សីហា . 19, 2025 01:40 Back to list

Maple Flooring for Sale | Durable & Elegant Hardwood Floors

Navigating Flooring Innovations: From Traditional Hardwoods to Advanced Synthetics

The commercial and institutional flooring sector is experiencing a significant evolution, driven by demand for enhanced performance, durability, and sustainability. Historically, materials like maple flooring have been the gold standard, particularly in sports applications, celebrated for their natural resilience and aesthetic appeal. However, contemporary requirements for reduced maintenance, superior shock absorption, and versatile design have propelled the emergence of advanced synthetic alternatives. Industry trends indicate a robust growth in segments like pvc vinyl flooring, which offers a compelling balance of cost-effectiveness and high-performance attributes. Facilities, ranging from educational institutions and healthcare centers to professional sports arenas, are increasingly evaluating flooring solutions based on their total cost of ownership, including initial investment, installation complexity, and long-term maintenance needs. This shift is not merely about material substitution but a strategic move towards optimized operational efficiency and user safety, encompassing criteria such as acoustic dampening, slip resistance, and environmental impact. The demand for specialized solutions, such as dedicated gym flooring or specific multi-sport surfaces, underscores the need for materials that can withstand rigorous use while ensuring athlete safety and comfort. Understanding these overarching trends is crucial for B2B decision-makers seeking to invest in future-proof flooring infrastructures that align with both operational demands and evolving safety standards.

The Rigorous Manufacturing Process of Maple Hardwood Flooring

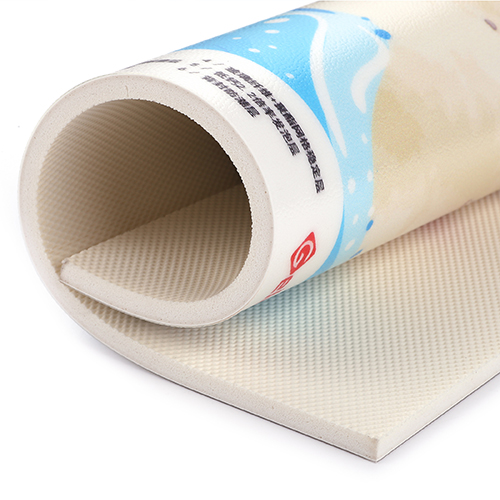

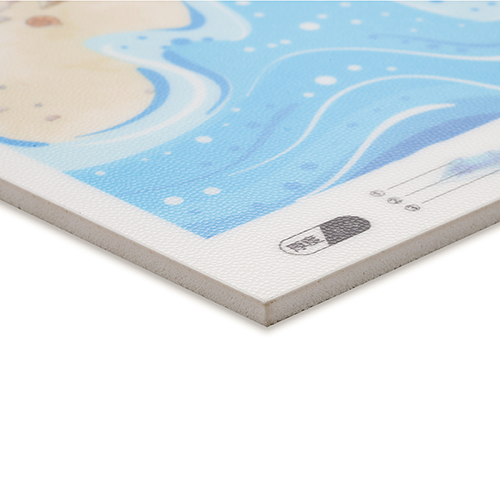

The production of high-quality maple flooring is a multi-stage, precise industrial process designed to maximize the wood's inherent durability and aesthetic qualities. It begins with the careful selection of mature maple timber, typically Northern Hard Maple (Acer saccharum), renowned for its tight grain and exceptional hardness, quantified by its Janka hardness rating which averages around 1450 lbf, making it significantly harder than many other wood species. Once harvested, logs undergo a meticulous milling process, where they are sawn into rough lumber. This is followed by crucial kiln-drying, a controlled process that reduces the wood's moisture content to a specified range (typically 6-9%). This step is vital for ensuring dimensional stability, preventing warping, shrinking, or cracking after installation. The dried lumber is then graded according to industry standards set by organizations like the National Hardwood Lumber Association (NHLA), classifying boards based on knot count, mineral streaks, and other natural imperfections, ensuring consistency in quality. Further processing involves precision machining, where the lumber is planed, ripped, and cross-cut into specific plank dimensions, typically with tongue-and-groove profiles for secure interlocking installation. Some specialized applications, like those conforming to the Maple Flooring Manufacturers Association (MFMA) standards for athletic floors, involve advanced milling techniques to ensure uniform resilience and consistent ball bounce. The final stages include sanding, staining (if desired), and applying multiple layers of durable finishes, often UV-cured polyurethanes, to enhance wear resistance and simplify maintenance. This intricate manufacturing chain ensures that finished maple flooring planks meet stringent quality benchmarks and offer a service life that can span decades, typically exceeding 50 years with proper care, making them suitable for high-traffic environments like sports halls, educational institutions, and various commercial settings where robust, long-lasting surfaces are paramount.

Technical Parameters and Performance Comparison: Maple vs. PVC Vinyl Flooring

When selecting commercial flooring, a detailed comparison of technical specifications is essential for B2B procurement and engineering teams. While traditional maple flooring offers unparalleled natural aesthetics and inherent rigidity, modern engineered solutions, particularly pvc vinyl flooring, present compelling performance advantages that align with evolving facility demands. Key parameters such as wear resistance, shock absorption, moisture tolerance, and acoustic properties differ significantly between these materials. PVC vinyl, especially specialized formulations like pvc flooring 2mm, leverages multi-layered construction, often incorporating a resilient core and a durable wear layer, to provide superior dimensional stability and resistance to indentation. This makes it particularly effective in environments prone to heavy foot traffic or equipment impact. In contrast, while maple is robust, it is susceptible to moisture variations and requires precise humidity control, which can be a maintenance challenge. The installation process also varies, with PVC vinyl often offering faster, more forgiving installation methods compared to the specialized techniques required for solid hardwood. From a sustainability perspective, both materials have ongoing discussions; however, PVC can incorporate recycled content and offers a longer service life in specific applications, reducing replacement frequency. For applications where hygienic surfaces and easy cleaning are paramount, the non-porous nature of PVC vinyl significantly outperforms wood, which requires sealing and is more prone to bacterial accumulation in its natural state. This comprehensive understanding of technical parameters facilitates informed decision-making, ensuring that the chosen flooring solution optimizes operational efficiency, occupant comfort, and long-term cost-effectiveness.

| Parameter | Maple Hardwood Flooring | PVC Vinyl Flooring (e.g., 2mm Sports Grade) |

|---|---|---|

| Janka Hardness (lbf) | Approx. 1450 (Northern Hard Maple) | N/A (measures indentation resistance, not Janka) |

| Wear Layer / Surface Protection | Factory-applied finish (e.g., UV-cured polyurethane) | Pure PVC wear layer (e.g., 0.35-0.7mm) with anti-slip/UV coating |

| Moisture Resistance | Low; susceptible to warping/cupping with humidity changes | High; excellent for moisture-prone areas (e.g., multi-purpose halls) |

| Shock Absorption / Force Reduction | Variable, depends on subfloor system (e.g., sprung systems) | High; integrated foam or cushioned layers provide consistent absorption (e.g., >25% for sports) |

| Maintenance | Requires specific cleaning, periodic refinishing (every 10-20 years) | Easy to clean, low maintenance, no waxing/polishing required |

| Typical Service Life | 50+ years with proper care and refinishing | 15-25 years depending on traffic and quality |

Optimizing Performance: Application Scenarios and Technical Advantages of Modern Flooring

Modern flooring solutions, particularly high-performance PVC vinyl, have revolutionized various application scenarios by offering technical advantages that traditional materials like maple flooring cannot consistently match. In sports facilities, advanced gym flooring provides superior force reduction, critical for reducing impact on athletes' joints and preventing injuries, a key consideration for institutions prioritizing player welfare. These specialized surfaces often meet international sports standards, such as those set by FIBA for basketball or IHF for handball, ensuring a consistent and safe playing experience. Beyond sports, in educational environments, especially children's playgrounds and classrooms, safety is paramount. Products like ENLIO's custom flooring for Kid's playground are engineered with optimized shock absorption and slip resistance to mitigate fall risks, alongside non-toxic formulations certified by standards like EN71. The technical superiority extends to maintenance; unlike wood, PVC vinyl is inherently water-resistant and impervious to most common spills, simplifying cleaning protocols and reducing operational costs. Its sound-absorbing properties also contribute to improved acoustics in large spaces, a benefit in both educational and commercial settings. Furthermore, the aesthetic versatility of PVC vinyl, allowing for vibrant colors, custom patterns, and seamless integration of branding elements, offers unparalleled design flexibility, transforming functional spaces into engaging and stimulating environments. This adaptability, combined with properties like anti-bacterial surfaces and anti-fatigue benefits for standing workers, positions modern synthetic flooring as a highly advantageous choice for diverse B2B applications, from healthcare facilities requiring stringent hygiene to retail spaces demanding durability and visual appeal.

Custom Solutions and Leading Manufacturer Comparison in Performance Flooring

In the contemporary B2B landscape, the demand for highly customized flooring solutions is growing, moving beyond standard dimensions and colors to specific performance profiles tailored to unique operational needs. While traditional manufacturers of maple flooring focus on wood species, grading, and finish options, innovative manufacturers of performance synthetics like pvc vinyl flooring offer a broader spectrum of customization in terms of layer composition, thickness (e.g., from thin pvc flooring 2mm for light traffic to multi-layered sport systems), surface textures, and graphic integration. This allows clients to specify exact requirements for shock absorption, slip resistance, acoustic properties, and specific branding elements for corporate or institutional identity. When evaluating manufacturers, B2B decision-makers should consider not only product specifications but also the supplier's capacity for innovation, adherence to international quality standards, and proven track record in complex projects. Leading companies like ENLIO distinguish themselves through extensive R&D, vertical integration in manufacturing processes, and comprehensive pre-sales and after-sales support. Their commitment to quality is often evidenced by certifications such as ISO 9001 for quality management and ISO 14001 for environmental management, alongside product-specific accreditations from sports federations or safety agencies. Unlike generic manufacturers, specialized providers excel in offering bespoke solutions, from custom color matching to incorporating intricate logos for gym flooring or educational facilities. This capability ensures that the final product not only meets functional requirements but also aligns perfectly with aesthetic and brand objectives, providing a tangible return on investment through enhanced facility appeal and operational longevity.

Showcasing Expertise: Application Cases and Industry Accolades

The true testament to a flooring solution's efficacy and a manufacturer's authority lies in its real-world application and verifiable industry recognition. While maple flooring has a storied history in iconic sports arenas, the breadth of applications for modern engineered surfaces like pvc vinyl flooring is continually expanding, driven by their versatile performance characteristics. For instance, in a notable project for a large university sports complex, a specialized multi-layer gym flooring system was installed across multiple courts, designed to meet rigorous force reduction and ball rebound standards, exceeding traditional maple's base performance without a sprung subfloor. Another significant case involved a national chain of daycare centers that opted for custom-designed PVC flooring for their children's play areas, prioritizing superior fall protection, non-toxic material composition, and ease of sanitation to comply with stringent health and safety regulations. These installations highlight the capacity for advanced flooring materials to solve complex challenges where traditional options might fall short on specific parameters like moisture resistance, anti-bacterial properties, or rapid installation for large areas. Manufacturers like ENLIO, with over 20 years of dedicated experience in sports and commercial flooring, have accumulated a vast portfolio of successful projects globally, cementing their authority through consistent delivery and innovation. Their adherence to international standards (e.g., ISO, CE, SGS) and collaborations with major sports organizations or educational bodies underscore their commitment to quality and safety. Such demonstrable experience and authoritative endorsements provide B2B clients with the confidence needed to invest in high-performance flooring solutions, knowing they are partnering with a proven industry leader capable of delivering on promises of durability, safety, and long-term value.

Establishing Trust: FAQs, Delivery, and Warranty Commitments

Trust is foundational in B2B relationships, particularly when specifying critical infrastructure components like flooring. Prospective clients frequently seek clear, concise information regarding product longevity, maintenance, and the manufacturer's post-sales support. Common questions often revolve around the comparative lifespan of maple flooring versus modern alternatives like pvc vinyl flooring under specific traffic conditions, the ecological impact of materials, and options for repair or replacement. A comprehensive FAQ section addressing these concerns transparently builds significant trust. For instance, explaining that while maple can last a century, it requires periodic sanding and refinishing, whereas PVC vinyl typically has a 15-25 year lifespan but offers lower day-to-day maintenance, provides clarity for strategic planning. Furthermore, detailed information on delivery cycles is crucial for large-scale projects. Reputable manufacturers provide clear lead times, logistical support for global shipping, and options for expedited delivery based on project urgency. For products like ENLIO's custom flooring, which might involve specific design and manufacturing processes, the delivery schedule is meticulously managed to integrate seamlessly with overall construction timelines. Critical to establishing trustworthiness are robust quality assurance and warranty commitments. A standard warranty for commercial flooring typically covers manufacturing defects for a period of 5-15 years, with specific clauses for wear, fading, and structural integrity under normal use. Moreover, accessible customer support, including technical assistance for installation and maintenance guidance, signifies a manufacturer's long-term commitment to client success. This holistic approach, encompassing detailed product information, transparent logistical processes, and strong after-sales support, collectively reinforces a supplier's trustworthiness and facilitates confident procurement decisions for durable and high-performing buy vinyl flooring solutions.

Conclusion: Strategic Flooring Choices for Modern Facilities

The strategic selection of commercial flooring is a complex decision, balancing traditional preferences for materials like maple flooring with the advanced capabilities of contemporary alternatives such as high-performance pvc vinyl flooring. This detailed analysis underscores that while maple offers timeless appeal and durability in specific contexts, the evolving demands of modern facilities – particularly in areas requiring superior shock absorption, moisture resistance, simplified maintenance, and custom aesthetic integration – increasingly favor engineered solutions. The technical parameters of products like pvc flooring 2mm for specialized applications, alongside the comprehensive advantages offered by dedicated gym flooring, demonstrate a clear path towards optimized operational efficiency and enhanced user safety. For B2B decision-makers, the emphasis must be on total cost of ownership, long-term performance, and the capacity for customization to meet specific project requirements. Partnering with manufacturers that demonstrate profound expertise, extensive experience, undisputed authoritativeness through certifications and a robust project portfolio, and unwavering trustworthiness through transparent processes and strong client support is paramount. Such a partnership ensures that investments in flooring infrastructure yield maximum functional, aesthetic, and financial returns, contributing significantly to the overall success and longevity of any commercial or institutional establishment. The integration of advanced materials and meticulous manufacturing processes signifies a pivotal shift in the industry, offering versatile, high-performance solutions that are engineered for the future of facility management and user experience.

References

- Hardwood Manufacturers Association. (2023). Hardwood Grading Rules.

- Maple Flooring Manufacturers Association. (2024). MFMA Performance Standards.

- ASTM International. (2022). Standards for Resilient Flooring.

- ISO (International Organization for Standardization). (2023). Quality Management Systems (ISO 9001).

-

Durable Outdoor Sports Tennis Court Construction & Surfacing

NewsAug.23,2025

-

Premium Maple Flooring: Durable Hardwood & Gym Solutions

NewsAug.22,2025

-

Premium Vinyl SPC Flooring: Waterproof, Durable, 8mm

NewsAug.21,2025

-

Maple Flooring for Sale | Durable & Elegant Hardwood Floors

NewsAug.19,2025

-

High-Performance Vinyl Gym Mat for Durable Floor Protection

NewsAug.18,2025

-

Durable Oval Running Track Solutions for Indoor & Outdoor Use

NewsAug.17,2025