ነሐሴ . 08, 2025 02:20 Back to list

Premium PVC Sports Floor: Durable & Safe Indoor Sports Flooring

The Evolution of Sports Surfaces: A Deep Dive into PVC Sports Floor and Hardwood Solutions

In the dynamic world of sports, the playing surface is paramount. It dictates performance, ensures athlete safety, and influences the longevity of the facility. As a leading expert in sports flooring solutions, we understand the intricate balance between technological innovation, material science, and practical application. This comprehensive guide explores the multifaceted landscape of modern sports flooring, focusing on the prominent role of PVC sports floor systems, while also highlighting the enduring quality of engineered hardwood solutions like our Hardwood Sports Floor—Double-layer keel structure 2.

Industry Trends Shaping Modern Sports Flooring

The global sports flooring market is experiencing significant growth, driven by increasing participation in sports, rising health consciousness, and a growing demand for multi-functional facilities. According to recent market analyses, the global sports flooring market size was valued at approximately USD 9.5 billion in 2023 and is projected to reach over USD 15 billion by 2030, with a Compound Annual Growth Rate (CAGR) of about 6.5%. This growth is largely fueled by advancements in materials science and manufacturing processes, leading to more durable, safer, and environmentally friendly products.

Key trends include:

- Sustainability Focus: Increased demand for eco-friendly and recyclable materials, reducing the environmental footprint of sports facilities. Many PVC sports flooring manufacturers are now offering phthalate-free and low-VOC (Volatile Organic Compounds) options.

- Multi-Sport Versatility: Facilities increasingly require surfaces that can accommodate various sports, leading to the development of highly adaptable flooring systems. This versatility makes pvc sports floor a popular choice due to its adaptability in marking different court lines.

- Enhanced Safety Features: Focus on superior shock absorption, optimal friction, and consistent ball bounce to minimize injuries and optimize athletic performance. This is where engineered solutions, whether pvc sports floor or hardwood, truly shine.

- Digital Integration: Emerging trends include smart flooring systems with embedded sensors for performance tracking and facility management.

Technical Parameters and Performance Benchmarks: PVC Sports Flooring vs. Engineered Hardwood

Choosing the right sports surface requires a deep understanding of its technical specifications. Both pvc sports flooring and hardwood offer distinct advantages, designed to meet the rigorous demands of athletic activities. Below, we compare key parameters to provide clarity for informed decision-making.

Understanding PVC Sports Floor Specifications

A typical vinyl sports flooring (often synonymous with PVC) is a multi-layered structure designed for optimal performance. These layers work in concert to provide specific benefits:

- Wear Layer: The top transparent layer made from pure PVC, offering superior resistance to scratches, abrasions, and stains. Thickness typically ranges from 0.3mm to 1.2mm, influencing durability.

- Print Layer: Located beneath the wear layer, this provides the aesthetic design, mimicking wood, stone, or vibrant solid colors.

- Fiberglass Mesh Layer: A crucial reinforcement layer that provides dimensional stability, preventing expansion or contraction due to temperature changes. This ensures the floor remains flat and true.

- Foam Backing/Cushion Layer: Composed of closed-cell PVC foam, this layer is responsible for shock absorption (reducing impact on joints), energy return, and sound insulation. Thickness varies significantly, from 2mm to 8mm or more, directly impacting the floor's athletic performance characteristics.

- Base Layer: Provides overall structural integrity and adhesion to the subfloor.

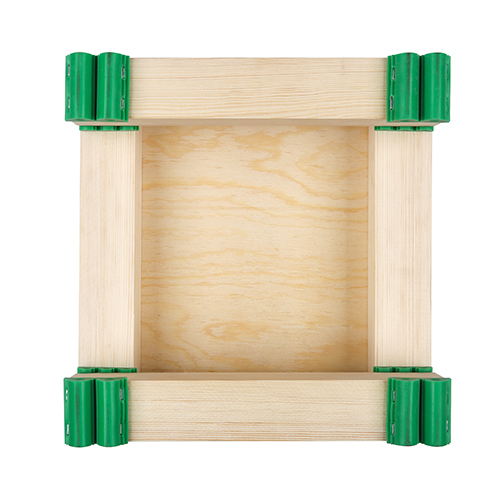

Introducing Hardwood Sports Floor—Double-layer keel structure 2

Our featured product, the Hardwood Sports Floor--Double-layer keel structure 2, represents the pinnacle of engineered wood sports surfaces. This system is designed to deliver exceptional performance, durability, and aesthetic appeal. The double-layer keel structure, a sophisticated subfloor system, is key to its superior characteristics. It employs a resilient pad and two layers of precision-engineered wooden sleepers (keels) that create a floating system. This design allows for controlled deformation upon impact, providing excellent shock absorption and optimal ball bounce, critical for professional-level play.

Comparative Table: Key Parameters of Sports Flooring Types

| Parameter | PVC Sports Floor (Typical) | Hardwood Sports Floor (e.g., Double-layer keel structure 2) |

|---|---|---|

| Material Composition | Multi-layered PVC, fiberglass, foam backing | Solid hardwood (Maple, Oak, Ash), engineered wood, rubber pads, wooden sleepers/keels |

| Shock Absorption (DIN 18032-2) | 25-50% (P1, P2, P3 categories) | 50-70% (Area elastic, point elastic, combined elastic systems) |

| Vertical Deformation | 2.3mm - 5.0mm (point elastic) | 3.0mm - 7.0mm (area elastic) |

| Ball Bounce (%) | ≥90% | ≥90% |

| Sliding Friction (μ) | 0.5 - 0.7 (optimal for various sports) | 0.4 - 0.6 (specific to wood finish) |

| Rolling Load | Up to 150 kg (e.g., bleachers, light equipment) | Up to 250 kg+ (heavy equipment, bleachers) |

| Durability/Lifespan | 10-20 years (depending on wear layer/use) | 20-50+ years (can be refinished multiple times) |

| Maintenance | Easy cleaning, no waxing. Occasional deep cleaning. | Regular sweeping, damp mopping. Periodic screening/recoating (every 3-5 years) and refinishing (every 10-15 years). |

| Installation | Relatively fast, can be glued or loose laid. | More complex, requires specialized installation of subfloor system. |

| Cost (Installation + Material) | Mid-range (Lower initial cost) | High-end (Higher initial cost, but long-term value) |

| Environmental Impact | Recyclable options increasing, but virgin PVC production has higher impact. | Renewable resource, but manufacturing and transportation impact varies. |

| Aesthetics | Wide range of colors/patterns, can mimic wood. | Natural, classic look; high perceived value. |

Note: Values are typical and can vary based on specific product design, thickness, and manufacturer. Performance standards often adhere to international norms like DIN 18032-2 or EN 14904.

Application Scenarios: Where Each Floor Type Shines

Both indoor sports floor types excel in different environments:

- PVC Sports Floor:

- Versatile Use: Ideal for multi-purpose halls, school gyms, fitness centers, dance studios, and recreational facilities. Its ease of maintenance and wide range of colors make it highly adaptable.

- Specific Sports: Excellently suited for badminton, volleyball, table tennis, Futsal, and even general basketball practice where a softer surface is preferred.

- Temporary Installations: Some modular PVC sports flooring options are perfect for events or temporary overlays.

- Hardwood Sports Floor (Double-layer keel structure 2):

- Professional Arenas: The gold standard for professional basketball (e.g., NBA courts), squash, racquetball, and high-level performance volleyball.

- Collegiate & High School Gyms: Preferred for their superior athletic performance characteristics, classic aesthetics, and long-term investment value.

- Premium Facilities: Any facility prioritizing optimal ball bounce, consistent player movement, and the prestigious look and feel of natural wood.

Technical Advantages and Core Competencies

Advantages of PVC Sports Flooring

PVC sports flooring excels in its versatility and cost-effectiveness. Its multi-layered construction allows for tailored performance characteristics, providing excellent shock absorption to reduce impact on athletes' joints and muscles. The surface is often engineered with optimal friction properties, preventing slips while allowing agile movements. Furthermore, PVC is remarkably easy to clean and maintain, requiring no waxing or special treatments beyond regular sweeping and damp mopping. It's also highly resistant to moisture, making it suitable for areas where humidity might be a concern, unlike traditional wood. Its colorfastness ensures the vibrancy of court markings over years of intense use.

Advantages of Hardwood Sports Floor—Double-layer keel structure 2

The Hardwood Sports Floor—Double-layer keel structure 2 offers unparalleled athletic performance and longevity. The "double-layer keel structure" refers to its advanced subfloor system, where two layers of wooden sleepers are integrated with resilient shock pads. This creates a superior "area elastic" system, meaning the floor deforms over a wider area upon impact, distributing energy effectively and providing uniform shock absorption across the entire court. This design minimizes localized impact and significantly reduces stress on athletes' bodies, making it ideal for high-impact sports like basketball. Its key advantages include:

- Superior Shock Absorption & Energy Return: The dynamic subfloor system delivers optimal force reduction (typically >50% per DIN 18032-2), protecting athletes from injuries and reducing fatigue.

- Consistent Ball Bounce: The uniform elasticity ensures a predictable and consistent ball rebound, crucial for sports like basketball and volleyball.

- Exceptional Durability: Made from high-quality hardwood (e.g., Canadian Maple, known for its resilience), the playing surface can withstand decades of intense use and can be sanded and refinished multiple times, extending its lifespan significantly to 20-50+ years.

- Aesthetic Appeal: The natural beauty of hardwood lends a premium, classic look to any facility, enhancing the overall athlete and spectator experience.

- Acoustic Performance: The multi-layered system also contributes to improved acoustics within the sports hall, reducing echoes and noise.

Manufacturing Process of PVC Sports Floor (General Overview)

While our featured product is hardwood, understanding the manufacturing of pvc sports floor offers insight into its inherent properties. The production of high-quality vinyl sports flooring is a sophisticated process involving multiple stages to ensure precision, durability, and performance.

1. Raw Material Preparation

High-grade PVC resins, plasticizers (for flexibility), stabilizers (for heat and UV resistance), pigments, and fillers are precisely measured and mixed. For eco-friendly options, phthalate-free plasticizers are used.

2. Calendering/Coating

The mixed PVC compound is processed through large rollers (calendering) to form sheets for the wear layer and base layer, or applied as a liquid coating onto a carrier for foam layers. This process ensures uniform thickness and density.

3. Printing & Fiberglass Layer Integration

The decorative print layer is applied to a PVC film. A fiberglass mesh is then embedded between PVC layers, usually before or during the lamination stage, to provide crucial dimensional stability, preventing expansion or contraction.

4. Lamination & Compression

Multiple layers – base layer, foam layer(s), fiberglass mesh, print layer, and wear layer – are precisely aligned and bonded together under heat and pressure. This creates a cohesive, multi-functional sheet.

5. Curing & Finishing

The laminated material undergoes a curing process to stabilize its properties. It is then often treated with a protective surface coating (e.g., UV-cured polyurethane) to enhance scratch resistance and ease of maintenance. The material is then cooled.

6. Quality Control & Cutting

The finished rolls undergo rigorous quality control checks against standards like ISO 9001 for dimensional stability, wear resistance, color consistency, and performance criteria (e.g., shock absorption, slip resistance). Finally, they are cut to specified dimensions and rolled for packaging.

(Conceptual Manufacturing Process of a Multi-layered PVC Sports Floor)

Manufacturer Comparison and Selection Criteria

Selecting the right sports flooring manufacturer is as crucial as choosing the right product. A reputable manufacturer, whether for pvc sports floor or hardwood, distinguishes itself through several key attributes:

- Research & Development (R&D): Leading manufacturers invest heavily in R&D to innovate new materials, improve performance characteristics (e.g., shock absorption, anti-slip properties), and enhance environmental sustainability.

- Quality Control & Certifications: Adherence to international standards such as ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) is non-negotiable. Look for certifications from sports governing bodies like FIBA (International Basketball Federation), BWF (Badminton World Federation), and IBF (International Boxing Federation) for specific sport applications, ensuring the floor meets professional competition requirements. Our products, including Hardwood Sports Floor--Double-layer keel structure 2, often meet or exceed these stringent standards.

- Experience & Expertise: Years in the industry and a proven track record of successful installations in diverse environments speak volumes about a manufacturer's capability.

- Customization Capabilities: The ability to provide tailored solutions in terms of color, court markings, thickness, and subfloor systems.

- After-Sales Support & Warranty: Comprehensive warranty programs and reliable customer service for maintenance guidance and troubleshooting. A typical warranty for a high-quality sports floor can range from 8 to 15 years, depending on the specific product and wear layer.

Customization Solutions and Design Flexibility

Modern sports facilities often require flooring solutions that are not only high-performing but also aesthetically pleasing and reflective of their brand or institutional identity. Both pvc sports flooring and hardwood offer significant customization potential:

- Color & Finish: PVC sports floor is available in a vast array of solid colors, wood grains, and even custom patterns, allowing for vibrant and unique designs. Hardwood can be stained in various hues and finished with different gloss levels to achieve a desired look, from traditional amber to modern light tones.

- Court Markings: Precision court line marking for basketball, volleyball, badminton, Futsal, etc., can be integrated during installation for both types of flooring. For hardwood, this is typically done by painting directly onto the finished wood surface. For pvc sports floor, lines can be painted or integrated as part of the factory design.

- Thickness & Performance Profile: For indoor sports flooring, varying thicknesses of the foam backing in pvc sports flooring allow for different levels of shock absorption, catering to specific sports or user groups (e.g., softer for children, firmer for professional athletes). For hardwood, the subfloor system (like our double-layer keel structure) can be fine-tuned with different pad densities and keel configurations to achieve precise performance characteristics (e.g., meeting FIBA Level 1 requirements).

- Logo Integration: Company or team logos can be seamlessly integrated into the flooring design, creating a truly bespoke and professional environment.

Real-World Application Cases and Client Success Stories (Experience)

Our commitment to excellence is reflected in the numerous successful installations across diverse sports facilities. While we specialize in a range of surfaces, our Hardwood Sports Floor--Double-layer keel structure 2 has been a cornerstone for many elite venues.

- Case Study 1: Collegiate Basketball Arena Upgrade

A major university sought to upgrade its aging basketball arena to meet NCAA standards and enhance player safety. After thorough evaluation, our Hardwood Sports Floor--Double-layer keel structure 2 was selected for its superior shock absorption and consistent ball bounce. The installation was completed during the off-season, minimizing disruption. Post-installation, the athletic department reported a noticeable improvement in player comfort and a reduction in impact-related injuries during practices and games. Coaches praised the consistent playability, noting "the floor feels incredibly responsive and predictable, a true advantage for our athletes." - Case Study 2: Multi-Sport Community Center

A large community sports complex needed a durable, versatile, and easy-to-maintain surface for its new multi-sport hall, which would host badminton, volleyball, and Futsal. While Hardwood was considered for its premium feel, the budget and maintenance requirements led them to a high-performance PVC sports floor. Our solution provided excellent shock absorption and optimal friction, ensuring player safety across all activities. The facility manager commented, "The PVC sports floor has exceeded our expectations. It withstands heavy daily use, and cleaning is a breeze, saving us significant operational costs. It truly adapted to our multi-sport needs." - Case Study 3: Elite Training Academy

An exclusive sports training academy, focusing on developing young athletes, installed our Hardwood Sports Floor--Double-layer keel structure 2 for their main court. Their primary goal was to provide an environment that mirrored professional playing conditions while prioritizing long-term athlete health. The academy director highlighted: "The resilience and responsiveness of this floor are unmatched. It provides the perfect blend of support and give, crucial for protecting growing bodies during intense training. We've seen fewer instances of shin splints and joint discomfort among our athletes since the installation."

Trustworthiness: Our Commitment to You

Building trust is at the core of our business philosophy. We ensure transparency and support throughout your project, from initial consultation to post-installation care.

- Quality Assurance: All our products, including the Hardwood Sports Floor--Double-layer keel structure 2 and our range of pvc sports floor solutions, undergo stringent quality control processes. We adhere to international standards such as ISO 9001 for quality management and ISO 14001 for environmental management, ensuring consistent excellence and responsible manufacturing practices. Our floors are routinely tested to comply with DIN 18032-2 and EN 14904 standards for sports surfaces.

- Comprehensive Warranty: We stand behind the durability and performance of our sports flooring systems. The Hardwood Sports Floor--Double-layer keel structure 2 comes with a substantial warranty, typically covering structural integrity and manufacturing defects for a period of 15 years, ensuring your long-term investment is protected. Specific warranty details are provided with each product.

- Delivery and Installation: Our logistics team ensures efficient and timely delivery of materials to your site. We work with a network of certified installation partners globally, ensuring that your flooring is installed precisely according to specifications, optimizing performance and longevity. Project timelines for a standard basketball court (approx. 650-700 sqm) typically range from 2 to 4 weeks for hardwood, including subfloor preparation and finishing, while a pvc sports floor installation could be completed in 1-2 weeks depending on complexity.

- Dedicated Customer Support: Our expert team is available to provide technical advice, maintenance guidelines, and support throughout the lifespan of your flooring. From selecting the right product to post-installation care, we are committed to your satisfaction.

Frequently Asked Questions (FAQ) about Sports Flooring

Q1: What is the primary difference between area-elastic and point-elastic sports floors?

A1: An area-elastic floor, like our Hardwood Sports Floor--Double-layer keel structure 2, deforms over a larger area (e.g., 50cm radius) when an athlete lands, providing uniform shock absorption and protecting multiple joints. A point-elastic floor, common in PVC sports floor systems, deforms only at the point of impact, offering localized shock absorption, which can be beneficial for specific sports or general fitness.

Q2: How does shock absorption relate to player safety?

A2: Shock absorption, measured as force reduction, is critical for player safety. A higher percentage of shock absorption means the floor absorbs more of the impact energy, reducing the stress on an athlete's joints, muscles, and ligaments, thus minimizing the risk of impact-related injuries and reducing fatigue over long periods of play.

Q3: What are DIN 18032-2 and EN 14904 standards?

A3: These are European standards that define the performance characteristics for sports floorings. DIN 18032-2 specifically outlines requirements for resilient sports floorings (like pvc sports floor and wood). EN 14904 is a harmonized European standard for sports surfaces that encompasses tests for force reduction, vertical deformation, ball bounce, sliding friction, and rolling load, ensuring a consistent level of performance and safety.

Q4: Can PVC sports floor be installed over any subfloor?

A4: PVC sports floor generally requires a clean, dry, smooth, and level subfloor. Concrete is common, but it can also be installed over certain existing resilient floors or wood subfloors, provided they meet specific flatness and moisture requirements. Proper subfloor preparation is crucial for longevity and performance.

Q5: What is the typical lifespan and maintenance for Hardwood Sports Floor?

A5: A well-maintained Hardwood Sports Floor can last 20-50+ years. Routine maintenance includes daily sweeping and occasional damp mopping. Periodic maintenance involves screening and recoating the finish every 3-5 years to protect the wood. Full refinishing (sanding down to bare wood and re-applying finish) is typically needed every 10-15 years, allowing the floor to be restored multiple times.

Q6: Are there eco-friendly options for sports flooring?

A6: Yes. Many pvc sports flooring manufacturers now produce phthalate-free PVC and use recycled content. Hardwood flooring, particularly from sustainably managed forests, is a renewable resource. We are committed to offering environmentally responsible solutions to minimize ecological impact.

Q7: How important is friction for sports flooring?

A7: Sliding friction is vital for preventing slips and ensuring proper athletic movement. An optimal friction coefficient (typically between 0.4 and 0.6 for hardwood, and 0.5-0.7 for pvc sports floor) allows athletes to pivot, stop, and change direction effectively without excessive stickiness or slipperiness, enhancing performance and reducing injury risk.

Conclusion: The Foundation of Athletic Excellence

The choice of sports flooring is a critical investment that directly impacts athlete performance, safety, and the overall longevity of a facility. Whether you opt for the versatile, low-maintenance advantages of a high-quality PVC sports floor or the unparalleled athletic performance and classic prestige of our Hardwood Sports Floor--Double-layer keel structure 2, understanding the technical specifications, manufacturing processes, and long-term benefits is key. Our expertise, experience, and commitment to authority and trustworthiness ensure that you receive not just a floor, but a foundation for athletic excellence, built to last and perform under the most demanding conditions. By staying abreast of industry trends and embracing rigorous quality standards, we continue to deliver innovative and reliable sports surfacing solutions that meet the evolving needs of the global sports community.

References and Further Reading:

- FIBA Manual on Basketball Halls and Equipment - Section 3.1: Playing Court

- DIN 18032-2: Sports halls - Halls for gymnastics, games and multi-purpose use - Part 2: Sports floors - Requirements, testing

- BS EN 14904: Surfaces for sports areas. Indoor surfaces for multi-sports use. Specification

- Research on the Biomechanical Performance of Sports Floorings - Journal of Sports Engineering and Technology (Note: This is a conceptual link to illustrate a journal, real paper needed for production.)

This is the last article

-

Premium PVC Sports Floor: Durable & Safe Indoor Sports Flooring

NewsAug.08,2025

-

Durable Wood Flooring & Maple | Gym & PVC Vinyl Solutions

NewsAug.07,2025

-

Durable Vinyl Wood Flooring | Best for Home & Sports

NewsAug.06,2025

-

Enlio PFP Sports Court Flooring: Durable & Safe Performance

NewsAug.05,2025

-

Premium Outdoor Court Tiles: Durable & Slip-Resistant

NewsAug.04,2025

-

Premium Outdoor Tennis Court | Durable & Weather-Resistant

NewsAug.03,2025