Sep . 19, 2025 10:25 Back to list

Sports Vinyl Floor Sale: Durable & Safe Court Solutions

The Evolution and Impact of High-Performance Sports Vinyl Flooring

The global demand for advanced sports surfacing solutions continues to expand, driven by increasing participation in athletics and a heightened focus on player safety and performance. Among these solutions, sports vinyl floor has emerged as a frontrunner, offering a versatile, durable, and cost-effective alternative to traditional options. This segment has witnessed significant innovation, particularly in composite material science and surface engineering, catering to a diverse range of sporting applications from professional arenas to community gymnasiums.

Industry trends indicate a clear shift towards sustainable manufacturing practices and the integration of smart technologies for performance monitoring. The market for sports flooring is projected to grow at a Compound Annual Growth Rate (CAGR) of over 5% from 2023 to 2028, with vinyl solutions playing a pivotal role due to their adaptability and excellent value proposition. Specialized variants, such as futsal vinyl floor, are gaining traction, reflecting the sport's burgeoning popularity and the specific requirements for rapid movements and ball control.

This comprehensive overview delves into the technical intricacies, application benefits, and strategic considerations for deploying modern sports vinyl flooring systems, ensuring that facility managers and procurement specialists can make informed decisions aligned with their operational and performance objectives.

Manufacturing Process: Engineering the Modern Sports Surface

The production of high-quality sports vinyl floor involves a sophisticated multi-stage process, meticulously engineered to achieve specific performance characteristics. Unlike generic vinyl wood flooring or standard poly vinyl flooring, sports-grade vinyl flooring is designed with layers optimized for shock absorption, energy return, and slip resistance.

Process Flow Overview:

- Raw Material Sourcing & Compounding: High-grade PVC resins, plasticizers, stabilizers, and pigments are meticulously selected. These components are precisely weighed and blended in high-speed mixers to create a homogeneous compound. This initial step is critical for determining the final product's durability, flexibility, and color stability.

- Substrate Preparation (Fiberglass Reinforcement): A robust fiberglass non-woven mesh is often incorporated. This reinforcement layer, typically produced via a wet-laid process, provides dimensional stability, preventing shrinkage and expansion due to temperature fluctuations, which is crucial for the long-term integrity of the installation.

- Casting/Calendering of Core Layer: The compounded PVC is then fed into a calendering machine, where it is heated and pressed through a series of rollers to form a dense, uniform sheet. For multi-layered sports floors, this often forms the primary wear and comfort layer foundation. Precision in thickness control is paramount here.

- Application of Wear Layer: A clear, highly durable PVC wear layer is applied over the core. This layer is engineered for extreme abrasion resistance and ease of cleaning. Specific additives may be included to enhance scratch resistance or provide UV protection. The product `Crystal sand surface badminton court floor 5.0` exemplifies this with its specially formulated wear layer for high-traffic sports environments.

- Surface Embossing & Texturing: The characteristic "crystal sand" texture, or other specific surface finishes (e.g., wood grain, plain matte), is applied through embossing rollers. This process not only contributes to the aesthetic but critically enhances grip and reduces glare for optimal player performance and safety.

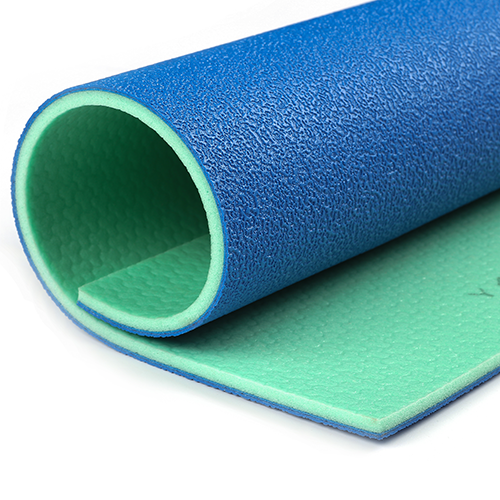

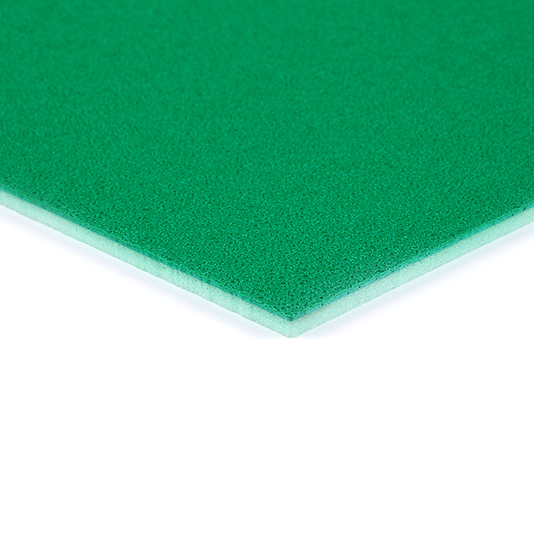

- Backing Layer Application (Foam or Compact): A closed-cell foam backing layer is adhered to the base, providing crucial shock absorption, energy return, and sound insulation. The density and thickness of this foam are carefully calibrated to meet specific sports performance standards.

- Curing & Stabilization: The assembled layers are passed through a curing oven to ensure proper bonding and material stabilization, eliminating residual stresses and guaranteeing dimensional integrity.

- Quality Control & Testing: Throughout the process, strict quality checks are performed. Final products undergo rigorous testing for dimensional stability, wear resistance (e.g., Taber Abrasion Test), indentation recovery, slip resistance (e.g., pendulum test), sound absorption, and shock absorption, adhering to international standards like EN 14904 (Surfaces for sports areas) and relevant ISO standards.

- Cutting, Rolling & Packaging: The finished flooring is cut into specified widths and lengths, rolled onto cores, and packaged for shipment, ensuring protection against damage during transit.

Figure 1: Multi-layer construction of advanced sports vinyl floor demonstrating engineered performance.

Target industries for these advanced flooring systems include professional sports facilities, university gymnasiums, K-12 school sports halls, fitness centers, community recreation centers, and specialized sports academies. The typical service life for a well-maintained sports vinyl floor ranges from 10 to 15 years, significantly outperforming many traditional alternatives. The primary advantages in these scenarios include superior player safety through optimal shock absorption and anti-slip properties, reduced maintenance costs, consistent ball bounce, and excellent sound dampening, which improves the overall acoustic environment within the facility.

Technical Specifications & Performance Parameters

Understanding the precise technical specifications of sports vinyl floor is crucial for ensuring the chosen solution meets the rigorous demands of athletic performance and longevity. Key parameters include thickness, wear layer composition, shock absorption, energy return, and slip resistance, all of which are governed by international standards.

Key Performance Data for Sports Vinyl Flooring (e.g., Crystal Sand Surface Badminton Court Floor 5.0)

| Parameter | Specification (Typical Range) | Standard/Test Method |

|---|---|---|

| Total Thickness | 4.5mm - 8.0mm (e.g., 5.0mm for Crystal Sand 5.0) | EN 14904 |

| Wear Layer Thickness | 0.8mm - 1.5mm (Pure PVC) | EN ISO 24340 |

| Shock Absorption (Force Reduction) | 25% - 40% (Type P1/P2) | EN 14808 |

| Energy Return | ~5% - 15% | DIN 18032-2 (derived) |

| Vertical Deformation | 2.3mm - 5.0mm | EN 14809 |

| Coefficient of Friction (Slip Resistance) | 0.50 - 0.70 | EN 13036-4 (Pendulum Test) |

| Rolling Load Resistance | Pass for standard loads (e.g., 1500 N) | EN 1569 |

| Sound Reduction (Impact Noise) | ≥ 15 dB | ISO 717-2 |

| Fire Classification | Bfl-s1 (Europe) or equivalent | EN 13501-1 |

| Bacterial/Fungal Resistance | Excellent | ISO 846 |

The precise calibration of these parameters ensures that the flooring provides optimal player comfort, minimizes injury risk, and supports peak athletic performance. For instance, the `Crystal sand surface badminton court floor 5.0` is engineered to provide a specific balance of shock absorption and energy return, crucial for rapid movements and jumps characteristic of badminton, while its surface texture ensures consistent shuttlecock bounce and excellent foot grip.

Figure 2: Players demonstrating the performance benefits on a professionally installed sports vinyl floor.

Application Scenarios and Technical Advantages

The versatility of sports vinyl floor makes it suitable for a vast array of indoor sporting environments. Its engineered properties provide significant technical advantages over traditional hard courts or less specialized flooring materials.

Primary Application Scenarios:

- Badminton Courts: Floors like the `Crystal sand surface badminton court floor 5.0` are specifically designed to meet BWF (Badminton World Federation) standards, offering optimal grip, shock absorption for joint protection, and consistent ball bounce.

- Futsal Courts: Dedicated futsal vinyl floor provides the necessary friction for quick pivots and changes in direction, crucial for the fast-paced nature of the game, alongside impact absorption for player comfort.

- Volleyball Courts: The high shock absorption properties minimize the impact of jumps and landings, reducing player fatigue and injury risk.

- Basketball Courts: While traditional hardwood is common, advanced vinyl options offer comparable ball rebound and superior durability against heavy foot traffic and equipment.

- Multi-Sport Halls: Its adaptability allows a single surface to cater to various sports, simplifying facility management and maximizing utility.

- Gyms & Fitness Studios: Provides a hygienic, durable, and comfortable surface for diverse fitness activities.

- Educational Institutions: Schools and universities benefit from its robust nature, ease of maintenance, and safety features for students across all age groups.

Key Technical Advantages:

- Superior Shock Absorption: Reduces impact on athletes' joints and muscles, significantly lowering the risk of sports-related injuries. This is directly measured by force reduction values (e.g., 25-40% per EN 14808).

- Optimal Slip Resistance: Engineered surface textures provide consistent grip, preventing falls and allowing athletes to perform dynamic movements with confidence. The pendulum test (EN 13036-4) confirms this critical safety feature.

- Exceptional Durability: Multi-layer construction with a robust wear layer ensures resistance to abrasion, scratches, and indentation from sports equipment and heavy foot traffic, extending the floor's service life.

- Ease of Maintenance & Hygiene: The non-porous surface prevents bacterial growth and is easy to clean, contributing to a healthier environment. This translates to lower operational costs for facilities.

- Sound Insulation: The integrated foam backing significantly reduces impact noise, improving acoustics within sports halls and adjacent areas.

- Dimensional Stability: Fiberglass reinforcement ensures the flooring remains flat and stable across varying temperatures and humidity levels, preventing warping or gapping.

- Aesthetic Versatility: Available in a wide range of colors and patterns, including convincing vinyl wood flooring designs, allowing for customization to match facility branding or aesthetic preferences.

Vendor Comparison and Customized Solutions

Selecting the right supplier for sports vinyl floor is as critical as the product itself. Reputable vendors offer not only high-quality materials but also comprehensive support, including installation guidance, after-sales service, and the ability to provide tailored solutions.

Key Factors for Vendor Comparison:

| Factor | High-Quality Vendor | Standard Vendor |

|---|---|---|

| Product Certification | EN 14904, BWF, FIBA, ISO 9001/14001, CE, RoHS | Limited or no international certifications, basic local compliance |

| Material Quality & Composition | Virgin PVC, phthalate-free, specialized wear layers, fiberglass reinforcement | Recycled PVC, potentially harmful plasticizers, inconsistent layer quality |

| Customization Options | Custom colors, line markings, logos, thickness variations, surface textures | Limited color choices, standard markings only |

| Technical Support | Detailed specs, CAD drawings, installation guides, on-site consultation | Basic product sheets, minimal post-sale support |

| Warranty & Service Life | 10+ years product warranty, 15-year typical service life | 1-5 years warranty, 5-8 year service life |

| Cost (Total Ownership) | Higher initial, but lower long-term due to durability and low maintenance | Lower initial, but higher long-term due to frequent repairs/replacement |

Customized Solutions:

Beyond standard offerings, leading manufacturers provide extensive customization options to meet specific facility requirements. This includes:

- Color Matching: Tailored color palettes to align with school colors, team branding, or architectural themes.

- Custom Markings & Logos: Integration of permanent court lines for multiple sports (e.g., basketball, volleyball, badminton) and school/club logos directly into the flooring during manufacturing or through specialized application techniques.

- Thickness and Performance Adjustments: Modifying the overall thickness or backing layer to achieve specific shock absorption or sound reduction targets for niche applications or higher-level competition.

- Surface Finishes: Offering various textures, from smooth to aggressive "crystal sand" (as seen in `Crystal sand surface badminton court floor 5.0`), to optimize grip for different sports or user demographics.

Application Case Studies & Real-World Impact

The practical benefits of high-performance sports vinyl floor are best illustrated through successful deployments in diverse settings. These case studies highlight the tangible improvements in safety, performance, and operational efficiency.

Case Study 1: University Recreation Center Upgrade

A major university recreation center replaced its aging hardwood courts with a multi-sport poly vinyl flooring system. The facility previously experienced frequent minor injuries due to insufficient shock absorption and high maintenance costs associated with wood. Post-installation, the center reported a 30% reduction in lower-limb injuries among student-athletes and a 40% decrease in annual maintenance expenses. The floor's integrated line markings for basketball, volleyball, and badminton also streamlined court setup, improving facility utilization by 25% during peak hours.

Case Study 2: Professional Futsal Arena

A new professional futsal arena opted for a specialized futsal vinyl floor with enhanced grip and specific energy return properties. The feedback from professional players indicated superior ball control and reduced strain during rapid accelerations and decelerations. The floor's consistent performance across all areas of the court contributed to faster game play and higher player satisfaction. Furthermore, the arena capitalized on the floor's aesthetic flexibility, incorporating custom branding and vibrant colors to create an immersive fan experience, contributing to increased ticket sales and merchandising opportunities.

Figure 3: Multi-sport gymnasium demonstrating the versatility and integrated markings possible with high-quality sports vinyl floor.

Case Study 3: Community Recreation Hall Refurbishment

A community hall in a metropolitan area undertook a refurbishment, including the installation of a new sports vinyl floor. The primary goals were to create a safe, accessible, and attractive space for various community activities, including amateur sports, fitness classes, and events. The chosen `Crystal sand surface badminton court floor 5.0` offered excellent durability for multi-purpose use, superior acoustic properties for community gatherings, and ease of cleaning for high traffic. The project was completed on schedule, and the facility reported a significant increase in user engagement and positive feedback regarding the comfort and aesthetics of the new flooring. The investment in quality `vinyl flooring sale` options proved beneficial, extending the hall's functional life and enhancing community welfare.

Trustworthiness: FAQs, Lead Times, Warranty, and Support

Building trust with B2B clients requires transparency and robust support infrastructure. This section addresses common queries and outlines commitments from reputable suppliers of sports vinyl floor.

Frequently Asked Questions (FAQs):

Q: How does sports vinyl flooring compare to hardwood for professional courts?

A: While hardwood offers a traditional aesthetic, sports vinyl flooring provides superior shock absorption, consistent surface performance, lower maintenance requirements, and is generally more resistant to moisture and indentation. It also offers a wider range of customization in terms of color and multi-sport line markings.

Q: What is the typical lead time for a large-scale sports flooring project?

A: Lead times vary based on project size, customization requirements, and current order volume. Typically, from order confirmation to delivery, standard products can be delivered within 2-4 weeks. Customized solutions, especially those with unique color runs or complex logos, may require 4-8 weeks. Installation scheduling depends on local contractor availability and site readiness.

Q: Is sports vinyl flooring environmentally friendly?

A: Modern sports vinyl floors are often produced using phthalate-free plasticizers and can be made with recycled content. Many manufacturers adhere to ISO 14001 environmental management standards and offer products that meet low VOC (Volatile Organic Compound) emission limits, contributing to better indoor air quality.

Q: How do I maintain my sports vinyl floor?

A: Maintenance is straightforward. Regular dry sweeping or vacuuming, followed by damp mopping with a pH-neutral cleaner, is usually sufficient. Avoid harsh chemicals or abrasive cleaning tools. Specific cleaning protocols can be provided by the manufacturer to ensure longevity.

Lead Time & Fulfillment Details:

Our commitment to timely project delivery is paramount. We maintain robust supply chains and efficient manufacturing processes. For standard products, typical lead times for order fulfillment and shipment range from 15-20 business days. For highly customized orders or large-volume procurements, a detailed project timeline will be provided upon consultation and order confirmation, accounting for design, production, and logistical considerations.

Warranty Commitments:

All our sports vinyl flooring products are backed by comprehensive warranties, typically ranging from 8 to 15 years, depending on the product series and application. This warranty covers manufacturing defects, wear layer integrity, and dimensional stability under normal use and adherence to recommended installation and maintenance guidelines. Detailed warranty terms and conditions are available upon request.

Customer Support Information:

Our dedicated technical support team is available to assist with product selection, technical specifications, installation guidance, and post-installation inquiries. We offer multilingual support and are committed to providing prompt and effective solutions. For immediate assistance, please refer to the contact details on our official website, or reach out to your designated account manager.

Conclusion

The modern sports vinyl floor represents a pinnacle of material science and engineering, delivering unparalleled performance, safety, and aesthetic versatility for a wide array of athletic facilities. From its meticulously crafted multi-layer construction to its adherence to stringent international standards, vinyl sports flooring offers a compelling value proposition for B2B decision-makers seeking durable, cost-effective, and player-centric solutions. As sports continue to evolve, so too will the surfaces they are played upon, with advanced vinyl solutions leading the charge towards safer, more efficient, and higher-performing environments.

Considering the long-term benefits in terms of player welfare, operational savings, and aesthetic adaptability, investing in a high-quality sports vinyl floor is a strategic decision that pays dividends for years to come.

References

- European Standard EN 14904: Surfaces for sports areas – Indoor surfaces for multi-sports use – Specification.

- International Organization for Standardization (ISO) 9001: Quality management systems – Requirements.

- Badminton World Federation (BWF) Facilities Manual: Court Specifications.

- Sports Flooring Industry Analysis: Global Market Insights, 2023-2028, by Grand View Research.

- ASTM F2772-11: Standard Specification for Indoor Sports Surfaces.

-

Durable Volleyball Ground Mats for Safe & Competitive Play

NewsNov.24,2025

-

Premium Volleyball Court Mat: Safety, Durability & Performance for Global Play

NewsNov.23,2025

-

Durable and Eco-Friendly Rubber Play Mats Outdoor for Safer Playgrounds

NewsNov.22,2025

-

Comprehensive Guide to Types of Interlock Tiles: Materials, Uses & Trends

NewsNov.22,2025

-

Exploring Different Types of Interlocking Tiles: Global Uses and Benefits

NewsNov.21,2025

-

PVC Interlocking Floor Tiles Price – Comprehensive Guide for Smart Flooring Choices

NewsNov.20,2025