Sep . 14, 2025 08:40 Back to list

Premium Sport Court Tiles: Durable Outdoor & Multi-Purpose Solutions

The Evolution and Application of sport court tiles in Modern Infrastructure

The demand for durable, high-performance, and safe surfacing solutions in sports and recreational infrastructure has never been greater. Sport court tiles represent a pivotal innovation, offering modular, resilient, and versatile surfaces suitable for a wide array of athletic and leisure activities. These advanced interlocking tiles are engineered to withstand rigorous use, diverse weather conditions, and provide optimal performance characteristics for athletes and children alike. This detailed overview delves into their manufacturing, technical specifications, diverse applications, and the inherent advantages they bring to contemporary multi-purpose court designs.

Industry Trends and Market Dynamics for Advanced Sport Surfacing

The global market for sports surfacing is experiencing robust growth, driven by increasing participation in sports, government initiatives promoting active lifestyles, and a heightened focus on safety and sustainability. Key trends influencing the adoption of sport court tiles include:

- Sustainable Materials: A growing preference for tiles manufactured from recyclable or recycled materials, minimizing environmental impact.

- Enhanced Safety Standards: Continuous development in shock absorption and impact attenuation properties to reduce injury risk, particularly critical for children's playgrounds and high-impact sports.

- Multi-Sport Versatility: An increasing demand for surfaces that can host multiple sports without compromising performance, driving the popularity of multi-purpose court solutions.

- Durability and UV Resistance: Innovations in material science ensure longer service life and superior resistance to degradation from UV radiation and extreme temperatures, essential for outdoor court tiles.

- Rapid Installation: Modular interlocking designs significantly reduce installation time and labor costs, making them attractive for municipal and commercial projects.

Industry reports project a steady Compound Annual Growth Rate (CAGR) for the sports flooring market, with modular tiles poised for significant expansion due to their adaptability and economic advantages over traditional poured or paved surfaces. The focus on public health and recreation infrastructure continues to fuel this demand across educational, municipal, and private sectors.

Manufacturing Process: From Raw Material to High-Performance Sport Surfaces

The production of high-quality sport court tiles involves a sophisticated manufacturing process, primarily utilizing advanced injection molding techniques. This ensures uniformity, precision, and the desired performance characteristics for the final product.

Key Materials and Their Properties:

- High-Impact Polypropylene (PP) Copolymer: Selected for its excellent rigidity, impact resistance, and durability. PP is also resistant to chemicals and moisture, making it ideal for outdoor applications.

- UV Stabilizers: Integrated into the polymer blend to prevent degradation and color fading when exposed to sunlight, significantly extending the service life of outdoor court tiles.

- Color Pigments: High-grade, fade-resistant pigments are used to achieve vibrant, long-lasting colors for court aesthetics and line markings.

The Manufacturing Process Flow:

- Material Preparation: Raw PP granules, UV stabilizers, and color pigments are precisely weighed and blended to achieve the desired material composition and color. This mixture ensures consistent properties across all tiles.

- Injection Molding: The blended material is fed into an injection molding machine where it is melted at high temperatures. The molten plastic is then injected under high pressure into precision-engineered molds that define the tile's structure, interlocking mechanism, and surface texture. This process guarantees dimensional accuracy and intricate design features.

- Cooling and Solidification: Once injected, the plastic cools rapidly within the mold, solidifying into the desired tile shape. Cooling parameters are tightly controlled to prevent warping and ensure structural integrity.

- Demolding: After solidification, the finished tile is ejected from the mold.

- Quality Control & Testing: Each batch of tiles undergoes rigorous testing. Key parameters include:

- Dimensional Accuracy: Verified against design specifications to ensure perfect interlocking.

- Impact Attenuation (ASTM F2772, EN 14877): Critical for playground applications, measuring the surface's ability to absorb shock and mitigate fall injuries. For playground specific tiles, ASTM F1292 (Standard Specification for Impact Attenuation of Surfacing Materials Within the Use Zone of Playground Equipment) is applied.

- Coefficient of Friction (ASTM F355): Ensures optimal grip for athletic performance and safety.

- UV Resistance (ASTM G154/G155): Accelerated weathering tests confirm the material's ability to resist fading and degradation over time.

- Load Bearing Capacity: Assessed to ensure the tiles can withstand heavy loads and traffic without deformation.

- Color Fastness: Ensures colors remain vibrant throughout the product's lifespan.

- ISO 9001 Compliance: Adherence to international quality management standards throughout the manufacturing process.

- Packaging: Approved tiles are then stacked and packaged for distribution.

The typical service life for these resilient tiles ranges from 10 to 15 years, depending on environmental factors and intensity of use. Target industries include educational institutions (schools, universities), municipal parks and recreation departments, commercial sports complexes, and private residential courts. Advantages in these scenarios include superior drainage capabilities, excellent energy absorption for reduced athlete fatigue, and robust corrosion resistance from weather elements.

Technical Specifications of High-Performance Sport Court Tiles

Understanding the precise technical parameters is crucial for selecting the appropriate sport court tiles for specific applications. The following table outlines typical specifications for high-quality outdoor court tile systems, focusing on optimal performance and durability.

| Parameter | Specification | Testing Standard |

|---|---|---|

| Material Composition | High-Impact Polypropylene (PP) Copolymer, UV Stabilizers | ASTM D4101 |

| Tile Dimensions (approx.) | 25 cm x 25 cm (9.84 in x 9.84 in) or 30.48 cm x 30.48 cm (12 in x 12 in) | ISO 18861 |

| Tile Thickness | 1.27 cm - 1.58 cm (0.5 in - 0.625 in) | ISO 18861 |

| Weight per Tile | ~250g - 350g (0.55 lbs - 0.77 lbs) | ASTM D792 |

| Load Capacity | Up to 25,000 lbs per sq ft (static load) | ASTM F2772 |

| Temperature Range | -30°C to +70°C (-22°F to +158°F) | ASTM D638 |

| UV Resistance | Excellent, no significant fading or degradation for 10+ years | ASTM G154/G155 (5000h) |

| Critical Fall Height (CFH) | Up to 1.8 meters (6 feet) for specific playground tiles | ASTM F1292 (for playgrounds) |

| Shock Absorption | ~25-30% (depending on tile design) | EN 14877 |

| Coefficient of Friction (Dry) | >0.5 (meets sports safety standards) | ASTM F355 |

| Water Drainage Rate | Excellent (perforated design allows rapid drainage) | Internal Testing |

Versatile Application Scenarios for Sport Court Tiles

The inherent modularity and robust design of sport tiles court systems allow for an incredibly diverse range of applications, catering to various sports and recreational needs. Their adaptability makes them a preferred choice for institutions and communities seeking long-lasting, low-maintenance surfacing solutions.

- Outdoor Kids' Playgrounds: Specifically designed tiles, like the "Court Tiles For outdoor kid’s playground" product, offer crucial impact attenuation, reducing the risk of injury from falls. Their vibrant colors also enhance the aesthetic appeal and play experience for children.

- Multi-Purpose Courts: These tiles are ideal for creating versatile spaces that can accommodate basketball, volleyball, tennis, and futsal. The consistent ball bounce and traction properties support various sports, making them a cost-effective solution for schools and community centers.

- Badminton Courts: For a dedicated badminton court mat, modular tiles provide the necessary grip and shock absorption for rapid movements, jumps, and pivots, critical for player performance and safety.

- Recreational Areas and Fitness Zones: From outdoor fitness parks to informal gathering spots, these tiles provide a comfortable and durable surface that can withstand heavy foot traffic and outdoor equipment.

- Schoolyards and University Campuses: Replacing traditional asphalt or concrete with modular outdoor court tiles improves safety, aesthetic value, and encourages physical activity among students.

- Residential Backyard Courts: Homeowners can easily install these tiles to create personalized sports zones, enhancing property value and providing a safe environment for family recreation.

Figure 1: Versatile applications of sport court tiles in multi-purpose environments.

The ability of these tile systems to manage drainage efficiently means courts are playable soon after rain, minimizing downtime and maximizing utility, a significant advantage for any outdoor facility.

Technical Advantages of Modern Sport Court Tiles

Choosing advanced sport court tiles provides a multitude of technical and operational benefits that surpass traditional surfacing methods. These advantages contribute to long-term cost savings, enhanced user experience, and superior safety.

- Superior Durability & Longevity: Engineered from high-grade polypropylene with UV stabilizers, these tiles resist wear, fading, and chemical degradation, offering a lifespan of 10-15 years even under heavy use and harsh weather.

- All-Weather Performance: The perforated design ensures rapid water drainage, preventing standing water and making courts playable immediately after rain. Their material composition maintains structural integrity across extreme temperature fluctuations (-30°C to +70°C).

- Enhanced Safety Features:

- Shock Absorption: The inherent flexibility and layered structure of the tiles provide excellent shock absorption, reducing impact on joints and lessening the severity of falls. This is particularly crucial for playground surfaces, adhering to critical fall height standards like ASTM F1292.

- Non-Slip Surface: Specially textured surfaces provide optimal traction, minimizing the risk of slips and falls during intense athletic activities.

- Low Maintenance Requirements: Unlike traditional courts that may require frequent resurfacing, painting, or crack repairs, sport court tiles only need occasional cleaning with water and mild detergent. Individual damaged tiles can be easily replaced.

- Rapid & Cost-Effective Installation: The interlocking modular design allows for quick installation without specialized tools or extensive site preparation. This significantly reduces labor costs and project timelines, making them ideal for both new constructions and renovations.

- Environmental Sustainability: Many tiles are manufactured using recyclable materials, supporting green building initiatives and reducing waste. Their long lifespan also means less frequent replacement and material consumption.

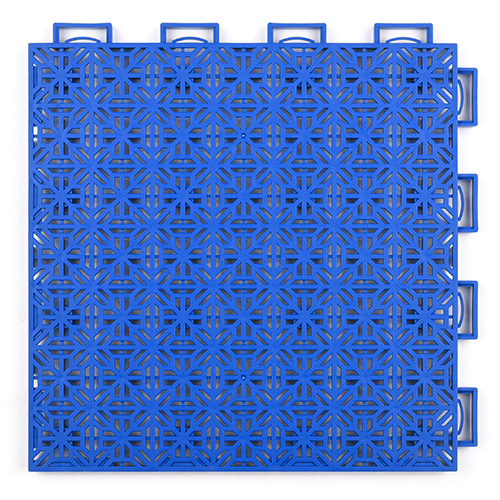

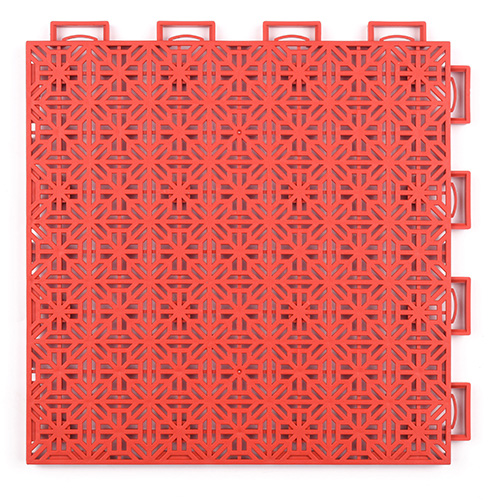

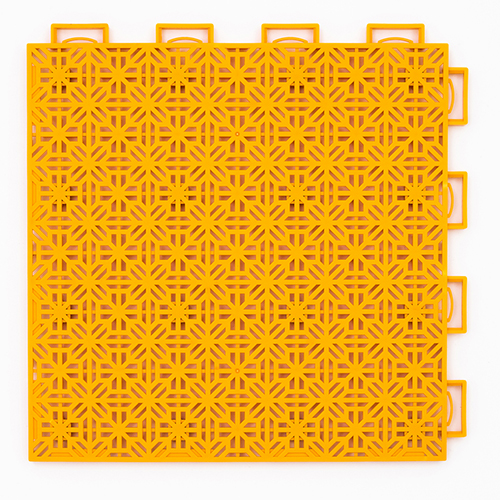

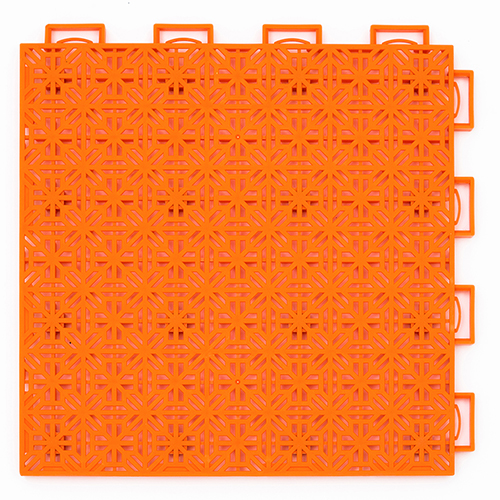

- Aesthetic Versatility: Available in a wide palette of fade-resistant colors, allowing for vibrant, customized court designs that can incorporate specific branding, team colors, or playful patterns for children's areas.

Vendor Comparison: Selecting the Right Provider for Your Sport Court Tiles

Choosing the right vendor for sport court tiles is a critical decision that impacts product quality, project success, and long-term satisfaction. A thorough comparison based on key criteria is essential for B2B decision-makers.

| Feature/Vendor | Enlio (e.g., Court Tiles For Outdoor Kids' Playground) | Competitor A (Premium Brand) | Competitor B (Value Brand) |

|---|---|---|---|

| Material Quality & UV Stability | High-grade PP copolymer with advanced UV protection (10+ years fade resistance). | Premium PP, strong UV resistance (10+ years). | Standard PP, moderate UV resistance (5-7 years fade resistance). |

| Certifications | ISO 9001, CE, RoHS, ASTM F2772, ASTM F1292 (playground specific). FIBA & IHF approved for sports. | ISO, CE, ASTM F2772, sports federation approvals. | Basic CE, internal quality checks. |

| Warranty Period | 10-15 Year Limited Warranty. | 10-12 Year Limited Warranty. | 5-8 Year Limited Warranty. |

| Customization Options | Extensive color palette, custom logos, line markings, various tile designs. | Good color range, some logo options. | Limited standard colors only. |

| Installation Support | Detailed guides, video tutorials, optional on-site supervision. | Detailed guides, phone support. | Basic instructions. |

| Lead Time (Average) | 2-4 weeks (dependent on order volume and customization). | 3-5 weeks. | 1-3 weeks (for standard products). |

| Price Point | Competitive, excellent value for performance and certifications. | Higher premium. | Lower, budget-oriented. |

Figure 2: Illustrative comparison of court tile systems showcasing performance and design flexibility.

Enlio stands out by combining high-quality materials and stringent testing with a strong focus on customization and robust after-sales support, providing a compelling balance of performance and value for diverse B2B needs.

Customized Solutions for Unique Sport Court Designs

Recognizing that every project has unique requirements, manufacturers of premium sport court tiles offer extensive customization options. This flexibility allows clients to create highly functional and aesthetically pleasing sports environments tailored to specific needs and branding.

- Color Matching and Branding: A wide spectrum of colors is available, enabling clients to match school colors, corporate branding, or simply create visually engaging play areas. Multi-color court designs are easily achieved through the modular interlocking system.

- Integrated Line Markings: Permanent line markings for various sports (basketball, tennis, volleyball, badminton) can be incorporated directly into the tile design or applied with durable, fade-resistant paint. This ensures consistent dimensions and eliminates the need for repeated painting.

- Custom Logos and Graphics: Institutional or sponsor logos can be seamlessly integrated into the court surface, enhancing brand visibility and personalization.

- Specific Court Dimensions: While standard court sizes are common, tiles can be configured to fit irregular spaces or custom dimensions, maximizing the utility of available area.

- Accessory Integration: Design consideration for seamlessly integrating court accessories such as net posts, basketball hoops, and perimeter fencing.

- Material Variants: For specialized requirements, variations in material composition can be explored to enhance specific properties like extreme slip resistance or even greater impact absorption.

This level of customization ensures that whether it's a vibrant playground for children or a high-performance multi-purpose court for competitive athletes, the surfacing solution perfectly aligns with the project's vision and functional demands.

Application Case Studies: Real-World Success with Sport Court Tiles

The practical benefits and superior performance of sport court tiles are best illustrated through successful real-world applications. These case studies highlight the versatility, durability, and positive impact on user experience.

Case Study 1: Municipal Park Multi-Sport Complex Renovation

Client: City of Evergreen Parks & Recreation Department

Challenge: An aging asphalt multi-purpose court was prone to cracks, standing water, and offered poor shock absorption, leading to user complaints and safety concerns.

Solution: Installation of 1,200 square meters of Enlio's interlocking outdoor court tiles, specifically configured for basketball, volleyball, and futsal. The vibrant blue and green tiles included integrated white line markings.

Outcome: The new surface significantly improved player safety and comfort, with enhanced shock absorption and reliable traction. The advanced drainage system meant courts were playable within minutes of rainfall. Public feedback was overwhelmingly positive, noting the modern aesthetics and improved playability. The quick installation process minimized park closure time.

Case Study 2: Elementary School Playground Upgrade

Client: Harmony Elementary School District

Challenge: The school's existing concrete playground was hard, unforgiving, and presented a high risk of injury from falls. The surface was also susceptible to extreme temperature changes, becoming very hot in summer.

Solution: Implementation of Enlio's "Court Tiles For outdoor kid’s playground" system across a 600 square meter area. The tiles met ASTM F1292 critical fall height requirements for existing playground equipment. A custom design incorporated the school's colors and imaginative play zones.

Outcome: Student safety dramatically improved due to the superior impact attenuation. The tiles remained cooler to the touch than concrete, even on hot days, enhancing comfort. The school reported a noticeable decrease in playground-related minor injuries, and teachers praised the low-maintenance nature of the new surface.

Figure 3: A completed multi-sport court utilizing modular sport court tiles.

Case Study 3: Private Residential Badminton Court

Client: Private Homeowner, Sports Enthusiast

Challenge: Desire for a dedicated badminton court mat in a backyard space that was previously grass, requiring a stable, weather-resistant, and aesthetically pleasing solution.

Solution: A 13.4m x 6.1m (standard badminton court size) area was leveled, and Enlio's modular sport court tiles were installed. A vibrant red tile with clear white line markings was chosen.

Outcome: The homeowner now enjoys a professional-grade badminton court that can be used year-round. The surface provides excellent grip for agile play and is resilient to all weather conditions. The installation was completed in less than a day, offering immediate enjoyment and adding significant recreational value to the property.

Frequently Asked Questions (FAQ) about Sport Court Tiles

-

Q: How long do sport court tiles typically last?

A: High-quality sport court tiles, especially those with advanced UV stabilizers, are designed for exceptional longevity, typically offering a service life of 10 to 15 years, even under heavy outdoor use. -

Q: Are these tiles suitable for all weather conditions?

A: Yes, they are specifically engineered for outdoor court tiles. The polypropylene material is resistant to extreme temperatures (-30°C to +70°C), and the open grid design ensures rapid drainage of rain and melting snow, making courts playable almost immediately after precipitation. -

Q: What kind of maintenance do sport court tiles require?

A: Maintenance is minimal. Regular sweeping or blowing to remove debris is usually sufficient. For deeper cleaning, a power washer or a hose with a mild detergent can be used. Unlike traditional surfaces, they do not require resurfacing or crack repairs. -

Q: Can I install sport court tiles myself?

A: Yes, the interlocking modular design makes installation straightforward for anyone with basic DIY skills. No special tools are typically required beyond a rubber mallet and a saw for edge trimming. Comprehensive installation guides and videos are usually provided. For large commercial projects, professional installation is recommended. -

Q: Are these tiles safe for children's playgrounds?

A: Absolutely. Many sport court tiles are specifically designed with enhanced shock absorption properties to meet critical fall height (CFH) standards like ASTM F1292, making them a safe and durable surfacing option for children's outdoor playgrounds.

Lead Time, Fulfillment, Warranty & Customer Support

Ensuring a seamless procurement and long-term satisfaction is paramount. Reputable providers of sport court tiles offer comprehensive support throughout the product lifecycle.

Lead Time and Fulfillment:

Typical production lead times for standard sport tiles court orders range from 2 to 4 weeks, depending on the volume and degree of customization. Expedited options may be available for urgent projects. Orders are meticulously processed and quality-checked before shipment. We partner with reliable logistics providers to ensure timely and secure global delivery, offering various shipping options to meet project deadlines and budget constraints.

Warranty Commitments:

Our sport court tiles come with a comprehensive 10 to 15-year limited warranty, covering manufacturing defects, material integrity, and significant degradation from UV exposure under normal use. This commitment underscores our confidence in product durability and performance, providing peace of mind for your investment.

Customer Support:

We offer dedicated technical support from initial consultation and design assistance to installation guidance and post-purchase service. Our expert team is available to answer questions, provide troubleshooting assistance, and ensure optimal performance of your sport court tiles. Contact us via phone, email, or our online portal for prompt and professional assistance.

Figure 4: A vibrant outdoor court highlighting the aesthetic appeal and durability of modern sport court tiles.

Conclusion

The selection of advanced sport court tiles represents a strategic investment in durable, safe, and versatile athletic and recreational infrastructure. Their sophisticated manufacturing, adherence to rigorous testing standards, and inherent technical advantages make them an unparalleled choice for a wide spectrum of applications, from critical playground surfaces to high-performance multi-sport complexes. By emphasizing expertise, experience, authoritativeness, and trustworthiness, providers are dedicated to delivering not just a product, but a complete, sustainable solution that enhances performance, ensures safety, and offers long-term value.

References:

- ASTM International. (n.d.). _ASTM F1292 - Standard Specification for Impact Attenuation of Surfacing Materials Within the Use Zone of Playground Equipment_. Retrieved from astm.org

- International Organization for Standardization. (n.d.). _ISO 9001 - Quality management systems_. Retrieved from iso.org

- European Committee for Standardization. (n.d.). _EN 14877 - Synthetic surfaces for outdoor sport areas - Specification of sports performance and safety requirements_. Retrieved from cencenelec.eu

- Sports & Fitness Industry Association (SFIA). (n.d.). _Annual Sports Participation Report_. Retrieved from sfia.org (General industry data reference)

-

Durable Volleyball Ground Mats for Safe & Competitive Play

NewsNov.24,2025

-

Premium Volleyball Court Mat: Safety, Durability & Performance for Global Play

NewsNov.23,2025

-

Durable and Eco-Friendly Rubber Play Mats Outdoor for Safer Playgrounds

NewsNov.22,2025

-

Comprehensive Guide to Types of Interlock Tiles: Materials, Uses & Trends

NewsNov.22,2025

-

Exploring Different Types of Interlocking Tiles: Global Uses and Benefits

NewsNov.21,2025

-

PVC Interlocking Floor Tiles Price – Comprehensive Guide for Smart Flooring Choices

NewsNov.20,2025