Aug . 31, 2025 02:20 Back to list

Outdoor Multipurpose Outdoor Sports Court | Durable & Versatile

Industry Trends and Market Dynamics for Multi-Purpose Sports Courts

The global demand for versatile and sustainable sporting infrastructure is experiencing robust growth, driven by urbanization, increased focus on public health, and the need for cost-effective recreational solutions. A key component of this trend is the outdoor multipurpose outdoor sports court, which offers communities, educational institutions, and private enterprises a highly adaptable platform for various athletic activities. Market analytics project a compound annual growth rate (CAGR) exceeding 6% for the sports flooring market, with multi-sport surfaces being a significant contributor, reaching an estimated USD 15 billion by 2027. This growth underscores a shift towards integrated sports facilities that maximize utility and minimize spatial footprint, aligning with modern urban planning principles and community development goals.

Clients are increasingly seeking solutions that offer durability, low maintenance, and superior player safety, coupled with aesthetic flexibility. The integration of advanced materials and manufacturing techniques allows for the creation of surfaces that can withstand diverse climatic conditions while providing optimal performance characteristics for sports ranging from basketball and tennis to volleyball and futsal. This strategic investment in a single, high-performance surface reduces the need for multiple specialized courts, optimizing capital expenditure and operational costs for municipalities, schools, and private sports complexes.

Manufacturing Process and Material Science for a Superior Sports Surface

The construction of a high-quality outdoor multipurpose outdoor sports court involves a meticulous manufacturing process, leveraging cutting-edge material science and stringent quality control. Our courts primarily utilize advanced modular interlocking tiles, typically crafted from virgin polypropylene (PP), a robust thermoplastic polymer known for its excellent impact resistance, chemical stability, and UV resistance.

Process Flow:

- Material Sourcing & Preparation: High-grade virgin PP granules are selected, often incorporating UV stabilizers, anti-aging agents, and color pigments to ensure long-term performance and aesthetic integrity under direct sunlight and harsh weather conditions.

- Injection Molding: The prepared PP blend is fed into high-precision injection molding machines. Here, it is heated to a molten state and injected under high pressure into meticulously designed molds. These molds define the specific dimensions, interlocking mechanism, and surface texture of each tile, ensuring uniform thickness and structural integrity. CNC machining is crucial in creating these precise molds.

- Cooling & Demolding: After injection, the molten plastic is rapidly cooled within the mold to solidify. Once cooled, the individual tiles are demolded, ready for inspection.

- Surface Treatment & Finishing: Depending on the court type, tiles may undergo additional surface treatments to enhance grip, reduce glare, or improve specific playing characteristics. This stage ensures optimal traction and player safety.

- Quality Assurance & Testing: Each batch of tiles undergoes rigorous testing. This includes dimensional checks, impact resistance tests (e.g., ASTM F2769-11 for shock absorption), anti-slip testing (e.g., AS/NZS 4586), UV degradation tests, and color consistency checks. Products adhere to international standards such as ISO 9001 for quality management and ISO 14001 for environmental management, ensuring consistent, high-performance output.

- Packaging & Dispatch: Approved tiles are then carefully packaged for transport to installation sites.

The selection of virgin PP ensures superior material properties compared to recycled alternatives, offering enhanced longevity and structural stability. This translates to an estimated service life of 10-15 years or more under typical outdoor conditions, depending on usage intensity and maintenance. Target industries for these durable surfaces include municipal recreation departments, educational institutions (schools, universities), private sports clubs, and residential complexes.

In typical application scenarios, the material's inherent properties provide significant advantages. Its non-porous surface prevents water absorption, mitigating frost heave damage in cold climates and accelerating drainage during heavy rainfall, thus extending playing availability. Furthermore, the material's chemical inertness offers excellent corrosion resistance, making it suitable for environments with diverse atmospheric conditions or even light chemical exposure, far surpassing the limitations of traditional asphalt or concrete courts which degrade significantly over time.

Figure 1: High-precision injection molding for durable sports tiles.

Technical Specifications and Performance Parameters

Understanding the precise technical specifications of an outdoor multipurpose outdoor sports court is crucial for B2B decision-makers. These parameters dictate the court's performance, durability, and safety, ensuring it meets the rigorous demands of competitive play and heavy recreational use. Our modular interlocking tile systems are engineered for superior athletic experience and longevity.

Product Specification Table: Modular Interlocking Sports Tile

| Parameter | Specification | Benefit / Standard Compliance |

|---|---|---|

| Material Composition | 100% Virgin Polypropylene (PP) with UV Stabilizers | Exceptional durability, environmental resistance, non-toxic, recyclable. |

| Tile Dimensions | Typically 25cm x 25cm to 30.48cm x 30.48cm (10"x10" to 12"x12") | Modular design for easy installation, replacement, and customization. |

| Tile Thickness | 1.27cm - 1.58cm (0.5" - 0.625") | Optimized for structural stability and controlled impact absorption. |

| Shock Absorption (Force Reduction) | 10% - 25% (Meets EN 14877 / ASTM F2769-11) | Reduces player fatigue and risk of impact-related injuries, enhancing safety. |

| Vertical Deformation | 0.9mm - 1.5mm (Meets EN 14877) | Provides consistent ball bounce and energy return, enhancing playability. |

| Sliding Friction (Coefficient) | 0.5 - 0.7 (Meets EN 13036-4 / AS/NZS 4586) | Optimal grip for quick directional changes, preventing slips while allowing safe pivots. |

| Temperature Resistance | -30°C to +70°C (-22°F to +158°F) | Suitable for extreme climates without degradation or warping. |

| UV Stability | Fade resistance (e.g., Delta E | Maintains color vibrancy and material integrity despite prolonged sun exposure. |

| Drainage Capability | Self-draining surface design (perforated or elevated) | Rapid water evacuation, preventing pooling and allowing quick return to play after rain. |

| Fire Rating | Typically Bfl-s1 (European Standard EN 13501-1) | Ensures safety compliance in public spaces with stringent fire regulations. |

| Warranty | 10-15 Years Limited Manufacturer Warranty | Industry-leading guarantee on material integrity and performance. |

These specifications are not merely numbers; they represent a commitment to engineering excellence. For example, the balanced coefficient of sliding friction (0.5-0.7) is critical. A surface that is too slippery poses a fall risk, while one that is too sticky can cause joint injuries due to excessive rotational resistance. Our surfaces are designed to provide the ideal balance, ensuring player safety without compromising dynamic movement.

Technical Advantages: Performance, Durability, and ROI

Investing in a high-quality outdoor multipurpose outdoor sports court yields significant technical advantages that translate directly into operational efficiencies and long-term value for B2B clients.

- Superior Durability & Longevity: Constructed from advanced virgin polypropylene, these courts exhibit exceptional resistance to abrasion, impact, and fatigue. Unlike traditional hard courts that crack and degrade over time due to thermal expansion/contraction, modular tiles allow for natural movement, preventing surface damage. This ensures a significantly extended service life, reducing the frequency and cost of major refurbishments.

- Optimal Player Safety: The engineered shock absorption properties (force reduction up to 25%) significantly mitigate impact forces on players' joints and ligaments, reducing the risk of injuries common on harder surfaces. The consistent, controlled ball bounce and anti-slip surface texture further contribute to a safer and more enjoyable playing environment.

- All-Weather Performance: The self-draining design of interlocking tiles ensures rapid water runoff, preventing pooling and making courts playable almost immediately after rain. Integrated UV stabilizers protect against sun degradation and color fading, maintaining aesthetic appeal and material integrity across diverse climate zones, from extreme heat to freezing temperatures.

- Low Maintenance Requirements: The non-porous surface resists staining, mold, and mildew. Routine cleaning typically involves sweeping or hosing down, drastically reducing labor and material costs associated with asphalt or acrylic court resurfacing and crack repairs. Damaged tiles can be replaced individually, avoiding costly full-surface overhauls.

- Environmental Sustainability: Made from recyclable PP, these courts offer an environmentally conscious alternative. Their long lifespan and reduced need for chemical maintenance also contribute to a lower environmental footprint compared to traditional court materials that may require sealing or specific waste disposal protocols.

- Rapid Installation & Cost Efficiency: The interlocking modular design allows for swift installation over any flat, stable sub-base, including existing worn-out courts. This significantly reduces installation time and labor costs compared to poured or painted surfaces. The long lifespan and low maintenance further enhance the total cost of ownership (TCO) over the product's lifecycle, offering a superior return on investment (ROI).

Application Scenarios and Exemplary Case Studies

The inherent versatility of an outdoor multipurpose outdoor sports court makes it an ideal solution across a broad spectrum of B2B applications. Its adaptability allows for seamless integration into various recreational and athletic environments, fulfilling diverse community and organizational needs.

Key Application Scenarios:

- Educational Institutions: Schools, colleges, and universities utilize these courts for physical education classes, intramural sports, and official team practices, accommodating basketball, tennis, volleyball, and more on a single surface.

- Municipal & Community Parks: Local governments invest in these courts to provide accessible, safe, and durable recreational facilities for public use, fostering community engagement and health.

- Sports Clubs & Training Centers: Professional and amateur sports organizations benefit from high-performance surfaces that can withstand intensive training regimes and host multiple sports.

- Residential & Commercial Developments: High-end residential communities, hotels, resorts, and corporate campuses integrate multi-purpose courts as premium amenities, enhancing property value and occupant satisfaction.

- Military Bases & Government Facilities: Providing recreational outlets for personnel, requiring robust and low-maintenance solutions.

Exemplary Case Studies:

Case Study 1: Urban Community Sports Hub (Asia Pacific)

A rapidly developing city sought to revitalize an underutilized public space into a vibrant sports hub. They chose our modular sports court system to create a central multi-sport arena. The project involved converting a deteriorated concrete slab into a state-of-the-art facility supporting basketball, futsal, and badminton. The installation, completed in just 7 days, allowed the community to quickly gain access to high-quality sports infrastructure. Post-installation feedback highlighted the court's excellent drainage, vibrant aesthetics, and significantly improved player comfort compared to the previous asphalt surface. The facility now hosts daily recreational play and weekend tournaments, boosting local engagement and public health initiatives.

Case Study 2: Private University Athletic Department (North America)

A prestigious university required an upgrade to its outdoor athletic facilities to better serve its growing student population and competitive sports teams. The challenge was to install a durable, high-performance surface that could withstand harsh winter conditions and intense year-round use. Our modular interlocking court was selected for its proven freeze-thaw resistance and low maintenance profile. The new surface replaced outdated tennis courts and a dilapidated basketball court, consolidating several sports into one adaptable area. The university reported a substantial reduction in maintenance costs and a positive impact on student athlete recruitment, attributing it to the superior playing experience and modern aesthetic of the new facility.

Figure 2: A vibrant multi-purpose court enhancing community engagement.

Vendor Comparison: Evaluating Multi-Sport Surface Solutions

When selecting an outdoor multipurpose outdoor sports court, B2B clients must navigate a landscape of various material types and vendor offerings. A comprehensive comparison is essential to ensure the chosen solution aligns with performance requirements, budget constraints, and long-term operational goals. The market offers several prominent options, each with distinct advantages and disadvantages.

Product Comparison Table: Common Outdoor Sports Surface Types

| Feature/Type | Modular Interlocking PP Tiles (Our Solution) | Acrylic Hard Court (e.g., Plexipave) | Asphalt/Concrete with Paint |

|---|---|---|---|

| Primary Material | Virgin Polypropylene | Acrylic resins, silica sand, rubber granules | Asphalt or concrete base, acrylic/epoxy paint |

| Installation Time | Days (rapid, modular) | Weeks (requires specialized labor, curing time) | Weeks (requires extensive base preparation, curing) |

| Sub-Base Requirements | Flat, stable surface (concrete, asphalt, compacted aggregate) | High-quality, crack-free asphalt or concrete base | Extensive, perfectly level base construction |

| Player Safety (Shock Absorption) | Excellent (10-25% force reduction) | Moderate (some cushioning possible with rubber layers) | Poor (very hard, high impact on joints) |

| Maintenance & Repair | Very low; easy individual tile replacement | Moderate; requires periodic resurfacing, crack filling | High; frequent crack repair, repainting, prone to fading |

| Weather Resistance | Excellent (UV stable, rapid drainage, temp resistant) | Good (prone to cracking in freeze-thaw cycles) | Poor (cracking, fading, poor drainage) |

| Expected Lifespan | 10-15+ years | 5-10 years (before major resurfacing) | 3-7 years (before significant degradation) |

| Total Cost of Ownership (TCO) | Low (initial + maintenance) | Medium to High (initial + frequent maintenance) | High (low initial, but high repair/replacement) |

This comparison highlights the inherent advantages of modular interlocking tiles, particularly in terms of long-term value and operational efficiency. While initial costs for some traditional surfaces might appear lower, the cumulative expenses associated with frequent maintenance, repair, and shorter lifespans often result in a significantly higher total cost of ownership. Our solutions prioritize durability, performance, and ease of maintenance, offering a superior return on investment.

Customized Solutions for Unique Project Requirements

Recognizing that no two projects are identical, we specialize in delivering highly customized outdoor multipurpose outdoor sports court solutions. Our consultative approach ensures that every aspect of the court design, functionality, and aesthetic aligns perfectly with the client's specific vision, operational needs, and site constraints.

Key Areas of Customization:

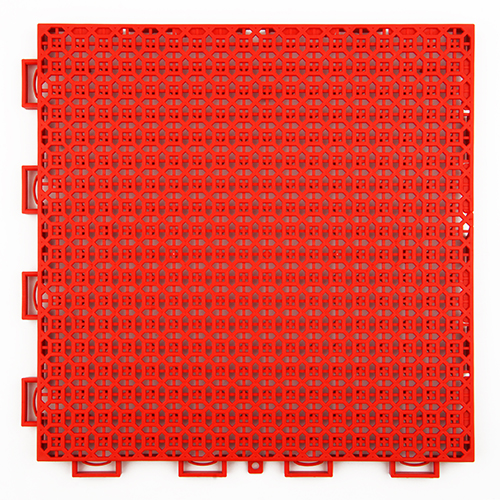

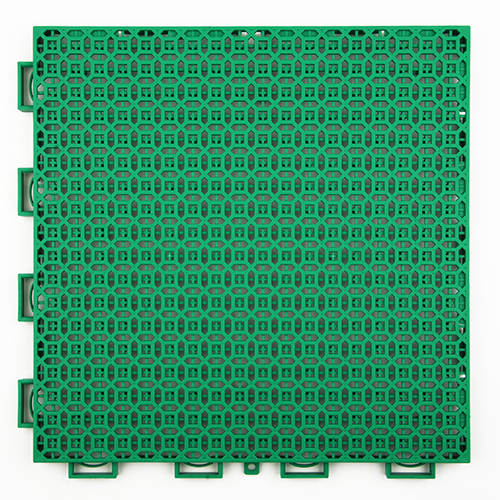

- Surface Configuration & Color Schemes: Clients can select from a wide palette of colors to match branding, school colors, or architectural aesthetics. Multi-color layouts can delineate different playing zones or create visually striking designs.

- Integrated Line Markings: Custom line markings for multiple sports (e.g., basketball, tennis, volleyball, pickleball, futsal) are precisely applied or integrated into the tile design, ensuring accurate dimensions and long-lasting visibility.

- Branding & Logo Integration: Corporate logos, school emblems, or sponsor branding can be seamlessly incorporated into the court surface, enhancing identity and marketing opportunities.

- Accessory Integration: We offer comprehensive solutions including perimeter fencing, lighting systems (LED for energy efficiency), player benches, scoreboards, and multi-sport net systems, all designed to complement the court and enhance the overall facility.

- Sub-Base Preparation & Installation: Our technical team provides expert guidance on optimal sub-base preparation, whether it involves concrete, asphalt, or compacted aggregate, ensuring maximum court performance and longevity. We can also provide full installation services or supervision.

- Performance Optimization: Depending on the primary sports intended, specific tile designs or underlayment options can be recommended to optimize characteristics such as ball bounce, energy return, or impact absorption for a tailored playing experience.

Our project managers work closely with architects, facility managers, and stakeholders from concept to completion, ensuring a bespoke solution that exceeds expectations and provides lasting value.

Trustworthiness & Client Support: Our Commitment to Excellence

Establishing trust and ensuring long-term client satisfaction are paramount. We stand behind the quality and performance of our outdoor multipurpose outdoor sports court solutions through comprehensive certifications, transparent processes, and robust support infrastructure.

Authoritative Certifications & Standards:

Our products and manufacturing processes adhere to the highest international standards, including:

- ISO 9001: Certified Quality Management System, ensuring consistent product quality and customer satisfaction.

- ISO 14001: Environmental Management System, demonstrating our commitment to sustainable and eco-friendly manufacturing.

- CE Certification: Compliance with European Union safety, health, and environmental protection requirements.

- RoHS Compliance: Restriction of Hazardous Substances Directive, affirming the absence of harmful materials.

- ASTM F2769-11: Standard Specification for Indoor and Outdoor Sport Surfacing, for critical safety parameters like shock absorption.

- EN 14877: European Standard for sports surfaces for outdoor areas, ensuring performance and safety.

These certifications are independently verified, providing objective assurance of our product's quality, safety, and environmental responsibility.

Lead Time & Fulfillment:

Our streamlined manufacturing and logistics ensure efficient project execution. Typical lead times for standard court systems range from 4-6 weeks from order confirmation to dispatch, with larger or highly customized projects requiring slightly longer. We maintain robust supply chain management to minimize delays and provide accurate delivery estimates.

Warranty Commitments:

We offer an industry-leading 10-15 year limited manufacturer's warranty on our modular sports tiles, covering defects in material and workmanship. This extensive warranty period reflects our confidence in the durability and longevity of our products under normal use and proper maintenance. Specific terms and conditions are provided with each quotation.

Dedicated Customer Support & After-Sales Service:

Our commitment extends beyond installation. We provide comprehensive after-sales support, including:

- Technical assistance for maintenance and minor repairs.

- Availability of replacement parts/tiles.

- Guidance on cleaning protocols and seasonal care.

- Dedicated account managers for ongoing client relationships.

Our goal is to ensure your investment continues to perform optimally for decades.

Figure 3: Quality assurance and product testing for certified performance.

Frequently Asked Questions (FAQ)

Q1: What types of sports can be played on an outdoor multipurpose outdoor sports court?

A1: Our courts are designed for a wide range of sports, including basketball, tennis, volleyball, badminton, futsal, pickleball, and roller sports. The modular nature allows for custom line markings to accommodate multiple sports simultaneously or adapt to specific needs.

Q2: What is the required sub-base for installation?

A2: The modular tiles can be installed over any reasonably flat, hard surface. This includes existing concrete or asphalt courts, or a newly prepared compacted aggregate base. The surface must be stable, level, and offer adequate drainage for the sub-base itself.

Q3: How durable are the colors in outdoor conditions?

A3: Our tiles are manufactured with UV stabilizers embedded in the virgin polypropylene material. This ensures exceptional resistance to fading, chalking, and degradation from prolonged sun exposure, maintaining vibrant colors for many years, significantly outperforming painted surfaces.

Q4: What is the typical maintenance routine for these courts?

A4: Maintenance is minimal. Routine cleaning involves sweeping debris, leaves, or dirt. For a deeper clean, the court can be hosed down with water. Unlike traditional courts, no periodic resurfacing, crack filling, or extensive repainting is required. Individual damaged tiles can be easily replaced.

Q5: Are these courts suitable for extreme weather conditions, including freezing temperatures?

A5: Yes, our modular interlocking tile systems are designed to withstand a wide range of temperatures, typically from -30°C to +70°C. The flexible, interlocking design accommodates thermal expansion and contraction, preventing cracking and warping that are common with rigid surfaces in freeze-thaw cycles. The self-draining feature also prevents ice accumulation.

Conclusion: The Strategic Choice for Modern Sports Infrastructure

The strategic investment in a high-performance outdoor multipurpose outdoor sports court represents a forward-thinking decision for any B2B entity seeking durable, versatile, and cost-effective athletic infrastructure. By combining advanced material science, precision engineering, and a focus on player safety and environmental responsibility, our modular sports courts deliver unparalleled value. From rapid installation and minimal maintenance to exceptional longevity and adaptable functionality, these courts provide a superior total cost of ownership and an enhanced user experience.

As demand for dynamic and sustainable recreational spaces continues to grow, our commitment to innovation and client satisfaction positions us as the trusted partner for transforming outdoor areas into vibrant, multi-functional sports arenas. We empower municipalities, educational institutions, and private developers to build communities, foster health, and unlock the full potential of their outdoor spaces.

References

- Grand View Research. (2023). Sports Flooring Market Size, Share & Trends Analysis Report By Material, By Application, By Region, And Segment Forecasts, 2020 - 2027.

- ASTM International. (2011). F2769-11: Standard Specification for Indoor and Outdoor Sport Surfacing.

- European Committee for Standardization. (2019). EN 14877: Sports surfaces for outdoor areas — Specification for synthetic surfaces for outdoor sports areas — Requirements.

- International Organization for Standardization. (2015). ISO 9001: Quality management systems — Requirements.

- Plastics Technology. (2022). Polypropylene (PP): Properties, Processing, and Applications.

-

Durable Volleyball Ground Mats for Safe & Competitive Play

NewsNov.24,2025

-

Premium Volleyball Court Mat: Safety, Durability & Performance for Global Play

NewsNov.23,2025

-

Durable and Eco-Friendly Rubber Play Mats Outdoor for Safer Playgrounds

NewsNov.22,2025

-

Comprehensive Guide to Types of Interlock Tiles: Materials, Uses & Trends

NewsNov.22,2025

-

Exploring Different Types of Interlocking Tiles: Global Uses and Benefits

NewsNov.21,2025

-

PVC Interlocking Floor Tiles Price – Comprehensive Guide for Smart Flooring Choices

NewsNov.20,2025