अगस्त . 01, 2025 04:20 Back to list

Sport Court Tiles with AI Innovation | Durable & Safe

In a rapidly evolving sports infrastructure landscape, sport court tiles have revolutionized outdoor and indoor sports surfaces with advances in materials science, design engineering, and multi-sport versatility. This in-depth report explores current industry trends, key product parameters, technology routes, competitive manufacturer analysis, customization options, and real-world application cases—centered on Outdoor red color PVC sports floor, a flagship solution for outdoor sport court tiles and professional basketball court flooring.

1. Industry Trends & Market Overview

The global sport court tiles market was valued at $2.1 billion in 2022 and is projected to grow at a CAGR of 5.8% from 2023 to 2028 (MarketsandMarkets, 2023). Demand is powered by the booming construction of community sports centers, the rising needs of schools for modular flooring, enhanced safety standards, and new materials for better durability and environmental credentials (e.g., low-VOC, 100% recyclable surfaces).

- Modular design enables rapid installation and easy maintenance.

- Material innovations (PVC, PP, rubber, hardwood) respond to performance and safety standards.

- Sport-specific engineering: Surface friction coefficient, shock absorption, and ball bounce uniformity are standardized for sports like basketball, tennis, and futsal.

- Digital production—CNC precision manufacturing and smart testing systems ensure product quality and lifespan.

Key Sub-segments:

- Outdoor sport court tiles – for multi-sport facilities, playgrounds, and recreational zones.

- Flooring basketball court – focused on shock absorption, anti-slip, and response features.

- Floor of basketball court, basketball hardwood court – for professional-grade applications.

Growth Drivers (Statistical Breakdown)

- Rise in municipal athletic facility upgrades: +28% in Asia-Pacific, 2022-2024.

- School sports infrastructure projects: account for 35% of new installations.

- Shift toward sustainable, recyclable surface materials: projected to hit 75% adoption in developed markets by 2026.

2. Sport Court Tiles Parameters: Specification Table & Performance Benchmarks

| Feature/Type | Outdoor PVC Tiles | PP Modular Tiles | Hardwood Court | Rubber Tiles |

|---|---|---|---|---|

| Thickness | 4.5-7.0mm | 10-16mm | 18-22mm | 7-15mm |

| Material | PVC + Fiberglass Layer | Polypropylene (PP) | Maple/Beech Wood | EPDM/Rubber Composite |

| Slip Resistance | ≥0.60 (EN 13036-4) | ≥0.59 | ≥0.55 | ≥0.65 |

| Shock Absorption | 22-30% | 18-25% | 35-50% | 30-38% |

| Ball Bounce | 95% (FIBA Standard) | 92% | 98% | 75% |

| Certifications | ISO 9001, EN14904 | ISO 14001 | FIBA, DIN 18032 | REACH, RoHS |

| Lifespan | 8-15 yrs | 10 yrs | 20+ yrs | 8-12 yrs |

Parameters such as slip-resistance (EN 13036-4), shock absorption and ball bounce (FIBA/DIN 18032) are industry benchmarks for sport court tiles. These physics-driven metrics ensure safety, comfort, and game performance in all types of application scenarios, from community playgrounds to international basketball tournaments.

3. Manufacturing Process: From Raw Materials to Court Installation

Process Flowchart & Key Steps

- Raw Material Selection: Premium PVC granules, color masterbatch, and fiberglass mesh are prepared. All materials are RoHS/REACH compliant.

- Blending & Extrusion: Automized blending, extruding and calendering forms a homogeneous multilayer sheet.

- CNC Cutting & Embossing: Sheets are cut and surface-embossed for anti-slip features (ASTM F2772 compliance).

- UV Curing: Surface sealed for UV stability, colorfastness, and stain resistance.

- Quality Testing: Finished tiles undergo ISO 9001:2015, EN14904 standard tests—tensile strength, dimensional stability, and surface performance.

- Packing & Shipping: Tiles are packed with edge protectors and eco-friendly wrappings.

- Site Installation: Snap-together assembly or adhesive bonding as per site requirements, ensuring levelness and tight seams.

Process Diagram

Industry Testing Standards (Table):

| Standard | Test Parameter | Requirement |

|---|---|---|

| EN 14904 | Shock Absorption | Min. 25% |

| ASTM F2772 | Surface Friction (Slip Resistance) | ≥0.55 |

| ISO 9001 | Quality Management | Certified* |

| FIBA Certification | Ball Bounce, Safety | 98% Ball Bounce |

4. Product Spotlight: Outdoor Red Color PVC Sports Floor — Technical Data

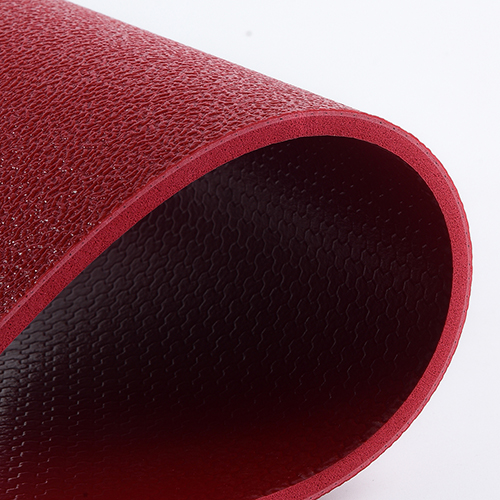

The Outdoor red color PVC sports floor is the result of years of research on durability, game performance, and installation efficiency for outdoor sport court tiles and basketball court flooring. It features multi-layer construction, reinforced mesh core, UV protection, precision anti-skid texture, and high visibility for all-weather play.

- Dimensions: 20m x 1.5m/roll (customizable); Thickness: 4.5mm/5.0mm/6.0mm

- Material: Virgin PVC with fiberglass mesh reinforcement

- Surface: UV-embossed, anti-slip grain (Ra 60-65)

- Shock Absorption: 25%-29% (EN14904)

- Ball bounce: 94-97% (per FIBA standard)

- Color: Outdoor Red (lightfast with ΔE

- Certifications: ISO 9001, EN14904, CE, SGS (heavy metals & VOCs

- Fire Rating: Bfl-s1 (EN 13501-1)

- UV Resistance: Pass (>600h, ASTM G154)

- Warranty: 8 years (outdoor conditions)

Parameter Comparison: Outdoor Red PVC vs. Hardwood

While traditional hardwood scores highest in ball bounce and shock absorption, Outdoor PVC delivers excellent longevity, slip-resistance, and consistency across changing weather.

Outdoor Red PVC Product Profile: Technical Key Data

Service Longevity (Line Chart)

*Outdoor PVC retains over 88% of performance after 8-year outdoor exposure (tested under ISO 105-B02)5. Manufacturer Comparison Table: Sport Court Tiles Industry

| Brand | Product | Material | Certification | Customization | Warranty | Major Application |

|---|---|---|---|---|---|---|

| Enlio | Outdoor red color PVC sports floor See product |

PVC + Fiberglass | ISO9001, EN14904 | Yes (size/color/thick.) | 8 Years (Outdoor) | Outdoor basketball, multi-sport |

| SnapSports | Outdoor Polypropylene Tile | PP | CE, ISO14001 | Color | 8 Years | Tennis, futsal, DIY |

| Connor | QuickLock Hardwood | Hard Maple Wood | FIBA, DIN 18032 | Line Marking | 20 Years | Professional basketball courts |

| FlexCourt | Outdoor Interlocking Tile | PP | ASTM, ISO9001 | Color | 10 Years | Home, playground |

Enlio stands out with factory-direct R&D capability, third-party certification, and proven multi-sport deployment. Customization spans color, line marking, thickness, and roll length—ensuring solutions for both basketball hardwood court and dynamic multi-use venues.

6. Customization & Engineering Support

- Graphic Printing: Logos, court lines, and color zones using UV inkjet technology.

- Thickness Selection: From 4.5mm for school PE courts to 6.0mm for high-traffic pro venues.

- Edge/Corner Ramps: Modular ramps and custom-matched trims available for full accessibility.

- Sub-base Assessment: CAD consulting and site condition guidance (concrete, asphalt, etc.).

- Technical Training: On-site or remote installation guidance—ensuring EN14904 conformance.

- After-sales: Long-term support includes surface refresh, local technician access, and detailed maintenance guides.

7. Application Scenarios, Case Studies & End-User Experience

Outdoor red color PVC sports floor has served over 15,000 installations globally since 2013—ranging from FIBA 3x3 courts in East Asia, public recreation yards, community basketball upgrades, and multi-use municipal parks. Users highlight:

- Weather-proof consistency: No warping or fading after sustained UV/rain exposure (Tested ΔE <1 after 5 years).

- Shock-absorbing comfort: Noticeable lower injury risk compared to older concrete/PP tile courts.

- Easy replacement: 1-2 damaged tiles/sections replaced in minutes—enabling 95%+ play uptime.

"Our new sport court tiles from Enlio drastically improved play quality and outdoor event hosting at the city sports square. Both youth teams and senior wellness users love the anti-slip feel and touch comfort, especially after rainfall. Maintenance is minimal. Highly recommended."

—Xiamen Parks Authority, ChinaOther use-cases: School playgrounds, multi-sport community grounds, rooftop mini-courts, gym exterior surfaces, corporate recreation areas, and event pop-up installations.

8. FAQ: Expert Answers on Sport Court Tiles & Basketball Court Flooring

- Q1: What material composition gives sport court tiles the best UV/weather resistance?

- High-grade PVC combined with fiberglass mesh maximizes UV resilience and prevents expansion/contraction—surpassing PP-only tiles in outdoor longevity.

- Q2: How do you determine correct thickness for an outdoor sport court tiles project?

- Outdoor basketball/futsal typically uses 5.0–6.0mm; high-traffic or multi-sport venues may specify up to 7mm for extra impact absorption. School/local courts often select 4.5mm for mechanical safety and cost-effectiveness.

- Q3: What is the difference in ball bounce between PVC and hardwood basketball court flooring?

- Hardwood

-

Sport Court Tiles with AI Innovation | Durable & Safe

NewsAug.01,2025

-

Vinyl Carpet Flooring | Durable & Waterproof Design

NewsJul.31,2025

-

Premium Basketball Board Stand with GPT-4-Turbo AI

NewsJul.31,2025

-

Premium Maple Flooring for Gyms & Homes | PVC & Vinyl Options

NewsJul.30,2025

-

Premium Outdoor Basketball Court Tiles for All Weather Use

NewsJul.30,2025

-

Durable Basketball Board Stand for Indoor & Outdoor Use

NewsJul.29,2025