Oct . 01, 2025 11:50 Back to list

Why Choose Vinyl Sports Flooring for Safe, Durable Play?

Field notes on vinyl sports flooring in 2025

If you’ve ever walked into a gym, thought “this feels fast,” and then checked your shoes, same. The surface matters. And right now, vinyl sports flooring is having a moment—driven by better foams, smarter coatings, and schools trying to do more with one hall. Funny twist: my latest site visit was actually to a hardwood install (we’ll get to that), which made the contrast clearer than ever.

What’s trending (and why it matters)

- Low-VOC, phthalate-free formulations; Greenguard-type emissions targets are becoming default.

- Thicker foam backings for safer landings in multi-sport halls—without killing ball rebound.

- Factory UV-PUR topcoats that actually resist black heel marks. Many customers say cleaning is “half the work” compared with older rolls.

- Hybrid thinking: pairing portable vinyl sports flooring over fixed wood during events. Sounds odd, but it’s happening.

Specs that coaches ask for (and testers verify)

Typical premium vinyl sports flooring (heterogeneous PVC + foam): thickness ≈ 4.5–8.0 mm; wear layer ≈ 0.5–1.2 mm; glass-fiber stabilization; PUR topcoat. Lab numbers (real-world use may vary): shock absorption 25–35% (EN 14904), ball rebound ≥ 90%, vertical deformation ≈ 1.8–3.5 mm, slip 80–110 (EN 14904 sliding).

From resin to game day: process, methods, tests

- Materials: phthalate-free PVC, plasticizers, glass-fiber grid, closed-cell foam, UV-PUR.

- Manufacture: calendering, lamination, embossing, UV-cure; master rolls conditioned 24–48h.

- Install: slab RH per ASTM F2170 or MVER per ASTM F1869, skim coat, adhesive trowel (A2/A3), 50–100 kg rolling, hot-weld seams, line-marking.

- Testing: EN 14904 (indoor sports), ASTM F2772, abrasion (ISO 5470-1), VOC (ISO 16000 / CA 01350).

- Service life: ≈ 8–12 years heavy use; 12–15 years in schools with good mats and maintenance.

Where it shines

Multi-purpose gyms, K-12 halls, basketball training, badminton, futsal, community centers, portable event courts. Water resistance and quick turnaround are the big wins. Compared with wood, vinyl sports flooring is more forgiving on budgets and floods—less so on elite hardwood “feel.” To be honest, players notice both.

Vendor snapshot (indicative)

| Vendor / Model | Core | Thickness | Shock Absorption | Certs | Lead Time |

|---|---|---|---|---|---|

| Gerflor Taraflex (various) | Vinyl + foam | 5–7 mm | ≈ 25–35% (EN 14904) | EN 14904, ISO 9001/14001 | ≈ 4–6 wks |

| Tarkett Omnisports | Vinyl + glass fiber | 5–8.5 mm | ≈ 25–40% | EN 14904, REACH | ≈ 4–8 wks |

| Enlio PVC Sports Series | Vinyl heterogeneous | 4.5–8 mm | ≈ 20–35% | EN 14904, BWF | ≈ 2–4 wks |

| Enlio Hardwood—The single-layer keel (benchmark) | Area-elastic wood | ≈ 70–90 mm system | ≈ 53–60% | EN 14904, FIBA | ≈ 6–10 wks |

Data representative; verify current spec sheets.

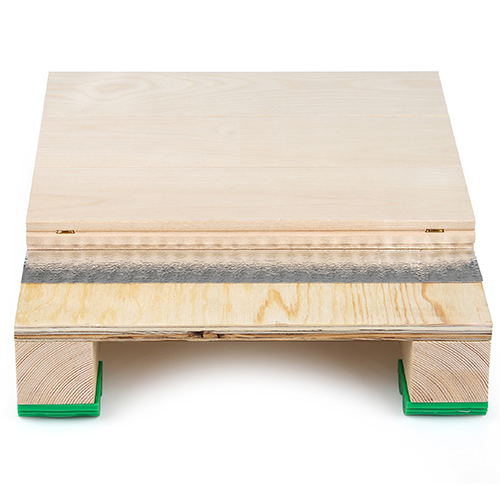

Product snapshot: Hardwood Sports Floor—The single-layer keel

Origin: 8th floor, Block B, ICC, No. 95, Cangyu Rd, Yuhua District, Shijiazhuang. Description: sports wood flooring system; often used as a benchmark against vinyl sports flooring for elite basketball feel.

| Structure | Single-layer keel understructure + hardwood top (exact species per project) |

| Performance | Shock ≈ 53–60%, Ball rebound ≥ 90% (EN 14904 class A4 target) |

| Service life | ≈ 20+ years with sanding cycles |

| Use cases | Basketball-first arenas; training courts |

Customization and real-world notes

- Options: thickness, foam density, colors, custom logos, acoustic underlays, fire rating (Bfl-s1 common).

- Industries: education, municipal sports, fitness, events, light indoor futsal.

- Users report: “less knee bite,” “easier cleaning,” and, surprisingly, “quieter PE classes.” I guess acoustics matter more than we admit.

Mini case notes

School gym, 1,200 m²: vinyl sports flooring at 6.5 mm achieved 31% shock and ≥ 95% rebound; turnover from handover to classes in 48 hours. Community hall: portable vinyl sports flooring roll system over concrete—zero moisture issues after RH testing (ASTM F2170) and epoxy primer.

Citations

- EN 14904: Surfaces for sports areas — Indoor surfaces for multi-sports use — Specifications.

- ASTM F2772: Standard Specification for Athletic Performance Properties of Indoor Sports Floor Systems.

- ISO 16000 / CA 01350: Indoor air emissions testing methods for VOCs.

- ISO 5470-1: Rubber- or plastics-coated fabrics — Determination of abrasion resistance.

-

Durable Volleyball Ground Mats for Safe & Competitive Play

NewsNov.24,2025

-

Premium Volleyball Court Mat: Safety, Durability & Performance for Global Play

NewsNov.23,2025

-

Durable and Eco-Friendly Rubber Play Mats Outdoor for Safer Playgrounds

NewsNov.22,2025

-

Comprehensive Guide to Types of Interlock Tiles: Materials, Uses & Trends

NewsNov.22,2025

-

Exploring Different Types of Interlocking Tiles: Global Uses and Benefits

NewsNov.21,2025

-

PVC Interlocking Floor Tiles Price – Comprehensive Guide for Smart Flooring Choices

NewsNov.20,2025