Oct . 24, 2025 12:45 Back to list

Outdoor Court Tiles: Durable, Non-Slip, Quick-Drain

A Pragmatic Guide to Outdoor Court Tiles: What’s Working Right Now

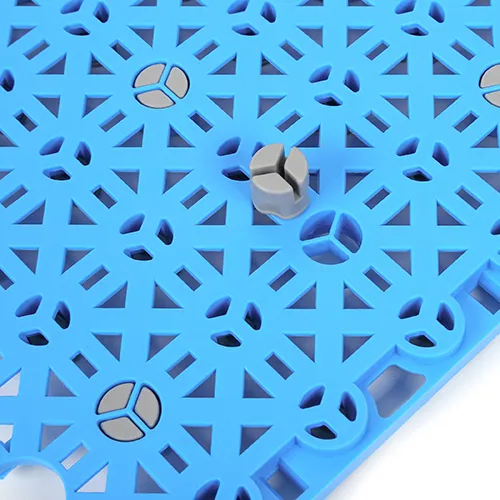

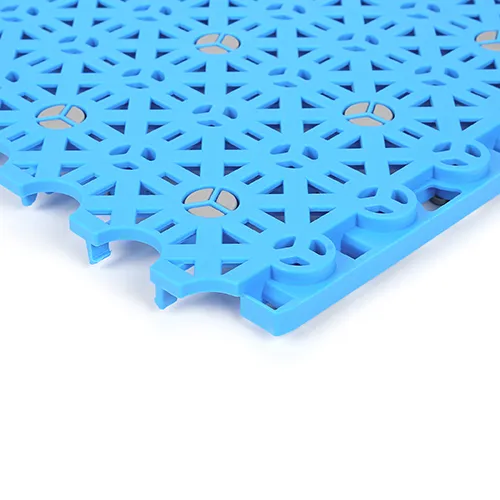

I’ve stepped on enough courts—sun-baked blacktop, cushioned modular decks, even those DIY backyard builds—to see how fast the market is evolving. Heat waves, heavier rain, and tighter recreation budgets are nudging facilities toward modular systems that install fast, drain faster, and don’t punish knees. Enlio’s SES cushion tiles-E620 (Basketball) are a good example of that shift. STRUCTURE-wise, they combine a rigid grid with an elastic underlayer—simple idea, big difference on impact.

Industry trends I’m seeing

- Climate-resilient surfacing: open-grid tiles that don’t pond water and shrug off UV fade.

- Squad-friendly installs: weekend retrofits over tired asphalt; minimal closure time.

- Safety-first specs: shock absorption targets and better wet traction, even after dust and pollen season.

- Customization: logos, school colors, multi-sport line sets—because community courts double as brand stages now.

Technical snapshot (SES cushion tiles‑E620)

To be honest, numbers don’t tell the whole story—but they do keep everyone honest. Below is a practical spec overview. Real-world results hinge on base prep and climate.

| Model | SES cushion tiles‑E620 (Basketball) |

| Material | UV‑stabilized PP copolymer + TPE elastic cushions |

| Tile size / thickness | ≈ 250×250 mm; ≈ 16±1 mm (real‑world use may vary) |

| Shock absorption | ≈ 18–22% (internal lab average ≈ 19%) |

| Ball rebound | ≈ 95% of rigid baseline (EN 12235 method; indicative) |

| Slip resistance | Pendulum (ASTM E303/EN 13036‑4): tuned for dry/wet balance |

| Temperature range | ≈ −40°C to +60°C; expansion joints recommended |

| Service life | Around 8–10 years with basic upkeep |

| Origin | 8th floor, Block B, ICC, No. 95, Cangyu Rd, Yuhua District, Shijiazhuang |

Materials, methods, and testing (the quick version)

Process flow: virgin PP + UV/HALS additives → color compounding → injection molding (tight mold controls to tame warpage) → post‑mold conditioning → dimensional and snap‑fit checks → impact and rebound testing → packaging. Test references typically include EN 14877 (outdoor sport surfaces), pendulum slip tests (ASTM E303/EN 13036‑4), ball bounce (EN 12235). Plants often carry ISO 9001/14001; material declarations (RoHS/REACH) can usually be supplied on request.

Where Outdoor Court Tiles make sense

- Municipal parks and schoolyards needing weekend renovations.

- Multi‑sport courts (basketball, futsal, volleyball) with quick line changes.

- Coastal or high‑UV regions—fade resistance really matters.

- Community centers wanting logos and color zoning for events.

Advantages: fast install over sound asphalt/concrete, forgiving underfoot feel, excellent drainage, modular maintenance (swap a tile, not a slab). Many coaches say the “day‑two” usability after rain is a game changer.

Vendor landscape (apples‑to‑apples-ish)

| Vendor/Model | Thickness | Shock Absorption | UV Warranty | Notes |

|---|---|---|---|---|

| Enlio SES E620 | ≈ 16 mm | ≈ 18–22% | Around 5–8 yrs | Basketball‑tuned cushions; strong drainage |

| Sport Court PowerGame+ | ≈ 15–19 mm | ≈ 20–25% | Varies by region | Well‑known league/brand installs |

| VersaCourt Game Outdoor | ≈ 15–19 mm | ≈ 15–20% | Varies | DIY‑friendly kits and ramps |

| SnapSports Outdoor | ≈ 15–20 mm | ≈ 15–22% | Varies | Fast clip systems; color breadth |

Specs are indicative; always check current datasheets in your market.

Customization and rollout

Color sets, Pantone‑matched center logos, pre‑painted lines, edging ramps—these are the knobs to turn. A typical rollout: site survey → base repair (crack fill, high‑spot grind) → tile layout and snap‑fit → line verification → logo install. I guess the main hiccup I see is people skipping expansion gaps; don’t.

Case notes from the field

A municipal school in Hebei retrofitted a cracked half‑court over a weekend with E620. After the first summer storm, the court reopened in under an hour—water went straight through. Feedback from PE staff: fewer slips on dusty mornings, and—surprisingly—less end‑of‑week knee fatigue for the frequent shooters. Not scientific, but it matches what many customers say about cushioned Outdoor Court Tiles.

Certs and compliance at a glance

Look for manufacturing under ISO 9001/14001, testing aligned with FIBA venue guidance, EN 14877, and pendulum friction standards. RoHS/REACH material statements are common requests for public tenders.

References

-

Durable Volleyball Ground Mats for Safe & Competitive Play

NewsNov.24,2025

-

Premium Volleyball Court Mat: Safety, Durability & Performance for Global Play

NewsNov.23,2025

-

Durable and Eco-Friendly Rubber Play Mats Outdoor for Safer Playgrounds

NewsNov.22,2025

-

Comprehensive Guide to Types of Interlock Tiles: Materials, Uses & Trends

NewsNov.22,2025

-

Exploring Different Types of Interlocking Tiles: Global Uses and Benefits

NewsNov.21,2025

-

PVC Interlocking Floor Tiles Price – Comprehensive Guide for Smart Flooring Choices

NewsNov.20,2025