Oct . 10, 2025 11:45 Back to list

Vinyl Gym Mat: Non-Slip, Shock-Absorbing, Easy-Clean?

Vinyl Gym Mat Buyer’s Guide: What Pros Look For in Multi‑Layer PVC Sports Flooring

If you’re weighing up a vinyl gym mat for a retrofit or new build, the conversation in 2025 is surprisingly practical: consistent shock absorption, predictable friction, low VOCs, and—because budgets are real—easy upkeep. Enlio’s multi-layer PVC Sports Flooring with gem surface 6.0 has been making the rounds in spec sheets lately. And yes, I’ve seen it down on a few courts; the surface looks like it means business, without demanding a diva-level maintenance routine.

Industry trend check

Gyms are moving from thick rubber to engineered PVC stacks. Why? Repeatable performance. Rubber can be great for weights, but for multi-sport courts, coaches want uniform energy return, safe slip (not too grabby), and decent ball response. Also, venue owners keep asking for “fast installs over concrete” and quiet acoustics. To be honest, the vinyl gym mat category has matured—more testing, fewer gimmicks.

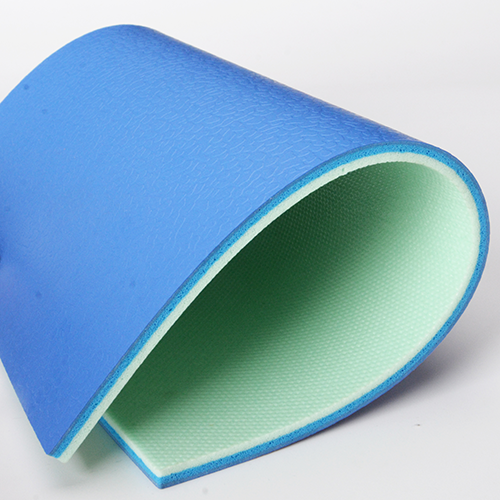

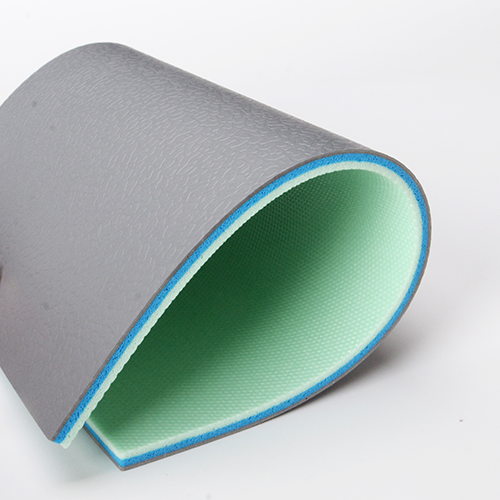

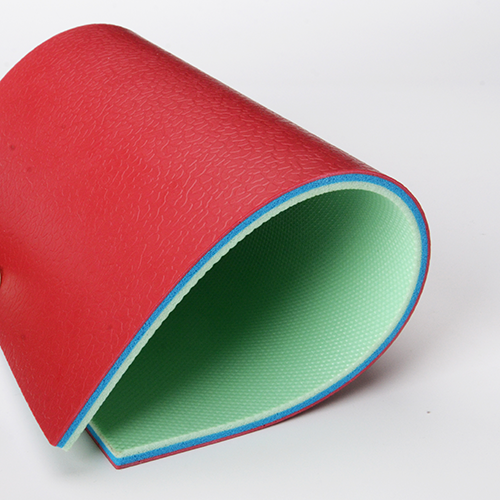

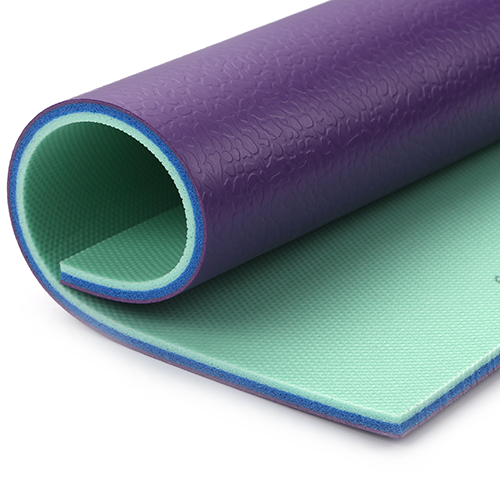

Product snapshot: multi-layer PVC Sports Flooring with gem surface 6.0

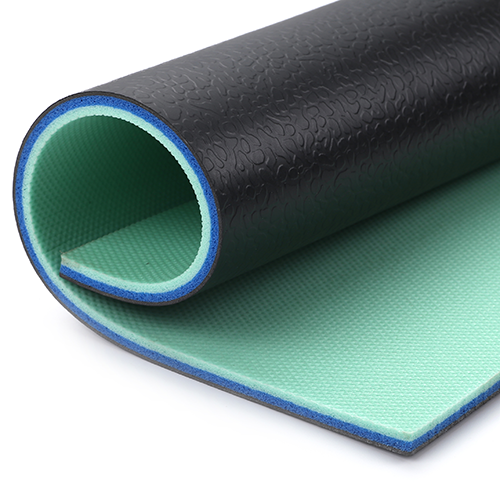

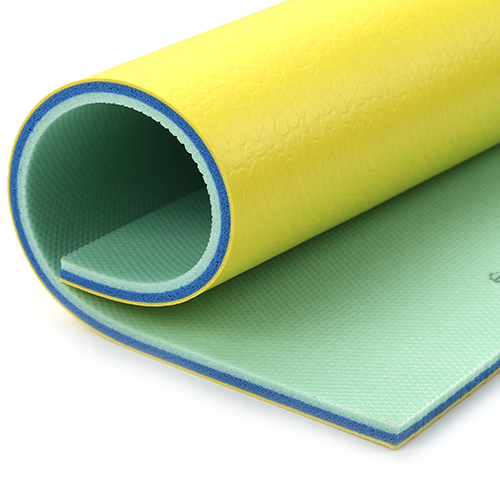

Surface texture matters. The gem surface aims for controlled grip that doesn’t “burn” on slides. Under the hood you’ve got stacked PVC layers, fiberglass reinforcement in many builds like this, and a foamed backing for shock absorption.

| Spec | Multi-layer PVC 6.0 (≈ values) |

|---|---|

| Total thickness | ≈ 6.0 mm |

| Wear layer | ≈ 1.2–1.5 mm transparent PVC |

| Shock absorption (EN 14904) | ≈ 25–35% (P1–P2 band; real-world use may vary) |

| Ball rebound | ≥ 90% (typical lab data) |

| Friction coefficient | μ ≈ 0.4–0.6 (dry) |

| Fire classification | Bfl‑s1 (per EN 13501‑1, product-specific reports recommended) |

| VOC emissions | Low TVOC; ISO 16000 test regime advised |

How it’s made (quick process flow)

Materials: PVC resin + plasticizers (phthalate-free options common), mineral fillers, UV-cured wear layer, glass fiber mesh, foamed PVC backing.

Methods: calendering and lamination, hot-press bonding, surface emboss with gem texture, UV coating.

Testing: EN 14904/ASTM F2772 for sport performance; EN 1516/1517 for ball bounce; ISO 16000 for VOC; ISO 9239‑1 for fire; adhesion/peel and indentation tests.

Service life: around 8–12 years with proper cleaning (auto-scrubber + neutral cleaner), then selective resurfacing or replacement.

Where it fits (and why)

- School and university courts: basketball, volleyball, badminton on one surface.

- Community rec centers: multi-use halls where chairs/tables roll out on weekends.

- Studios: functional training zones that still need some give.

Advantages owners mention: quick tape/weld installs, forgiving maintenance, and the surface “feels predictable.” As one facility manager told me, the vinyl gym mat “just behaves the same in winter and July—less drama.”

Vendor comparison (real-world considerations)

| Option | Performance & Notes |

|---|---|

| Enlio multi-layer PVC 6.0 (gem surface) | Balanced shock absorption/ball response; good line marking; installs over flat concrete; maintenance-friendly. |

| Rubber roll (SBR/EPDM) | Great for weights/acoustics; ball rebound not ideal for court sports; heavier, often pricier per m². |

| EVA foam tiles | Budget-friendly, quick DIY; lower durability, seams can telegraph; not for competitive play. |

Customization, certifications, and origin

Customization: thickness stacks, base foam density, colors, pre-line-marking, and logo inlays are common tweaks. Certifications to look for: EN 14904 or ASTM F2772 compliance, ISO 9001 quality systems, REACH/RoHS materials declarations, and up-to-date fire and VOC reports. Origin for this model: 8th floor, Block B, ICC, No. 95, Cangyu Rd, Yuhua District, Shijiazhuang.

Mini case note

A provincial training gym in Hebei switched to a vinyl gym mat stack like this for a multi-sport hall. After commissioning, staff noted cleaner ball trajectories (fewer “dead zones”) and, anecdotally, fewer slide abrasions. It’s not a randomized trial, sure, but the feedback mirrors what many customers say about modern PVC systems.

Final checks before you buy

- Ask for EN 14904 or ASTM F2772 test reports for the exact build you’re buying.

- Confirm substrate flatness tolerances and moisture specs; it saves headaches.

- Request VOC data (ISO 16000) if children use the space.

- Get a maintenance guide; most vinyl gym mat floors live or die by cleaning routines.

References:

- EN 14904:2018 – Surfaces for sports areas. Indoor surfaces for multi-sports use.

- ASTM F2772 – Standard Specification for Athletic Performance Properties of Indoor Sports Floor Systems.

- ISO 16000 series – Indoor air: VOC emission testing of building products.

- EN 13501‑1 / ISO 9239‑1 – Fire classification and reaction to fire tests for floorings.

-

Durable Volleyball Ground Mats for Safe & Competitive Play

NewsNov.24,2025

-

Premium Volleyball Court Mat: Safety, Durability & Performance for Global Play

NewsNov.23,2025

-

Durable and Eco-Friendly Rubber Play Mats Outdoor for Safer Playgrounds

NewsNov.22,2025

-

Comprehensive Guide to Types of Interlock Tiles: Materials, Uses & Trends

NewsNov.22,2025

-

Exploring Different Types of Interlocking Tiles: Global Uses and Benefits

NewsNov.21,2025

-

PVC Interlocking Floor Tiles Price – Comprehensive Guide for Smart Flooring Choices

NewsNov.20,2025