored posts minimize wobble and the risk of collapse. Smooth net materials reduce potential for snags or injuries. Integrated base padding for portable units protects multi sport court tiles from scratches and impacts.

- Ease of Installation & Portability: Many advanced systems feature quick-assembly designs, allowing for rapid setup and takedown. Portable options with integrated wheels or balanced weights facilitate effortless movement without damaging indoor sport court tiles.

- Weather Resistance (for Outdoor Applications): Specialized outdoor net of badminton court systems incorporate marine-grade hardware, galvanized or stainless steel posts, and UV-treated nets to withstand extreme temperatures, moisture, and intense sunlight, making them ideal for outdoor sport court tiles.

- Compliance & Professionalism: BWF-certified systems guarantee adherence to international playing standards, vital for competitive venues and enhancing the professional image of any sports facility.

These advantages translate into better player experience, reduced operational costs, and greater versatility for facilities managing various types of sport court floor tiles.

Vendor Comparison: Key Differentiators

Selecting the right vendor for your badminton net system is crucial. Beyond basic specifications, several factors differentiate top-tier providers. Here’s a comparative overview:

| Feature/Criterion | Premium Vendor (Example) | Standard Vendor (Example) | Budget Vendor (Example) |

|---|---|---|---|

| Net Material & Construction | UV-stabilized High-Tenacity Nylon 6.6, Knotless, 2.0-2.5mm cord. BWF Approved. | PE or Standard Nylon, Knotted, 1.0-1.5mm cord. Meets BWF. | Basic PE, thin cord, often knotted. Minimal UV. |

| Post Material & Finish | Heavy-gauge Galvanized Steel or Anodized Aluminum. Electrostatic Powder Coated. Marine-grade hardware. | Painted Steel or Standard Aluminum. Basic finish. | Light-gauge Painted Steel. Prone to rust. |

| Tensioning System | Precision Worm Gear Winch with internal locking mechanism. Fine adjustment. | Standard Lever Winch or Simple Pulley. Adequate tension. | Rope & Cleat or basic hook. Difficult to maintain precise tension. |

| Base/Mounting Options | Integrated weighted bases (100kg+ per post) with non-marking wheels, or precision floor sockets. | Standard weighted bases (50-70kg), or basic floor sleeves. | Lightweight bases (sub 30kg) or simple anchors. Less stable. |

| Certifications & Compliance | BWF Approved, ISO 9001, ASTM F1557. | Meets BWF guidelines, internal QC. | No specific certifications. |

| Warranty & Support | 5-10 years on manufacturing defects, comprehensive after-sales. | 1-3 years limited warranty. | 6 months - 1 year, often parts-only. |

| Customization | Extensive options: branding, custom colors, specialized materials. | Limited branding or color choices. | None. |

Customized Solutions for Every Court

Recognizing that no two sports facilities are identical, leading manufacturers offer bespoke solutions for the net of badminton court. Customization options extend beyond standard dimensions and include:

- Branding Integration: Facility logos or sponsor branding can be incorporated into the top band of the net or on the net posts, enhancing visibility and professional appearance.

- Material Specialization: For extreme environments (e.g., highly saline coastal areas or intense UV zones), specialized materials like UHMWPE netting or 316-grade stainless steel posts can be specified for superior corrosion and abrasion resistance.

- Color Matching: Net posts can be powder-coated in specific RAL colors to match existing facility aesthetics or branding guidelines.

- Unique Tensioning Mechanisms: Custom winch designs or counterweight systems for specific architectural or operational needs, ensuring optimal net tension and ease of adjustment for multi-sport courts.

- Integrated Storage Solutions: For portable systems, custom-designed trollies or storage cases that protect components and simplify transportation and storage, particularly important for facilities with limited space or those frequently reconfiguring sport court floor tiles.

These customized approaches ensure that the badminton net system is not just functional but also a seamlessly integrated, aesthetically pleasing, and highly durable asset for the facility.

Application Case Studies

Case Study 1: Grand City Sports Complex – Multi-Sport Versatility

Client: Grand City Sports Complex, a premier urban facility offering a range of sports including basketball, volleyball, and badminton.

Challenge: The complex required a versatile badminton net system that could be quickly deployed on its existing multi sport court tiles without causing damage and easily stored when not in use. High traffic demanded extreme durability and compliance with competitive standards.

Solution: We provided a series of BWF-certified portable badminton net systems featuring heavy-duty, rubber-padded bases with integrated locking wheels and precision crank winches. The nets were constructed from 2.0mm UV-stabilized Nylon, ensuring longevity and consistent tension. The posts were anodized aluminum for lightweight strength and corrosion resistance.

Outcome: The complex experienced a 70% reduction in setup/takedown time compared to previous systems, allowing for more efficient court utilization. The durability ensured minimal maintenance over three years of intensive use, maintaining a professional playing experience and protecting the underlying sport court floor tiles.

Case Study 2: Coastal Community Park – Extreme Weather Endurance

Client: "Sunshine Coast" Community Park, an outdoor recreational facility located in a high-salinity, high-UV coastal environment.

Challenge: Previous badminton net installations rapidly degraded due to salt spray corrosion on posts and UV damage to nets, requiring frequent and costly replacements. A permanent, weather-proof solution was needed for outdoor sport court tiles.

Solution: We engineered a custom solution utilizing 316-grade stainless steel posts with flush-mount ground sleeves, ensuring maximum corrosion resistance. The net of badminton court was fabricated from UHMWPE fiber with additional UV inhibitors, capable of withstanding prolonged sun exposure and salt-laden air. All hardware was marine-grade.

Outcome: After five years, the net system showed virtually no signs of corrosion or material degradation, significantly surpassing the lifespan of previous installations (typically 1-2 years). This provided a durable, low-maintenance playing solution that enhanced the park's outdoor amenities.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Frequently Asked Questions (FAQ)

- Q: What is the standard height for a badminton net?

A: According to BWF rules, the net should be 1.55 meters (5 ft 1 inch) high at the posts and 1.524 meters (5 ft 0 inches) high at the center of the court. - Q: How do I choose between portable and fixed net posts?

A: Portable posts are ideal for multi-purpose halls or temporary setups on sport court floor tiles, offering flexibility. Fixed posts are recommended for dedicated badminton courts, providing maximum stability and durability. Your facility's design and usage frequency will dictate the best choice. - Q: What maintenance does a badminton net system require?

A: Regular inspection for wear and tear, especially on the net and tensioning cables, is recommended. For outdoor systems, periodic cleaning and re-lubrication of moving parts (winches) are essential. Store nets indoors when not in extended use to prolong life, particularly on outdoor sport court tiles. - Q: Are your products BWF certified?

A: Many of our high-performance badminton net systems are BWF approved or compliant, meaning they meet the strict technical requirements for international competition. Specific product certifications are available upon request.

Lead Time & Fulfillment

Standard badminton net systems typically have a lead time of 2-4 weeks from order confirmation to shipment. Customized solutions or large-volume orders may require 6-8 weeks, depending on complexity and current production schedules. We maintain a robust supply chain to ensure timely delivery for both indoor sport court tiles and outdoor sport court tiles projects globally.

Warranty Commitments

Our badminton net systems are backed by a comprehensive warranty, reflecting our confidence in their quality and durability. Standard warranties typically range from 5 to 10 years on manufacturing defects for net posts and 1-3 years for net webbing under normal use. Specific terms and conditions are provided with each quotation.

Customer Support & After-Sales Service

We are committed to providing exceptional customer support throughout the lifecycle of your product. Our technical support team is available to assist with installation queries, maintenance advice, and troubleshooting. Spare parts for all our badminton net systems are readily available, ensuring maximum uptime for your facilities. We also offer detailed installation guides and video tutorials for ease of setup.

Conclusion

The net of badminton court is far more than a simple barrier; it is a precisely engineered component critical to the sport's integrity and enjoyment. From advanced material science in netting and posts to sophisticated tensioning mechanisms and rigorous testing protocols, every aspect of its design and manufacturing contributes to a superior playing experience. For B2B stakeholders in sports facility management, education, or community development, understanding these nuances is key to making informed procurement decisions. Opting for high-performance, BWF-compliant, and durable systems ensures not only player satisfaction and safety but also a sustainable, cost-effective investment that complements any modern sports court, whether utilizing advanced sport court floor tiles, multi sport court tiles, indoor sport court tiles, or outdoor sport court tiles. By prioritizing quality, customization, and reliable vendor support, facilities can elevate their badminton offerings and secure their reputation as premier sports destinations.

References

- Badminton World Federation (BWF) Statutes & Regulations. Official BWF Website.

- ASTM International Standards for Sports Equipment and Facility Surfacing. ASTM.org.

- International Organization for Standardization (ISO) 9001: Quality Management Systems. ISO.org.

- "Advanced Polymer Composites in Sports Equipment." Journal of Sports Engineering and Technology.

- "Corrosion Resistance of Steel and Aluminum Alloys in Outdoor Sporting Environments." Materials Science & Engineering Journal.

-

Durable Volleyball Ground Mats for Safe & Competitive Play

NewsNov.24,2025

-

Premium Volleyball Court Mat: Safety, Durability & Performance for Global Play

NewsNov.23,2025

-

Durable and Eco-Friendly Rubber Play Mats Outdoor for Safer Playgrounds

NewsNov.22,2025

-

Comprehensive Guide to Types of Interlock Tiles: Materials, Uses & Trends

NewsNov.22,2025

-

Exploring Different Types of Interlocking Tiles: Global Uses and Benefits

NewsNov.21,2025

-

PVC Interlocking Floor Tiles Price – Comprehensive Guide for Smart Flooring Choices

NewsNov.20,2025