Sep . 10, 2025 09:20 Back to list

Best Vinyl Carpet Flooring: Durable, Waterproof & Easy Care

Introduction to Advanced vinyl carpet flooring Solutions

In the rapidly evolving landscape of commercial and industrial infrastructure, the selection of appropriate flooring materials is paramount to operational efficiency, safety, and long-term cost-effectiveness. Among the myriad options, vinyl carpet flooring has emerged as a leading solution, offering a unique blend of aesthetic versatility, robust performance, and low maintenance. This article delves into the technical intricacies, application benefits, and market dynamics of this advanced flooring technology, targeting B2B decision-makers and engineering professionals seeking durable, high-performance surfacing solutions.

Modern vinyl flooring is engineered to withstand rigorous conditions, making it an ideal choice for sectors demanding exceptional durability and hygiene. From high-traffic commercial spaces to specialized industrial environments, its layered construction provides superior resistance to abrasion, moisture, and chemical exposure. We will explore how its innovative design addresses critical challenges faced by various industries, offering a sustainable and economically viable alternative to traditional flooring options.

Industry Trends in High-Performance Flooring

The global flooring market is undergoing significant transformation, driven by demands for increased sustainability, advanced functional properties, and enhanced aesthetic appeal. Within this dynamic environment, vinyl flooring, including specialized variants like vinyl timber flooring and vinyl spc flooring, is experiencing substantial growth. Key trends indicate a shift towards products offering:

- Eco-Friendly Formulations: Manufacturers are increasingly focusing on phthalate-free vinyl, recycled content, and low VOC emissions to meet stringent environmental regulations and corporate sustainability goals.

- Rigid Core Technology: The proliferation of SPC (Stone Plastic Composite) and WPC (Wood Plastic Composite) vinyl flooring offers superior dimensional stability, making them ideal for areas with significant temperature fluctuations and heavy foot traffic. These innovations are blurring the lines between traditional hard flooring and flexible vinyl solutions.

- Enhanced Durability & Performance: Advancements in wear layer technology, such as ceramic bead or UV-cured urethane coatings, are extending service life and resistance to scratching, scuffing, and staining, particularly crucial for high-stress B2B applications.

- Design Versatility: Digital printing technologies allow for highly realistic reproductions of natural materials like wood and stone, alongside bespoke patterns, offering architects and designers unparalleled creative freedom for projects requiring a specific aesthetic without compromising performance.

- Acoustic Properties: Integrated acoustic backings are becoming standard, addressing noise reduction requirements in commercial spaces like offices, hospitals, and educational institutions, where sound dampening is critical for occupant comfort and productivity.

These trends underscore vinyl's adaptability and its pivotal role in modern architectural and engineering specifications. The integration of advanced materials and manufacturing processes ensures that vinyl solutions continue to meet the evolving demands of various industrial and commercial sectors.

Technical Specifications and Material Composition of Advanced Vinyl Flooring

Understanding the fundamental composition of modern vinyl carpet flooring is crucial for appreciating its performance characteristics. Typically, these flooring systems are multi-layered structures, each layer serving a specific function to contribute to the overall durability, stability, and aesthetic appeal.

- Wear Layer: This transparent top layer, often composed of a clear polyvinyl chloride (PVC) film with optional ceramic bead or urethane reinforcement, is critical for resistance against scratches, scuffs, and stains. Its thickness (measured in mils or millimeters) directly correlates with the product's durability and suitability for various traffic levels. Commercial-grade wear layers typically range from 20 to 40 mil (0.5 to 1.0 mm).

- Print Layer: Beneath the wear layer lies a high-definition printed film, which provides the visual aesthetic, mimicking natural materials such as wood grain (vinyl timber flooring), stone, or abstract patterns. Advanced photographic techniques ensure highly realistic and diverse design options.

- Core Layer: This is the primary structural component. In traditional flexible vinyl, it's typically a solid PVC layer reinforced with fiberglass for dimensional stability. For rigid core products (SPC/WPC), the core is composed of stone plastic composite (limestone powder and PVC) or wood plastic composite (wood flour and PVC), offering superior rigidity and impact resistance, making them highly resistant to indentations and temperature-induced expansion/contraction.

- Backing Layer: The base layer, often made of PVC or an integrated underlayment (e.g., IXPE foam), provides additional stability, sound absorption, and comfort underfoot. It also serves as a moisture barrier and facilitates easier installation.

Typical Vinyl Carpet Flooring Specifications

The following table outlines common technical parameters for high-performance vinyl carpet flooring, essential for specifying solutions in B2B contexts.

| Parameter | Value Range (Commercial Grade) | Relevant Standard / Test Method |

|---|---|---|

| Overall Thickness | 3.0 mm - 8.0 mm | ASTM F1700 / EN 430 |

| Wear Layer Thickness | 20 mil (0.5 mm) - 40 mil (1.0 mm) | ASTM F410 |

| Density | 1.8 - 2.2 g/cm³ (for SPC core) | ASTM D792 |

| Abrasion Resistance | Class 33-43 (Heavy Commercial to Very Heavy Industrial) | EN 660-2 (T-rating) |

| Residual Indentation | < 0.1 mm | EN 433 |

| Fire Resistance | Bfl-s1 (Europe) / Class A (North America) | EN 13501-1 / ASTM E648 |

| Slip Resistance | R9 - R11 (for textured surfaces) | DIN 51130 |

| VOC Emissions | Very Low, GreenGuard Gold certified | CDPH Section 01350 |

Figure 1: Cross-section illustrating the multi-layered composition of high-performance vinyl carpet flooring.

These specifications highlight the advanced engineering behind modern vinyl flooring, demonstrating its suitability for demanding commercial and industrial applications. The ability to meet rigorous international standards ensures reliability and compliance for critical infrastructure projects.

Manufacturing Process Flow of Vinyl Carpet Flooring

The production of high-quality vinyl carpet flooring involves a sophisticated, multi-stage manufacturing process that ensures material integrity, dimensional stability, and aesthetic consistency. Adherence to strict quality control protocols and international standards is maintained throughout the entire workflow.

Detailed Process Steps:

- Raw Material Preparation & Compounding:

High-grade PVC resins, plasticizers, stabilizers, fillers (e.g., calcium carbonate for SPC), and pigments are precisely weighed and mixed in industrial blenders. This compounding phase is critical for achieving the desired material properties, including flexibility, density, and color. For SPC flooring, limestone powder is meticulously blended with PVC resin.

- Core Layer Formation (Calendering or Extrusion):

- Calendering (for Flexible Vinyl): The compounded material is heated and fed through a series of rollers (calenders) to form a continuous, uniform sheet of the core layer. Fiberglass mesh is often embedded within this layer for enhanced dimensional stability.

- Extrusion (for Rigid Core SPC/WPC): The mixed SPC/WPC material is extruded through a die to form a rigid board. This process ensures high density and structural integrity, crucial for the click-lock systems.

- Print Film Application:

A high-resolution decorative film, digitally printed with desired patterns (wood, stone, abstract), is accurately laminated onto the core layer using heat and pressure. Precision alignment is essential for visual fidelity.

- Wear Layer & Protective Coating Application:

A clear PVC wear layer is applied over the print film, followed by additional protective coatings, often UV-cured urethane or ceramic bead enhancements. This significantly boosts abrasion, scratch, and chemical resistance, extending the product's service life.

- Curing and Stabilization:

The multi-layered sheet undergoes a controlled curing process, typically involving heat treatment, to cross-link polymers and enhance adhesion between layers. This step is vital for achieving optimal dimensional stability and preventing delamination.

- Cutting and Milling:

The cured material is then cut into planks or tiles of specified dimensions. For click-lock systems, precision CNC machining is employed to mill the interlocking edges, ensuring a tight, seamless fit during installation. This step demands extremely tight tolerances (e.g., ±0.05 mm) to guarantee product uniformity.

- Quality Control & Testing:

Throughout the entire process, rigorous quality control checks are performed. Finished products undergo a battery of tests, including:

- Dimensional Stability: (e.g., ISO 23999, ASTM F2199) ensuring minimal expansion/contraction.

- Peel Strength: (e.g., ASTM D903) to verify interlayer adhesion.

- Abrasion Resistance: (e.g., EN 660-2) to classify wear performance.

- Indentation Resistance: (e.g., EN 433) for impact durability.

- Color Fastness & UV Stability: (e.g., ISO 105-B02) to prevent fading.

Products are certified against international standards such as ISO 9001 for quality management and ISO 14001 for environmental management, along with product-specific standards like ASTM F1700 or EN 10582.

- Packaging & Logistics:

Finished flooring is meticulously packaged to prevent damage during transit and stored in climate-controlled warehouses before distribution to target industries such as petrochemical, metallurgy, and water supply & drainage, where its properties are highly valued.

This rigorous manufacturing process ensures that each panel of vinyl carpet flooring delivers exceptional performance, contributing to attributes like energy saving through enhanced thermal insulation and superior corrosion resistance in demanding operational environments.

Technical Advantages of Vinyl Carpet Flooring

The engineering design of modern vinyl carpet flooring confers a multitude of technical advantages that make it a preferred solution across diverse B2B applications. These benefits translate directly into operational efficiencies, cost savings, and enhanced facility performance.

- Exceptional Durability and Longevity: With multi-layer construction and robust wear layers, vinyl flooring exhibits superior resistance to heavy foot traffic, impacts, and abrasions. This extends its service life, significantly reducing replacement and maintenance costs compared to less durable alternatives. Commercial-grade vinyl can maintain its integrity for 15-25 years under proper conditions.

- Superior Water and Moisture Resistance: The non-porous nature of vinyl, especially rigid core variants, makes it virtually impervious to water penetration. This is critical for environments prone to spills, high humidity, or frequent cleaning, preventing issues like mold growth, warping, and subfloor damage.

- Chemical Resistance: Modern vinyl formulations are engineered to resist a wide array of chemicals, including acids, alkalis, and industrial cleaning agents. This attribute is invaluable in laboratories, healthcare facilities, and manufacturing plants where chemical spills are a possibility.

- Ease of Maintenance and Hygiene: The smooth, sealed surface of vinyl flooring prevents the accumulation of dirt, dust, and pathogens, making it exceptionally easy to clean and sanitize. This characteristic is vital for maintaining aseptic conditions in healthcare and food processing environments, minimizing operational downtime for cleaning.

- Acoustic Performance: Integrated backing layers and the inherent material properties of vinyl contribute to excellent sound absorption, reducing ambient noise levels. This is particularly beneficial in open-plan offices, educational settings, and patient care areas, enhancing comfort and productivity.

- Thermal Comfort and Insulation: Vinyl flooring offers better thermal insulation properties compared to ceramic or stone, contributing to more stable indoor temperatures and potential energy savings in climate-controlled environments.

- Dimensional Stability: Advanced core technologies (SPC/WPC) minimize expansion and contraction due to temperature fluctuations, ensuring the flooring remains stable and gap-free over time, even in large installations.

- Slip Resistance: Manufacturers offer vinyl flooring with various surface textures and coatings designed to meet specific slip resistance ratings (e.g., R9 to R11), enhancing safety in commercial and industrial settings, reducing the risk of slips and falls.

These advantages collectively position vinyl as a robust, versatile, and high-value flooring solution for demanding B2B applications, providing long-term performance and reliability.

Application Scenarios and Target Industries

The inherent versatility and robust performance characteristics of modern vinyl flooring, including specialized vinyl floor carpet and floor vinyl solutions, make it suitable for a wide array of demanding commercial and industrial applications. Its ability to mimic various textures, such as vinyl timber flooring, further broadens its appeal across diverse sectors.

- Healthcare Facilities: Hospitals, clinics, and laboratories require flooring that is hygienic, easy to sterilize, slip-resistant, and comfortable for staff. Vinyl's seamless installation, chemical resistance to disinfectants, and acoustic properties make it ideal for patient rooms, operating theaters, and corridors. Its non-porous surface prevents bacterial growth, crucial for infection control.

- Education Sector: Schools, universities, and daycare centers benefit from durable, low-maintenance, and sound-absorbing flooring. Vinyl withstands heavy foot traffic, resists stains from spills, and helps to reduce noise in classrooms and common areas, fostering a better learning environment.

- Retail & Hospitality: High-traffic retail stores, hotels, and restaurants demand aesthetically pleasing, highly durable, and easily cleanable flooring. Vinyl offers design flexibility to create inviting spaces while standing up to constant use, spills, and heavy equipment. Its rapid installation minimizes business disruption.

- Corporate Offices: For modern office environments, aesthetics, acoustics, and underfoot comfort are key. Vinyl carpet flooring provides a sophisticated look, reduces ambient noise, and offers ergonomic benefits, enhancing employee well-being and productivity.

- Light Industrial & Manufacturing: In areas like assembly lines, cleanrooms, and light manufacturing facilities, flooring needs to be resistant to chemicals, abrasion, and heavy machinery. Specialized industrial vinyl formulations offer robust protection and easy spill cleanup, supporting operational safety and efficiency.

- Sports Facilities: High-performance vinyl flooring, such as those used in gymnasiums and indoor courts (like the Enlio Table Tennis Court Mat 5.5 as an example of advanced vinyl applications), provides optimal shock absorption, consistent ball bounce, and high slip resistance for athletic safety and performance. These solutions are engineered for intensive use and specialized athletic demands.

- Transportation Hubs: Airports, train stations, and bus terminals require exceptionally durable and slip-resistant flooring for millions of passengers annually. Vinyl's resilience, ease of maintenance, and compliance with fire safety standards make it a reliable choice.

In specific scenarios, the advantages of vinyl are particularly pronounced:

- Energy Saving: In large commercial buildings, vinyl's insulating properties can contribute to improved thermal efficiency, reducing heating and cooling loads, and thus achieving significant energy savings over the building's lifecycle.

- Corrosion Resistance: For areas exposed to various chemicals or rigorous cleaning regimens, such as laboratories or food processing plants, the inherent chemical resistance of vinyl prevents material degradation, ensuring longevity and safety. This is critical in industries like petrochemical and water supply & drainage, where flooring must withstand corrosive substances and frequent wash-downs.

This broad applicability underscores the strategic value of investing in high-quality vinyl flooring solutions for long-term infrastructural integrity and operational excellence.

Vendor Comparison: Selecting the Optimal Vinyl Carpet Flooring Provider

The selection of a reliable vendor for vinyl carpet flooring is as critical as the product itself. B2B clients must consider not only technical specifications but also a vendor's reputation, support capabilities, and commitment to quality and sustainability. The following table provides a generalized comparison framework for evaluating potential suppliers.

Comparison of Leading Vinyl Flooring Providers (Illustrative Example)

| Feature/Criterion | Vendor A (e.g., Global Leader) | Vendor B (e.g., Specialized Innovator) | Vendor C (e.g., Regional Provider) |

|---|---|---|---|

| Product Range | Extensive: LVT, SPC, WPC, Sheet Vinyl, Sports Vinyl. Covers all related keywords like vinyl timber flooring, vinyl spc flooring, vinyl floor carpet. | Specialized: High-performance SPC & Sports Vinyl (e.g., Enlio-like solutions). Focus on durability and specific functional properties. | Standard: LVT & Flexible Sheet Vinyl for commercial use. Basic floor vinyl options. |

| Certifications & Compliance | ISO 9001, ISO 14001, GreenGuard Gold, CE, ASTM F1700, Phthalate-Free. | ISO 9001, CE, FIBA/ITF (for sports), EN 14904 (sports floors). Strong focus on specific industry standards. | ISO 9001, basic CE. Limited specialized certifications. |

| Customization Capabilities | High: Custom colors, patterns, logos, specialized coatings. | Moderate-High: Tailored performance specs, branding integration, specific texture requirements. | Limited: Standard catalog options. |

| Technical Support & Expertise | Global network, dedicated project managers, installation training, extensive technical documentation. | Specialized engineering support, deep product knowledge, direct technical consultation, on-site assistance for complex projects. | Standard sales support, basic installation guides. |

| Sustainability Practices | Robust: Recycled content, closed-loop manufacturing, low VOC, product transparency (EPDs). | Good: Phthalate-free, durable products for extended life, responsible sourcing. | Emerging: Basic recycling initiatives. |

| Warranty & Service Life | 10-25 years commercial warranty. 20+ years service life. | 15-20 years commercial/sports warranty. 15-25 years service life under heavy use. | 5-10 years commercial warranty. 10-15 years service life. |

This comparative analysis assists B2B clients in aligning their specific project requirements with the capabilities and strengths of various vinyl carpet flooring providers, ensuring an informed decision for long-term investment.

Customized Solutions and Design Integration

Beyond standard product offerings, the ability to provide customized vinyl carpet flooring solutions is a significant differentiator for B2B applications. Tailored flooring can meet unique aesthetic demands, precise functional specifications, and integrate seamlessly with complex architectural designs or branding guidelines.

- Bespoke Aesthetics: Digital printing technology allows for virtually limitless design possibilities. Clients can specify custom patterns, brand logos, intricate murals, or highly specific color palettes that complement their corporate identity or interior design scheme. This moves beyond standard vinyl timber flooring or abstract patterns, offering true uniqueness.

- Tailored Performance Characteristics: For specialized environments, physical properties can be customized. This includes modifying wear layer thickness for ultra-heavy traffic, integrating specific antimicrobial treatments for healthcare settings, adjusting slip-resistance coefficients for wet areas, or enhancing acoustic dampening for recording studios or auditoriums.

- Format and Installation Flexibility: While standard planks and tiles are common, custom-sized sheets or interlocking systems can be designed to facilitate rapid installation in large areas or minimize seams in sterile environments. Specific edge profiles can also be engineered for unique transition requirements.

- Integrated Wayfinding and Safety Markings: For commercial and industrial facilities, customized vinyl flooring can incorporate permanent directional arrows, safety zones, social distancing markers, or hazard warnings directly into the floor design, improving facility navigation and worker safety without requiring adhesive overlays.

- Environmental & Health Compliance: Custom solutions can be engineered to meet specific regional or industry-specific environmental and health standards, such as ultra-low VOC emissions for sensitive populations or specific fire ratings for high-risk zones, going beyond general certifications.

Engaging with manufacturers who possess advanced R&D capabilities and flexible production lines enables B2B clients to realize highly specialized flooring solutions that are precisely aligned with their project vision and operational demands.

Real-World Application Case Studies

The practical advantages of vinyl carpet flooring are best exemplified through its successful implementation in diverse industrial and commercial projects. These case studies highlight how engineered vinyl solutions address specific challenges and deliver measurable benefits.

Case Study 1: High-Traffic Retail Chain Renovation

Client: A prominent national retail chain with over 200 stores.

Challenge: Existing ceramic tile flooring was prone to chipping, difficult to clean, and offered poor acoustic comfort, leading to high maintenance costs and a noisy shopping environment. The client required a durable, aesthetically pleasing, and quickly installable solution to minimize store downtime.

Solution: Installation of 6.5mm thick vinyl spc flooring with a 28 mil (0.7 mm) wear layer, featuring a vinyl timber flooring aesthetic. The click-lock system allowed for rapid installation (average 2,000 sq ft per day per crew) over the existing subfloor, eliminating extensive demolition. The integrated acoustic backing reduced noise by an average of 12 dB.

Outcome: The new flooring significantly reduced maintenance costs by 30% annually due to its ease of cleaning and superior stain resistance. Customer feedback indicated a more pleasant shopping experience due to reduced noise. The flooring demonstrated excellent wear resistance after 3 years, with no visible signs of deterioration despite daily heavy foot traffic from over 10,000 visitors per store.

Case Study 2: Pharmaceutical Cleanroom Upgrade

Client: A leading pharmaceutical manufacturing facility requiring ISO Class 7 cleanroom standards.

Challenge: The previous epoxy flooring was showing signs of cracking and chemical degradation, posing a contamination risk and requiring frequent, costly repairs. The facility needed a seamless, highly chemical-resistant, and anti-static floor vinyl solution with minimal particulate shedding.

Solution: Implementation of a specialized 3.0mm homogeneous sheet vinyl carpet flooring with welded seams and an integrated anti-static conductive layer. The material was selected for its high resistance to common cleanroom chemicals (e.g., isopropyl alcohol, hydrogen peroxide) and its non-shedding properties. Installation was performed in sections during planned shutdowns to ensure continuous operations.

Outcome: The new vinyl flooring provided a completely seamless, sterile surface that met ISO Class 7 particulate requirements. Post-installation testing confirmed optimal anti-static performance (surface resistance of 10^6 - 10^8 Ohms). The flooring has been in service for 5 years without any signs of chemical degradation or cracking, resulting in zero contamination incidents attributable to flooring failure and reduced cleaning cycle times by 15% due to its superior cleanability.

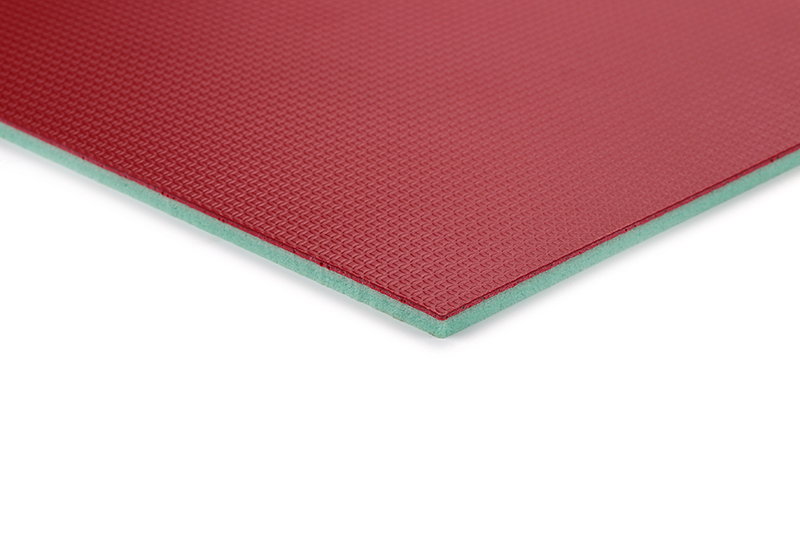

Figure 2: Vinyl carpet flooring in a commercial setting, demonstrating design versatility and functional performance.

Case Study 3: University Sports Hall Upgrade (Ref. Enlio Mat)

Client: A major university upgrading its multi-purpose sports hall.

Challenge: The existing sports flooring offered inconsistent ball bounce, inadequate shock absorption, and frequent slip hazards, leading to athlete injuries and poor training conditions. A durable, high-performance, multi-sport compliant surface was required.

Solution: Installation of a professional-grade multi-layer vinyl sports flooring system, similar in principle to the high-performance characteristics of products like the Enlio Table Tennis Court Mat 5.5, designed for optimal shock absorption and energy return. This specialized floor vinyl featured an integrated foam backing and a textured wear layer.

Outcome: The new flooring significantly enhanced athlete safety and performance. Impact absorption improved by 25% (as per EN 14904 testing), reducing stress on joints. The uniform surface provided consistent ball bounce for various sports, and the optimized friction coefficient drastically reduced slip incidents. The university reported increased usage of the facility and positive feedback from athletic teams. The projected service life is 15 years under intensive daily use.

These case studies underscore the reliability, performance, and long-term value proposition of engineered vinyl flooring solutions across a spectrum of demanding B2B environments.

Ensuring Trust: Certifications, Authoritative References, and Testing Data

In the B2B sector, trust and reliability are paramount. This is especially true for critical infrastructure components like flooring. Reputable manufacturers of vinyl carpet flooring demonstrate their commitment to quality and performance through rigorous third-party certifications, adherence to authoritative standards, and transparent reporting of testing data.

- ISO Certifications: Compliance with ISO 9001 (Quality Management Systems) and ISO 14001 (Environmental Management Systems) assures clients of a structured, quality-focused manufacturing process and a commitment to environmental responsibility. Many leading providers also hold ISO 45001 (Occupational Health and Safety).

- Product-Specific Performance Standards: Adherence to international standards such as ASTM International (e.g., ASTM F1700 for resilient flooring, ASTM E648 for critical radiant flux), European Norms (EN 10582 for homogeneous and heterogeneous vinyl floor coverings, EN 660-2 for abrasion resistance), and DIN standards (e.g., DIN 51130 for slip resistance) verifies that the flooring meets predefined performance benchmarks suitable for commercial and industrial use.

- Environmental Certifications: Certifications like GreenGuard Gold, FloorScore, and Cradle to Cradle reflect a product's low chemical emissions and lifecycle sustainability, crucial for projects aiming for LEED or WELL Building Standard certifications. These assure minimal impact on indoor air quality.

- Fire Safety Ratings: Compliance with critical fire safety standards (e.g., EN 13501-1 for Europe, NFPA 253/ASTM E648 for North America) is essential for public and commercial buildings, ensuring products meet specific flame spread and smoke development criteria.

- Independent Test Data: Verifiable data from independent laboratories on parameters like residual indentation, dimensional stability, chemical resistance, and acoustic performance provides objective evidence of product capabilities. Leading vendors readily supply product data sheets (PDS) and safety data sheets (SDS).

- Partner Clients & Years of Service: A strong portfolio of long-term partnerships with reputable enterprises and extensive years of service in the industry (e.g., 20+ years) serve as practical validation of a vendor's reliability and product quality. Customer feedback and testimonials further reinforce this trust.

By emphasizing these authoritative references and transparent data, B2B clients can make informed decisions, confident in the long-term performance and compliance of their selected vinyl flooring solutions.

Frequently Asked Questions (FAQ) about Vinyl Carpet Flooring

Q1: What is the typical service life of commercial-grade vinyl flooring?

A1: High-quality commercial-grade vinyl carpet flooring, with appropriate wear layer thickness and proper maintenance, typically offers a service life of 15 to 25 years. Specialized industrial or sports vinyl can also achieve similar longevity under extreme use conditions.

Q2: Is vinyl flooring resistant to harsh chemicals?

A2: Yes, modern vinyl formulations are engineered for excellent chemical resistance. They can withstand exposure to many common acids, alkalis, solvents, and industrial cleaning agents without degradation. However, it's always recommended to check specific product data sheets for resistance to particular chemicals relevant to your facility.

Q3: How does vinyl flooring contribute to acoustics in a commercial space?

A3: Vinyl flooring, especially those with integrated acoustic backings, effectively absorbs impact sound and reduces sound transmission. This leads to quieter environments, crucial for offices, healthcare facilities, and educational institutions where noise reduction enhances comfort and productivity.

Q4: Can vinyl carpet flooring be installed over existing subfloors?

A4: In many cases, yes. Rigid core SPC/WPC vinyl flooring, in particular, can often be installed directly over existing hard surface subfloors (e.g., concrete, ceramic tile, plywood) provided the subfloor is clean, dry, level, and structurally sound. This can significantly reduce preparation time and costs. Always follow the manufacturer's specific installation guidelines.

Q5: What are the environmental credentials of modern vinyl flooring?

A5: Modern vinyl flooring has significantly improved its environmental profile. Many products are phthalate-free, contain recycled content, are 100% recyclable, and achieve low VOC emissions certifications like GreenGuard Gold or FloorScore. Manufacturers are increasingly focused on lifecycle assessments and product transparency through Environmental Product Declarations (EPDs).

Procurement & Support: Lead Time, Warranty, and After-Sales Service

For B2B clients, the procurement and post-sales support aspects of vinyl carpet flooring are as vital as the product itself, influencing project timelines, budget adherence, and long-term satisfaction.

Lead Time & Fulfillment Details:

Typical lead times for standard floor vinyl products range from 2-4 weeks for ex-stock items, extending to 6-12 weeks for custom orders or large-scale projects requiring specialized manufacturing. This includes production, quality control, and shipping. Expedited shipping options are often available for urgent requirements, though they may incur additional costs. Reputable vendors maintain robust supply chains and transparent communication channels to provide accurate lead time estimates and proactive updates on order status, ensuring project schedules are met.

Warranty Commitments:

Commercial warranties for vinyl carpet flooring typically range from 10 to 25 years, covering manufacturing defects, wear-through, fading, and delamination under normal commercial use and proper maintenance. These warranties underscore the manufacturer's confidence in product durability. Specific terms and conditions, including maintenance requirements, are detailed in the warranty document, which clients should thoroughly review to ensure coverage aligns with their operational environment.

Customer Support & After-Sales Service:

Comprehensive customer support is a hallmark of a professional vendor. This includes:

- Technical Assistance: Providing expert guidance on product selection, installation methods, subfloor preparation, and compatibility issues.

- Maintenance Guidelines: Detailed instructions and recommendations for cleaning, stain removal, and routine care to maximize the flooring's lifespan and appearance.

- Issue Resolution: Prompt and efficient handling of any concerns, claims, or performance issues that may arise post-installation, often backed by a dedicated customer service team and field representatives.

- Training Resources: Offering educational materials or workshops for installation teams and facility managers to ensure optimal product handling and maintenance.

A strong emphasis on these support pillars ensures that clients receive not just a product, but a complete, reliable flooring solution backed by expert assistance throughout its entire lifecycle.

Conclusion: The Future of High-Performance Flooring

As industries continue to demand resilient, versatile, and sustainable material solutions, vinyl carpet flooring stands out as a preeminent choice for B2B applications. Its advanced multi-layer construction, robust technical specifications, and proven performance across a myriad of challenging environments—from high-traffic retail to sterile pharmaceutical cleanrooms and specialized sports facilities—underscore its strategic value.

The continuous innovation in materials science and manufacturing processes ensures that vinyl flooring will remain at the forefront of high-performance surface solutions. By carefully evaluating industry trends, technical data, and vendor capabilities, B2B decision-makers can confidently invest in vinyl carpet flooring, securing long-term operational benefits, enhanced safety, and aesthetic excellence for their facilities.

The commitment to comprehensive support, transparent warranties, and adherence to global standards further solidifies its position as a trusted and indispensable component in modern commercial and industrial infrastructure projects.

References

- ASTM International. (n.d.). Standard Specification for Resilient Floor Tile. Retrieved from www.astm.org

- European Committee for Standardization. (n.d.). EN 10582: Resilient floor coverings - Homogeneous and heterogeneous polyvinyl chloride floor coverings - Specification. Retrieved from www.cenelec.eu

- GreenGuard Environmental Institute. (n.d.). Certification Standards. Retrieved from www.greenguard.org

- ISO International Organization for Standardization. (n.d.). ISO 9001 Quality management systems. Retrieved from www.iso.org

- The Resilient Floor Covering Institute. (n.d.). FloorScore Standard for Indoor Air Quality. Retrieved from www.rfci.com

- DIN Deutsches Institut für Normung. (n.d.). DIN 51130: Testing of floor coverings - Determination of the anti-slip properties - Wet-loaded areas - Walking method - Ramp test. Retrieved from www.din.de

-

Durable Volleyball Ground Mats for Safe & Competitive Play

NewsNov.24,2025

-

Premium Volleyball Court Mat: Safety, Durability & Performance for Global Play

NewsNov.23,2025

-

Durable and Eco-Friendly Rubber Play Mats Outdoor for Safer Playgrounds

NewsNov.22,2025

-

Comprehensive Guide to Types of Interlock Tiles: Materials, Uses & Trends

NewsNov.22,2025

-

Exploring Different Types of Interlocking Tiles: Global Uses and Benefits

NewsNov.21,2025

-

PVC Interlocking Floor Tiles Price – Comprehensive Guide for Smart Flooring Choices

NewsNov.20,2025