Sep . 19, 2025 15:40 Back to list

Outdoor Sport Court Tiles: Durable, Safe & High Performance

The Evolution and Demand for Advanced outdoor sport court tiles

The global demand for high-performance sports infrastructure is experiencing a significant surge, driven by increasing participation in recreational and competitive sports. Within this landscape, outdoor sport court tiles have emerged as a premier solution, offering unparalleled durability, safety, and versatility compared to traditional surfacing options. This comprehensive overview explores the technical intricacies, application benefits, and strategic considerations for selecting advanced modular sports surfaces for B2B stakeholders, including facility managers, urban planners, and sports federations.

Industry Trends Driving Innovation in Sport Surfacing

- Sustainable Materials: A growing emphasis on eco-friendly solutions has led to the development of tiles utilizing recycled content and materials with lower environmental impact, aligning with LEED certification requirements for green building.

- Enhanced Player Safety: Innovations in shock absorption and anti-slip surface technology are paramount, aiming to reduce injuries and extend player careers. This includes advanced cushioning systems designed to mitigate impact forces on joints and muscles.

- Multi-Sport Functionality: Facilities increasingly require surfaces that can adapt to various sports, from basketball and tennis to pickleball and volleyball, optimizing space utilization and reducing investment costs. Modular designs inherently support this flexibility.

- Durability and Low Maintenance: The need for surfaces that withstand extreme weather conditions, heavy usage, and require minimal upkeep is a key driver, especially for public and institutional facilities seeking to lower operational expenditures over the long term.

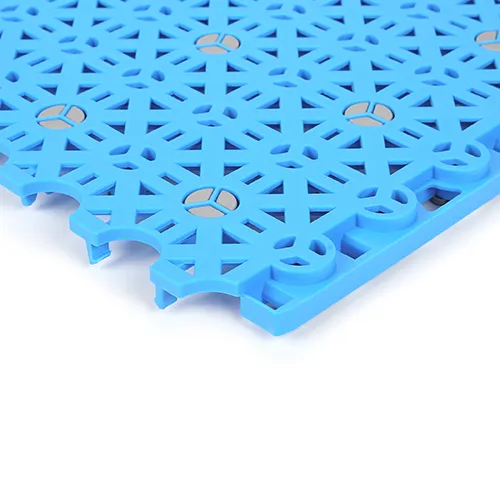

- Rapid Installation & Portability: Modular outdoor sport court tiles offer significant advantages in installation speed, allowing for quicker project completion and minimizing disruption. The ability to dismantle and relocate courts also supports temporary event setups.

These trends underscore a market shift towards intelligent, engineered solutions that prioritize performance, sustainability, and economic viability. Products like our SES cushion tiles-E620 basketball court tiles exemplify these advancements, providing a robust and player-friendly surface for diverse applications.

Technical Specifications and Performance of outdoor sport court tiles

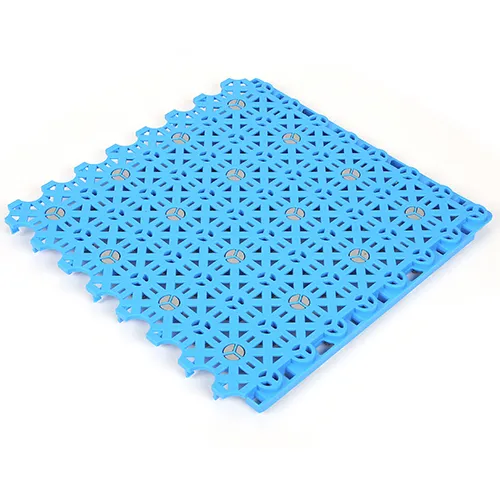

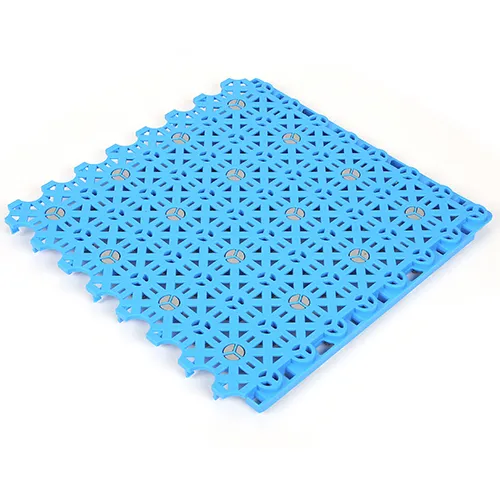

The superior performance of outdoor sport court tiles is rooted in their advanced material science and engineering design. Typically fabricated from high-grade virgin polypropylene (PP) enriched with UV stabilizers and anti-aging agents, these tiles are built to withstand the rigors of intense play and environmental exposure. Key technical parameters define their suitability for specific sports and operational environments.

Key Parameters for High-Performance Sport Surfaces

- Shock Absorption (Force Reduction): Measured by standards like ASTM F2772, this parameter quantifies the surface's ability to absorb kinetic energy upon impact, reducing stress on athletes' joints. High-quality tiles offer 15-30% force reduction.

- Ball Rebound: Critical for sports like basketball and tennis, this measures how consistently and accurately a ball bounces off the surface, typically expressed as a percentage of the ball's drop height. Values often range from 90-98%.

- Coefficient of Friction (Anti-Slip): Essential for preventing slips and falls, this measures the grip between footwear and the surface. Standards like DIN 51130 specify minimum requirements for athletic surfaces.

- Dimensional Stability: The ability of the tile to maintain its shape and interlocking integrity across wide temperature fluctuations, crucial for preventing warping or gapping in outdoor settings.

- Vertical Deformation: How much the surface deflects under load, influencing player comfort and energy return. Controlled deformation is vital for preventing excessive fatigue.

Product Specification Table: SES Cushion Tiles-E620 Basketball Court Tiles

| Parameter | Measurement/Standard | Value (SES Cushion Tiles-E620) |

|---|---|---|

| Tile Material | High-grade Virgin Polypropylene (PP) with UV Stabilizers | Premium PP, 100% Recyclable |

| Tile Dimensions | Length x Width x Height | 250mm x 250mm x 13mm (approx. 9.84" x 9.84" x 0.51") |

| Shock Absorption (I.S.%) | ASTM F2772-11 | 25% - 28% |

| Ball Rebound (B.R.%) | ASTM F2772-11 | 95% - 98% |

| Coefficient of Friction (μ) | DIN 51130 | ≥ 0.65 (Dry), ≥ 0.60 (Wet) |

| Load Bearing Capacity (Static) | kN/m² | ≥ 160 kN/m² |

| Temperature Range | Operational Tolerance | -30°C to +60°C |

| Warranty Period | Manufacturer's Warranty | 10 Years (Limited) |

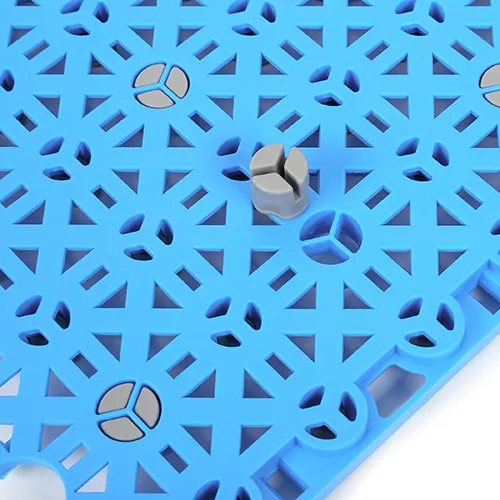

The advanced grid structure and precisely engineered interlocking system of these tiles ensure excellent water drainage, preventing standing water and maintaining playability even after heavy rainfall. The inherent properties of polypropylene, coupled with specialized additives, grant these tiles exceptional resistance to UV degradation, chemical exposure, and fungal growth, contributing to their extended service life.

Precision Engineering: The Manufacturing Process of outdoor sport court tiles

The production of high-performance outdoor sport court tiles involves a meticulously controlled process designed to ensure durability, player safety, and consistent performance. This multi-stage manufacturing sequence leverages advanced polymer science and precision molding techniques to create a resilient and functional product.

Key Stages of Production:

-

Material Selection & Preparation:

High-grade virgin polypropylene (PP) granules are selected for their excellent mechanical properties, chemical resistance, and weatherability. Crucially, UV stabilizers and anti-aging agents are compounded into the raw material to ensure long-term color retention and structural integrity when exposed to sunlight and varying temperatures. Pigments are added for specific court colors. All raw materials undergo stringent quality checks against ISO standards for purity and consistency.

-

Injection Molding:

The prepared PP compound is fed into high-precision injection molding machines. Here, it is heated to a molten state and injected under high pressure into meticulously crafted steel molds. The design of these molds is critical, forming the intricate interlocking mechanisms, the textured playing surface for optimal grip, and the underlying structural reinforcement elements (e.g., pillars, ribs) that provide cushioning and stability. This process ensures dimensional accuracy and uniformity across all tiles.

-

Cooling & Demolding:

Once injected, the molten plastic is rapidly cooled within the mold to solidify into the final tile shape, preventing deformation. Automated robotic systems then carefully demold the finished tiles, minimizing human contact and ensuring consistency in finish and form.

-

Quality Control & Testing:

Every batch of tiles undergoes rigorous quality assurance, adhering to international testing standards. This includes visual inspections for cosmetic defects, dimensional checks using precision calipers and laser scanners, and performance testing. Key tests involve:

- ASTM F2772 (Shock Absorption, Ball Rebound, Surface Effect, Vertical Deformation)

- EN 14877 (Synthetic Surfaces for Outdoor Sports Areas – Requirements)

- Anti-slip Coefficient (e.g., DIN 51130, R9-R13 ratings)

- UV Resistance (accelerated weathering tests like ISO 4892-2)

- Load Bearing Capacity (static and dynamic tests to simulate heavy equipment and player movement)

- Color Fastness (ISO 105-B02 to ensure long-term color stability)

Tiles that do not meet these stringent international and proprietary standards are recycled, ensuring only top-tier products reach the market, contributing to a high standard of sport court tiles for sale.

-

Packaging & Distribution:

Approved tiles are then stacked, securely packaged to prevent damage during transit, and prepared for shipment. Efficient logistics ensure timely delivery to installation sites globally.

This comprehensive process ensures that each modular tile delivers superior performance, longevity, and safety across diverse applications. The focus on high-quality virgin polypropylene and advanced molding techniques contributes significantly to their extended service life, often exceeding 15 years, and their exceptional resistance to environmental degradation, a critical factor for any outdoor sport court tiles installation.

Versatile Applications: Deploying outdoor sport court tiles Across Diverse Environments

The adaptability and robust performance characteristics of outdoor sport court tiles make them ideal for a broad spectrum of athletic and recreational installations. Their modular design facilitates rapid deployment and minimal disruption, catering to both permanent and temporary venues.

Key Application Environments:

- Basketball Courts: Essential for professional training facilities, municipal parks, schools, and private residences, providing consistent ball rebound, excellent traction, and critical shock absorption, as exemplified by the SES cushion tiles-E620 basketball court tiles.

- Tennis Courts: Offering a true and even playing surface with optimal speed of play, minimal glare, and low maintenance, making them ideal outdoor tennis court tiles for clubs and residential use.

- Pickleball Courts: The rapidly growing sport of pickleball benefits immensely from the precise bounce and anti-slip properties offered by modular pickleball sport court tiles, providing a safer and more enjoyable playing experience.

- Multi-Sport Game Courts: Perfect for schools, municipal parks, and residential complexes requiring a single, versatile surface capable of hosting various sports like volleyball, badminton, futsal, and roller hockey.

- Event & Temporary Installations: Their interlocking nature allows for quick setup and dismantle, making them ideal for sports events, tournaments, and pop-up courts where speed and flexibility are paramount.

Technical Advantages in Typical Application Scenarios:

- Enhanced Player Safety: Superior shock absorption, typically between 15-30% force reduction, significantly reduces impact on athletes' joints and ligaments. The textured, non-slip surface minimizes fall risks, even in wet conditions, due to engineered drainage.

- Exceptional Durability & Weather Resistance: Engineered with high-grade UV stabilizers and robust polymers, these tiles withstand extreme temperatures (-30°C to +60°C), heavy rainfall, snow, and intense sunlight without fading, cracking, or warping. This translates to a significantly longer service life (10-15+ years) compared to traditional surfaces like asphalt or acrylic.

- Superior Drainage & Rapid Drying: The perforated or elevated grid design allows water to flow through and underneath the playing surface, preventing puddles and enabling courts to dry rapidly after rain, thereby extending playtime and reducing slip hazards.

- Low Maintenance Requirements: Unlike conventional courts that demand periodic resurfacing, crack repairs, and specialized cleaning, modular tiles simply require occasional cleaning. The open grid prevents debris accumulation on the playing surface.

- Rapid Installation & Cost-Effectiveness: The interlocking tile system dramatically cuts down on installation time and labor costs, making them a more economical choice over the lifecycle of the court. Minimal sub-base preparation is often sufficient, further reducing initial investment.

Technical Advantages and Strategic Vendor Selection for outdoor sport court tiles

Choosing the right outdoor sport court tiles is a critical decision that impacts long-term investment and user satisfaction. Leading manufacturers distinguish themselves through superior technical design, rigorous testing, and comprehensive support. Our SES cushion tiles-E620 basketball court tiles, for instance, are engineered to deliver unparalleled performance and longevity, supported by numerous international certifications, establishing a benchmark for quality sport court tiles for sale.

Certifications and Compliance: A Mark of Authoritativeness

Authoritative certifications validate product quality, safety, and performance, providing peace of mind for B2B purchasers. Key certifications include:

- ISO 9001:2015: Demonstrates a robust quality management system across design, development, production, installation, and service, ensuring consistent product quality.

- FIBA (International Basketball Federation): Many top-tier tiles, including the SES-E620 series, meet or exceed FIBA standards for basketball surfaces, ensuring professional-grade playability, ball rebound, and safety.

- CE Certification: Indicates compliance with European health, safety, and environmental protection standards, crucial for market access in the EU.

- RoHS & REACH Compliance: Ensures products are free from hazardous substances, underscoring environmental responsibility and safety for both users and installers.

- ASTM F2772: Standard Specification for Indoor and Outdoor Court Surfaces for Multiple Sports, affirming performance characteristics like shock absorption, ball rebound, and surface effect.

- ITF (International Tennis Federation) or USAPA (USA Pickleball Association): Relevant for specific outdoor tennis court tiles or pickleball sport court tiles, confirming adherence to sport-specific playing characteristics.

Comparative Analysis: Modular Tiles vs. Traditional Surfaces

A strategic comparison highlights the distinct advantages of modular outdoor sport court tiles against conventional acrylic or asphalt surfaces, particularly for long-term operational efficiency and player experience.

| Feature | Modular Sport Tiles (e.g., SES Cushion Tiles) | Traditional Acrylic/Asphalt |

|---|---|---|

| Installation Speed | Very Fast (1-3 days for a standard court, minimal curing time) | Slow (1-2 weeks, weather dependent, extensive curing) |

| Maintenance | Minimal (occasional cleaning, easy individual tile replacement) | High (resurfacing every 5-8 years, crack repair, extensive cleaning) |

| Player Safety (Impact) | Excellent shock absorption (25-30% force reduction, cushioning layer) | Moderate (harder surface, lower shock absorption, higher injury risk) |

| Water Drainage | Superior (perforated design allows rapid through-flow, quick drying) | Dependent on slope, puddles can form, slower drying time |

| UV & Weather Resistance | Excellent (UV stabilizers, extreme temperature resilient, fade-resistant) | Good (fading, cracking, and surface degradation over time) |

| Service Life | 10-15+ years (often with comprehensive warranty) | 8-12 years (with regular, costly resurfacing and maintenance) |

| Customization | High (wide range of colors, integrated court lines, logos, multi-sport layouts) | Moderate (painted after installation, limited color options, prone to fading) |

The data clearly illustrates the superior long-term value, operational benefits, and enhanced player experience offered by modern outdoor sport court tiles, particularly those designed for high performance like our SES Cushion Tiles. This robust construction ensures consistent playability and reduced operational expenditure over its extensive service life, making them a prudent choice for discerning buyers.

Tailored Solutions and Proven Performance: Case Studies for outdoor sport court tiles

Understanding that each project has unique requirements, leading providers of outdoor sport court tiles offer extensive customization options. This flexibility ensures that courts align perfectly with specific aesthetic, functional, and budgetary parameters, from vibrant color schemes to integrated branding and multi-sport layouts. This modularity extends to specialized tile designs optimized for basketball sport court tiles, outdoor tennis court tiles, or pickleball sport court tiles.

Customization Capabilities: Precision for Every Project

- Extensive Color Palettes: A wide array of UV-stable colors allowing for vibrant designs, team colors, or aesthetic integration with surrounding architecture and branding.

- Integrated Court Markings & Logos: Precision-cut lines and embedded logos or decals for professional aesthetics and clear demarcation of play areas, eliminating the need for periodic repainting.

- Multi-Sport Configurations: Design flexibility to create courts that can seamlessly transition between different sports, maximizing utility for schools, community centers, and recreational facilities.

- Edge Ramps & Accessories: Custom solutions for safe transitions off the court, including wheelchair access ramps, along with integrated portable goals, nets, and fencing.

- Specialized Tile Types: Offering varied tile designs (e.g., specific cushion layers, surface textures, material densities) optimized for the unique demands of different sports, such as high-impact basketball sport court tiles or speed-focused outdoor tennis court tiles.

Application Case Studies: Delivering Excellence Globally

Our products, including the renowned SES cushion tiles-E620 basketball court tiles, have been deployed in thousands of installations worldwide, serving a diverse clientele from professional sports organizations to educational institutions and private residences. These case studies underscore our commitment to quality and client satisfaction, solidifying our reputation for sport court tiles for sale that truly perform.

Case Study 1: Municipal Sports Complex Revitalization

Client: City of Springfield Parks & Recreation Department

Challenge: Replace aging, cracked asphalt courts with a durable, multi-sport surface that could withstand heavy public use and diverse weather conditions, while prioritizing player safety and low maintenance for their community.

Solution: Installation of 1,500 sq meters of premium outdoor sport court tiles, specifically tailored for basketball, pickleball, and volleyball. The chosen tiles featured advanced cushioning for impact absorption (27% I.S.) and an integrated drainage system. Custom color combinations were used to match the city's branding and enhance aesthetic appeal.

Outcome: The project was completed in just 4 days, significantly ahead of traditional resurfacing timelines, minimizing public inconvenience. The new courts have received overwhelmingly positive feedback from residents for their comfort, safety, and vibrant appearance. Annual maintenance costs have been reduced by an estimated 60%, and court availability has increased due to rapid drying after rainfall, enhancing community engagement.

Case Study 2: Private School Athletic Facility Upgrade

Client: Elite Academy (K-12 Private School)

Challenge: Upgrade an outdoor basketball court to meet collegiate training standards, ensuring maximum player protection during intense training sessions and long-term durability against constant use by students of all ages. Speed of installation was crucial to minimize disruption to the academic calendar.

Solution: Implementation of SES cushion tiles-E620 basketball court tiles, renowned for their superior shock absorption (over 25% I.S.) and excellent ball rebound (97%). The school's official logo was seamlessly incorporated into the court design using pre-fabricated custom tiles. The modular system allowed for installation within a single weekend during a short academic break, ensuring zero disruption.

Outcome: The school now boasts a state-of-the-art basketball court that is both safer and performs at a professional level. Student athletes and coaches reported significantly less fatigue and joint stress, directly impacting training quality. The durable surface has shown no signs of wear after multiple seasons of intensive use, proving the tiles' resilience and long-term value. The quick installation prevented any impact on the school's sports programs or academic schedule.

Commitment to Trust: FAQ, Logistics, Warranty, and After-Sales Support

At the core of our offering for outdoor sport court tiles is an unwavering commitment to customer satisfaction and transparency. We aim to provide clear information on every aspect of your investment, from technical specifications to long-term support, building trust through comprehensive service.

Frequently Asked Questions (FAQ):

A: Our modular tiles are highly versatile and can be installed over various stable, flat sub-bases, including concrete, asphalt, or even compacted crushed stone. The critical factors are a level surface (tolerance of ±3mm over 3 meters) and adequate underlying drainage to prevent water accumulation. Detailed sub-base preparation guidelines are provided with every order to ensure optimal performance and longevity.

A: Engineered from high-grade, UV-stabilized polypropylene, our outdoor sport court tiles are designed to resist extreme temperatures (typically -30°C to +60°C), heavy rainfall, snow, and intense sunlight. The open grid design facilitates rapid drainage, preventing pooling and ice formation, ensuring year-round usability and minimizing weather-related downtime.

A: While professional installation is always recommended for optimal results, especially for large-scale or complex projects, the intuitive interlocking design of our tiles allows for relatively straightforward DIY installation for smaller courts, provided the sub-base is properly prepared. We offer comprehensive installation guides, video tutorials, and remote technical support to assist your team.

A: Court lines can be applied using specialized, durable acrylic paint designed for polypropylene surfaces, which offers excellent adhesion and wear resistance. For ultimate longevity and a seamless finish, we recommend integrating pre-fabricated colored tiles that form the lines directly into the court design. Both methods ensure a professional appearance that withstands heavy use and environmental exposure for many years.

Lead Time & Fulfillment: Efficient Global Logistics

Standard orders for our sport court tiles for sale typically have a lead time of 2-4 weeks from order confirmation to dispatch, depending on volume, specific customization requirements, and current production schedules. We operate with robust supply chain management and maintain significant inventory levels for popular products like the SES cushion tiles-E620 basketball court tiles. Expedited manufacturing and shipping options are available for urgent projects. We leverage strong global logistics partnerships to ensure efficient and trackable delivery worldwide, providing regular updates throughout the shipping process to keep clients informed.

Warranty & After-Sales Support: Protecting Your Investment

All our outdoor sport court tiles, including the SES cushion tiles-E620 basketball court tiles, are backed by a comprehensive 10-year limited warranty against manufacturing defects and material degradation under normal use and proper installation. This warranty reflects our confidence in the quality and longevity of our products. Our dedicated after-sales support team is readily available to assist with any technical queries, provide maintenance advice, or facilitate spare parts requirements. We are committed to fostering long-term relationships with our clients, ensuring your investment remains protected and performs optimally throughout its extensive lifespan, thereby maximizing your return on investment.

Conclusion

In conclusion, the strategic adoption of advanced outdoor sport court tiles represents a forward-thinking investment for any organization prioritizing player safety, durability, and operational efficiency. From their sophisticated manufacturing process and adherence to stringent international standards (e.g., ASTM F2772, FIBA) to their proven performance in diverse application scenarios (from basketball sport court tiles to pickleball sport court tiles), these modular surfaces offer a compelling alternative to traditional court constructions. By choosing a reputable vendor committed to quality, customization, and comprehensive support, stakeholders can ensure a high-performance, long-lasting, and aesthetically pleasing sport surface for years to come, maximizing both user satisfaction and financial return.

References:

- ASTM International. (n.d.). ASTM F2772 - Standard Specification for Indoor and Outdoor Court Surfaces for Multiple Sports. Retrieved from astm.org

- International Basketball Federation (FIBA). (n.d.). Basketball Equipment and Facilities. Retrieved from fiba.basketball

- International Organization for Standardization. (n.d.). ISO 9001:2015 Quality management systems – Requirements. Retrieved from iso.org

- European Chemicals Agency (ECHA). (n.d.). REACH regulation. Retrieved from echa.europa.eu

- U.S. Environmental Protection Agency. (n.d.). Polypropylene (PP) and Plastics. Retrieved from epa.gov

- DIN Deutsches Institut für Normung e. V. (n.d.). DIN 51130: Testing of floor coverings - Determination of the anti-slip properties - Walk method - Inclined plane. Retrieved from din.de

-

Durable Volleyball Ground Mats for Safe & Competitive Play

NewsNov.24,2025

-

Premium Volleyball Court Mat: Safety, Durability & Performance for Global Play

NewsNov.23,2025

-

Durable and Eco-Friendly Rubber Play Mats Outdoor for Safer Playgrounds

NewsNov.22,2025

-

Comprehensive Guide to Types of Interlock Tiles: Materials, Uses & Trends

NewsNov.22,2025

-

Exploring Different Types of Interlocking Tiles: Global Uses and Benefits

NewsNov.21,2025

-

PVC Interlocking Floor Tiles Price – Comprehensive Guide for Smart Flooring Choices

NewsNov.20,2025