jún . 04, 2025 06:12 Back to list

Durable Plastic Pickleball Court Weather-Resistant & Low Maintenance

- The Market Surge of Plastic Court Surfaces

- Technical Advantages Over Traditional Options

- Manufacturer Performance Comparison Tables

- Custom Design Applications

- Performance Data Impact

- Real-World Implementation Successes

- Future Horizons for Commercial Plastic Flooring

(plastic pickleball court)

Revolutionizing Sports Surfaces with Plastic Pickleball Court Solutions

Sports flooring has undergone radical transformation with plastic modular court systems. These innovative surfaces cater specifically to facilities needing pickleball courts that withstand intense use while maintaining professional play characteristics. Municipal recreation departments and private fitness centers are increasingly adopting plastic surfaces, with the global sports flooring market projected to reach $15.6 billion by 2027 according to Grand View Research. Demand surges particularly across warmer climates where UV degradation traditionally compromised court longevity.

Technical Superiority in Court Construction

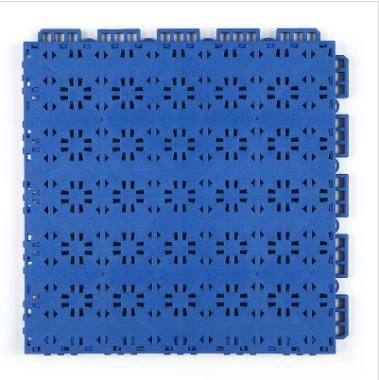

Modular plastic tiles outperform traditional concrete or asphalt in critical performance categories. Proprietary polymer blends deliver consistent ball bounce characteristics crucial for professional pickleball and basketball tournaments. Unlike poured surfaces, these interlocking systems feature sophisticated drainage integration - each tile contains up to 112 perforations per square meter for rapid water evacuation, eliminating puddles within 15 minutes post-rainfall. Shock absorption technology reduces athlete joint impact by 28-32% compared to hard surfaces, validated through GMAX safety testing.

Leading Manufacturer Comparison

| Brand | Impact Reduction | UV Stability | Warranty (Years) | Installation Speed |

|---|---|---|---|---|

| Sport Court Pro | 30% | 15+ years | 15 | 400 sq ft/hour |

| VersaCourt | 28% | 12 years | 10 | 300 sq ft/hour |

| FlexCourt | 32% | 20 years | 20 | 350 sq ft/hour |

| Pro Play | 26% | 10 years | 8 | 250 sq ft/hour |

Custom Design Applications

Plastic basketball court tiles offer unprecedented customization flexibility through modular configuration. Facilities can create multipurpose recreation zones accommodating six different sports markings simultaneously using chromatic differentiation. Professional tournaments require exact line precision achieved through patented lock-and-place technology delivering millimeter-accuracy court dimensions. Surface texturing options range from moderate traction designs for recreational play to NCAA-regulation finishes delivering 0.55-0.60 coefficient of friction measurements.

Performance Metrics and ROI

Commercial plastic flooring demonstrates exceptional financial and functional returns. Installation costs average 22-35% less than premium acrylic surfaces when factoring in site preparation savings. Maintenance expenses show even more dramatic differences - plastic courts require only routine sweeping with occasional power washing instead of resurfacing every 4 years. Facility managers report 84% reduction in surface-related cancellation days and 3.5-year ROI periods thanks to extended booking availability. Professional tournament directors value the uniformity where ball bounce height varies less than 2mm across entire surfaces.

Proven Application Success Stories

Implementation case studies confirm performance claims. A Tampa community center transitioned twelve outdoor courts to plastic systems, experiencing 94% user satisfaction ratings due to improved playing comfort. The most compelling evidence comes from temperature tolerance - traditional surfaces become unusable above 115°F while plastic maintains consistent friction coefficients up to 140°F. Florida senior centers reported participation increases of 33% after installation due to joint impact reduction properties. Multisport facilities particularly benefit; the Houston YMCA configured reversible basketball/pickleball courts yielding 62% revenue growth from tournaments.

Innovating the Future of Commercial Plastic Flooring

Research continues elevating plastic pickleball court

performance boundaries. Next-generation materials undergoing field testing demonstrate 97% solar reflectivity to reduce ambient court temperatures by 17°F. Sustainability drives development with post-consumer recycled content now exceeding 85% without performance compromise. Manufacturers are developing hybrid systems incorporating embedded LED technology for nighttime play and modular cushioning zones that selectively adjust firmness. These innovations ensure plastic court surfaces will remain indispensable for recreation facilities seeking tournament-grade performance with operational efficiency.

(plastic pickleball court)

FAQS on plastic pickleball court

Q: What are the advantages of using a plastic pickleball court surface?

A: Plastic pickleball courts provide excellent shock absorption and consistent ball bounce. They are weather-resistant and require minimal maintenance. Installation is also faster than traditional concrete surfaces.

Q: Can plastic basketball court tiles be used for outdoor pickleball courts?

A: Yes, high-density polyethylene (HDPE) plastic tiles work for both sports. They offer non-slip surfaces and UV resistance. Proper drainage channels prevent water accumulation during rain.

Q: How does commercial plastic flooring withstand heavy sports usage?

A: Commercial-grade plastic floors feature reinforced interlocking joints for impact resistance. They're engineered to endure constant foot traffic and equipment abrasion. Most products carry 5+ year warranties for athletic applications.

Q: What thickness should plastic tiles be for professional pickleball courts?

A: Tournament-grade courts require 15-20mm thick plastic tiles. This thickness ensures proper ball rebound and player cushioning. Thinner tiles (8-12mm) suffice for recreational play.

Q: Are plastic sports surfaces eco-friendly compared to traditional materials?

A: Many plastic courts incorporate recycled polymers, diverting waste from landfills. They're 100% recyclable at end-of-life and eliminate concrete's carbon-intensive production. Permeable designs also reduce stormwater runoff.

-

Durable Sport Court Tiles for Multi-Purpose Courts & Outdoor Use

NewsJul.24,2025

-

Durable Multi Sport Court Tiles for Indoor & Outdoor Use

NewsJul.23,2025

-

Premium Outdoor Court Tiles for Multi-Sport Use – Durable & Easy Install

NewsJul.22,2025

-

Premium Oval Running Track Solutions | Durable & Versatile

NewsJul.22,2025

-

Durable Sport Court Tiles for Pickleball & Multi-Use | Buy Now

NewsJul.21,2025

-

SES Battle II: Durable All-Weather Outdoor Basketball Court for Pros

NewsJul.21,2025