Sep . 08, 2025 14:46 Back to list

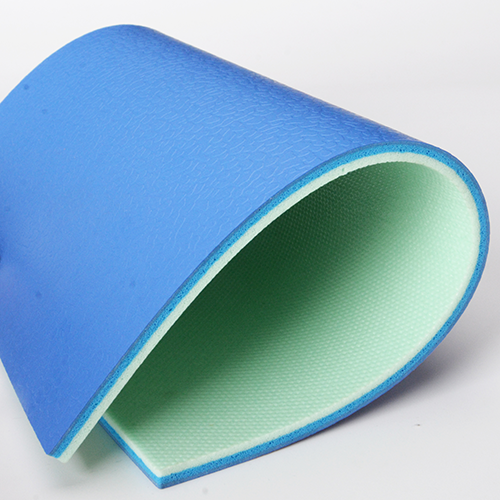

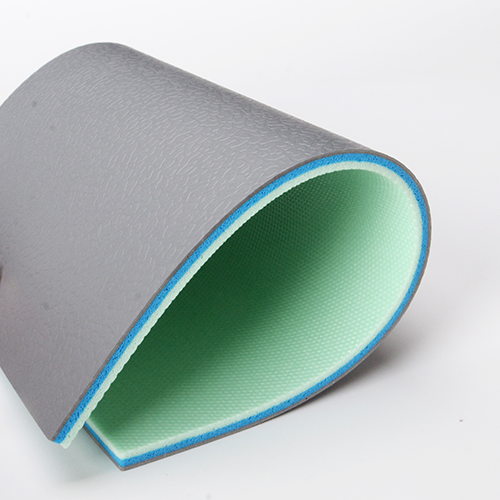

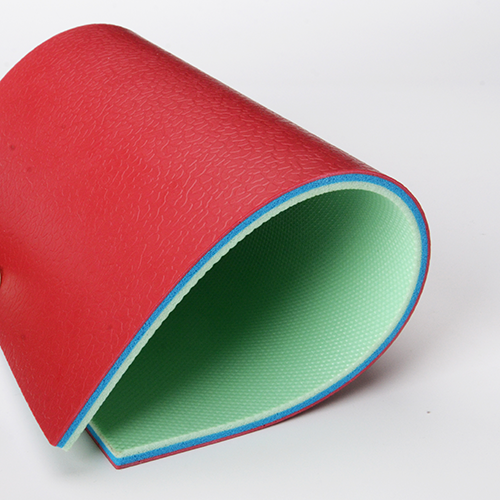

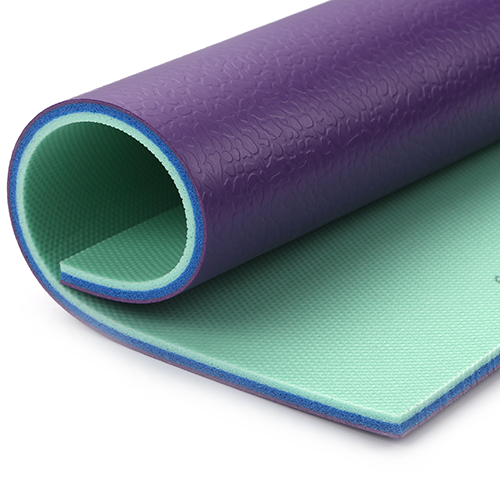

Multi-layer PVC Sports Flooring

Industry Trends and the Evolving Landscape of Performance Flooring

The modern sports and fitness industry demands high-performance flooring solutions that not only ensure athlete safety but also contribute to facility longevity and aesthetic appeal. In this dynamic environment, the vinyl gym mat has emerged as a predominant choice, setting new benchmarks for durability, resilience, and multi-functional adaptability. Market analysis indicates a significant CAGR in the sports flooring segment, driven by increasing participation in indoor sports, stringent safety regulations, and the expansion of fitness centers globally. Innovations in material science are continuously enhancing the properties of vinyl-based flooring, positioning it as a superior alternative to traditional options like hardwood or poured rubber.

Contemporary facility design prioritizes modularity and ease of maintenance, areas where advanced vinyl solutions excel. Unlike conventional options, modern vinyl products offer superior resistance to moisture, microbial growth, and impact, making them ideal for high-traffic, multi-purpose athletic environments. Furthermore, the aesthetic versatility of vinyl, available in a vast array of colors and patterns, allows facilities to achieve sophisticated interior designs without compromising functional integrity. This trend towards integrated performance and design is reshaping procurement decisions for B2B stakeholders in sports, education, and commercial real estate sectors.

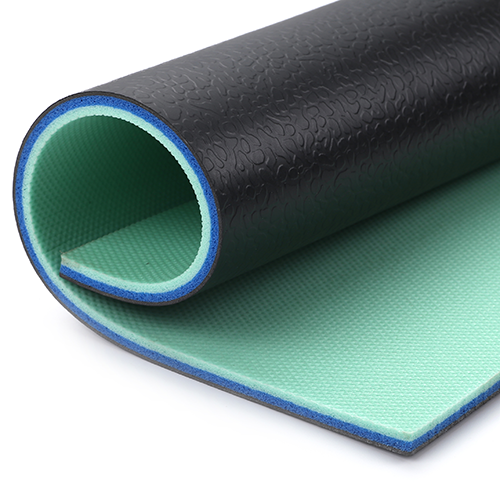

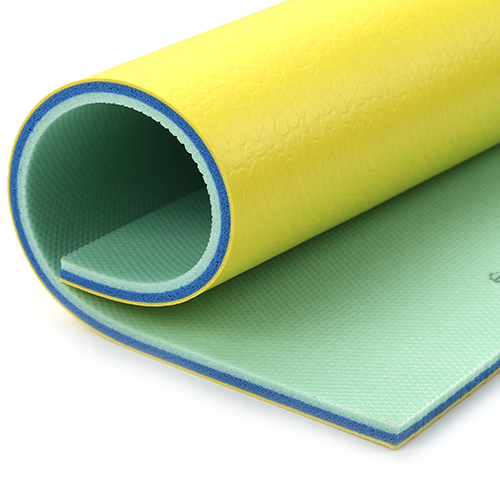

Technical Specifications: Multi-Layer PVC Sports Flooring with Gem Surface 6.0

Our flagship product, the multi-layer PVC Sports Flooring with gem surface 6.0, exemplifies cutting-edge engineering in performance flooring. This advanced solution is meticulously engineered to deliver optimal athletic performance and long-term durability, crucial for high-intensity sports environments. The structural integrity is derived from a proprietary multi-layer composition, each layer designed to fulfill a specific functional requirement, from load distribution to energy return.

Product Specification Table: Multi-Layer PVC Sports Flooring with Gem Surface 6.0

| Parameter | Specification |

|---|---|

| Product Name | Multi-Layer PVC Sports Flooring with Gem Surface 6.0 |

| Material Composition | High-grade Virgin PVC Resin, Fiberglass Reinforcement Mesh, Closed-Cell PVC Foam Layer, Wear Layer with PUR treatment |

| Total Thickness | 6.0 mm (± 0.2 mm) |

| Wear Layer Thickness | 1.5 mm (typical) |

| Surface Texture | Gem Surface (Optimized for Multi-Sport Traction) |

| Width per Roll | 1.8 m (standard) |

| Length per Roll | 20 m (standard) |

| Shock Absorption (EN 14904) | >30% (P1 Classification) |

| Vertical Deformation (EN 14904) | <3.5 mm |

| Coefficient of Friction (EN 13036-4) | 0.5 – 0.7 (Optimized for Pivoting & Traction) |

| Residual Indentation (EN 433) | <0.1 mm |

| Sound Absorption (ISO 717-2) | 18 dB (typical) |

| Fire Rating (EN 13501-1) | Bfl-s1 (Low smoke production) |

| Service Life Expectancy | 10-15 years under normal use |

The material composition leverages advanced PVC resins, selected for their superior elastic modulus and chemical stability. A key feature is the integration of a fiberglass reinforcement mesh, which provides exceptional dimensional stability, minimizing expansion and contraction under varying thermal conditions. The closed-cell PVC foam layer is critical for shock absorption, offering superior energy return and reducing impact-related injuries, aligning with P1 classification standards under EN 14904. The PUR-treated wear layer ensures superior abrasion resistance and ease of cleaning, extending the product's aesthetic and functional lifespan. These specifications underscore the product's suitability for demanding environments requiring optimal performance and safety, distinguishing it from conventional vinyl gym mat solutions.

Manufacturing Process Flow of Advanced PVC Sports Flooring

The production of high-performance PVC sports flooring, such as our multi-layer gem surface 6.0, involves a sophisticated, multi-stage manufacturing process designed to ensure material integrity, dimensional stability, and superior performance characteristics. This process integrates precision engineering with rigorous quality control at every step, distinguishing our products in the market for quality and longevity compared to standard vinyl gym mat offerings.

Key Stages of Production:

- Raw Material Preparation and Compounding: High-grade virgin PVC resins, plasticizers (e.g., DINP, DOTP for phthalate-free options), heat stabilizers, UV inhibitors, pigments, and fillers (e.g., calcium carbonate) are meticulously measured and mixed. This compounding process, often performed in high-speed blenders, ensures a homogeneous mixture critical for consistent material properties. The selection of materials adheres to international standards such as REACH for chemical safety.

- Calendering and Base Layer Formation: The compounded PVC mixture is fed into large calender machines. Through a series of heated rollers, the material is pressed and stretched into thin, uniform sheets, forming the base and intermediate layers. Precise temperature and pressure control during calendering are essential to achieve desired thickness and density, which impact the flooring's overall structural integrity.

- Fiberglass Reinforcement Lamination: A high-tensile fiberglass non-woven mesh is introduced and laminated between PVC layers. This critical step, often performed under controlled heat and pressure, imparts exceptional dimensional stability to the flooring, preventing curling, shrinking, and expansion due to temperature fluctuations. This is a key technical advantage over many basic flooring types.

- Closed-Cell Foam Layer Integration: A proprietary closed-cell PVC foam layer, engineered for optimal shock absorption and energy return, is thermally bonded to the upper PVC layers. The cell structure and density of this foam are precisely controlled during its formation to meet specific impact absorption criteria (e.g., EN 14904 P1 classification).

- Wear Layer and Surface Treatment: The top-most layer, the wear layer, is applied. This layer features the "gem surface" texture, created through specialized embossing rollers, which provides enhanced multi-directional traction and slip resistance. A final Polyurethane (PUR) surface treatment is then applied and cured, significantly improving abrasion resistance, stain resistance, and ease of maintenance, prolonging the service life.

- Curing, Cooling, and Trimming: The multi-layer material undergoes a controlled curing and cooling process to stabilize its structure. Subsequently, the material is precisely trimmed to standard roll widths (e.g., 1.8m) and inspected for any imperfections.

- Quality Assurance and Testing: Throughout and after production, each batch undergoes rigorous testing. This includes tests for thickness uniformity, dimensional stability (ISO 23999), wear resistance (EN 660-2), indentation (EN 433), slip resistance (DIN 51130 or EN 13893), shock absorption, and vertical deformation (EN 14904). Products are also tested for VOC emissions according to standards like AgBB/DIBt, ensuring compliance with indoor air quality requirements.

Target industries for this type of advanced flooring include professional sports arenas, educational institutions, fitness and wellness centers, and multi-purpose recreational facilities. The meticulous process ensures energy saving through optimized material use and reduced waste, and corrosion resistance for specific components is ensured through high-quality material selection. The service life, typically 10-15 years, is a testament to the robust manufacturing protocols and adherence to international testing standards (e.g., ISO 9001 for quality management, EN 14904 for sports surfaces).

Technical Advantages and Performance Metrics

The multi-layer PVC Sports Flooring with gem surface 6.0 offers a suite of technical advantages that position it as a premier solution for high-performance athletic environments. These advantages stem from its engineered composition and adherence to stringent performance benchmarks, surpassing many conventional vinyl gym mat products.

- Superior Shock Absorption (P1 Classification): With a shock absorption rate typically exceeding 30% (as per EN 14904), this flooring significantly reduces impact stress on athletes' joints and ligaments. This minimizes the risk of injuries and enhances comfort during extended periods of activity, directly contributing to athlete longevity and performance.

- Optimized Slip Resistance: The unique gem surface texture, combined with the PUR treatment, provides a consistent coefficient of friction (0.5 – 0.7) that is ideal for multi-sport activities. It allows for quick pivots and changes in direction without excessive grip or slippage, a critical safety feature in dynamic sports.

- Exceptional Durability and Wear Resistance: The robust wear layer and fiberglass reinforcement ensure a high resistance to abrasion, tearing, and heavy foot traffic. This extends the service life of the flooring, reducing lifecycle costs and maintenance frequencies compared to less robust alternatives.

- Dimensional Stability: The integrated fiberglass mesh provides unparalleled dimensional stability, preventing issues such as curling, gapping, or buckling, which can compromise both safety and aesthetics. This is crucial for maintaining a seamless playing surface over years of use.

- Acoustic Performance: The multi-layer structure, particularly the foam backing, offers significant sound absorption (up to 18 dB), contributing to a quieter and more focused athletic environment by reducing ambient noise and reverberation.

- Hygienic and Easy Maintenance: The non-porous PUR-treated surface is inherently resistant to bacteria, fungi, and common stains, making cleaning and sanitization straightforward. This is a vital advantage for facilities prioritizing hygiene and reducing operational expenditures.

- Environmental Compliance: Manufactured using phthalate-free plasticizers and adhering to low VOC emission standards, the flooring contributes to better indoor air quality, aligning with modern green building certifications.

These technical attributes collectively deliver a high return on investment for facility owners, ensuring a safe, high-performance, and cost-effective flooring solution that meets the rigorous demands of contemporary sports. The engineered superiority of this product clearly sets it apart from typical vinyl gym mat options.

Application Scenarios and Exemplary Case Studies

The versatility and robust performance characteristics of our multi-layer PVC Sports Flooring make it suitable for a diverse range of application scenarios across various sectors. Its engineering excellence caters to demanding environments where safety, performance, and longevity are paramount.

Typical Application Scenarios:

- Professional Sports Arenas & Training Centers: Ideal for basketball, volleyball, badminton, futsal, and handball courts where optimal ball bounce, consistent traction, and superior shock absorption are crucial for elite performance.

- Educational Institutions (Schools & Universities): Perfect for gymnasiums, multi-purpose halls, and fitness rooms, providing a safe and durable surface for students of all ages participating in various athletic activities.

- Community & Recreational Centers: Suited for public sports facilities that experience high foot traffic and require easy maintenance and a long-lasting surface.

- Fitness & Wellness Clubs: Excellent for group exercise studios, weight training areas (with appropriate underlayment), and general fitness zones, offering comfort and support for diverse workouts.

- Commercial & Hospitality (e.g., Hotel Gyms): Provides a high-end, durable solution for guest fitness areas, ensuring a professional and safe environment.

Application Case Studies:

Client: Major State University, Athletic Department

Challenge: The university's main gymnasium, built in the 1970s, featured an aging maple hardwood floor that required frequent, costly maintenance and offered insufficient shock absorption, leading to athlete complaints and increased injury rates. The department sought a modern, multi-sport surface that could withstand heavy use from collegiate athletics, intramural sports, and campus events.

Solution: Installation of 1,200 sq. meters of multi-layer PVC Sports Flooring with gem surface 6.0. The vibrant color scheme was customized to match university branding. The project included comprehensive subfloor preparation to ensure optimal adhesion and performance.

Results: Post-installation, the athletic department reported a 25% reduction in lower-extremity impact injuries among basketball and volleyball players. Athlete feedback consistently highlighted improved comfort and enhanced grip. The facility management noted a 60% decrease in annual maintenance costs compared to the previous hardwood floor, reinforcing the economic and performance advantages of the advanced vinyl gym mat.

Client: City of [Specific City], Parks & Recreation Department

Challenge: A heavily utilized community sports center required a robust and versatile flooring solution for its main hall, which hosted everything from children's sports leagues to senior fitness classes and public events. The existing concrete floor was hard, noisy, and posed slip hazards, limiting its utility.

Solution: Over 800 sq. meters of multi-layer PVC Sports Flooring with gem surface 6.0 were installed, providing a uniform, safe, and attractive surface. The design incorporated permanent court lines for basketball and volleyball, seamlessly integrated into the flooring.

Results: The new flooring transformed the space into a true multi-purpose facility. Anecdotal feedback from users praised the improved comfort and perceived safety. The center experienced an increase in bookings for sports programs and community events due to the enhanced facility. The department appreciated the flooring's durability and easy cleaning, crucial for a high-traffic public venue, validating the decision to invest in high-quality vinyl gym mat technology.

Vendor Comparison and Customized Solutions

When selecting performance flooring, B2B decision-makers face a critical choice among various materials and vendors. While different options exist, understanding the nuanced differences between types like vinyl gym mat, `vinyl floor tiles`, `vinyl floor carpet`, `wpc vinyl flooring`, and `vinyl spc flooring` is crucial for optimizing facility investment.

Flooring Solution Comparison Table:

| Feature/Type | Multi-Layer PVC Sports Flooring (e.g., Gem Surface 6.0) | Vinyl Floor Tiles (LVT/VCT) | WPC/SPC Vinyl Flooring | Vinyl Floor Carpet |

|---|---|---|---|---|

| Primary Application | Sports, Gyms, Multi-purpose Halls | Commercial, Retail, Office | Residential, Light Commercial | Office, Healthcare, Hospitality |

| Shock Absorption | Excellent (>30% P1) | Low to Moderate | Low (very rigid core) | Moderate (comfort layer) |

| Slip Resistance | Optimized (0.5-0.7 CoF) | Good (varies by surface) | Good | Excellent (tactile) |

| Dimensional Stability | Excellent (fiberglass reinforced) | Good | Superior (rigid core) | Varies (backing type) |

| Water Resistance | Excellent (seamless installation) | Good (seams can be vulnerable) | Excellent (waterproof core) | Poor (absorbent fiber) |

| Maintenance | Low (PUR treated, non-porous) | Moderate (requires waxing/sealing for VCT) | Low (easy to clean) | High (stains, vacuuming) |

While `vinyl floor tiles`, `wpc vinyl flooring`, and `vinyl spc flooring` offer excellent general-purpose durability and water resistance for commercial and residential settings, they typically lack the specialized multi-layer construction and foam backing required for sports performance. Their rigidity often results in lower shock absorption and less suitable friction coefficients for dynamic athletic movements. `Vinyl floor carpet`, despite offering acoustic benefits and underfoot comfort, is generally unsuitable for sports applications due to hygiene concerns, cleaning difficulties, and inadequate traction.

Customized Solutions: Tailored to Your Facility

We understand that every facility has unique requirements. Our commitment to customized solutions extends beyond standard product offerings:

- Color and Design Specificity: Offering a wide palette of colors and the ability to match specific branding guidelines, allowing facilities to create distinctive and cohesive interior aesthetics.

- Custom Court Markings: Permanent game line markings for various sports (basketball, volleyball, badminton, etc.) can be factory-applied or precisely installed on-site, ensuring accuracy and longevity.

- Thickness and Backing Optimization: While 6.0mm is standard for multi-sport, we can discuss variations in foam backing density or overall thickness for highly specialized applications requiring enhanced shock absorption or specific force reduction values.

- Installation Accessories: Providing all necessary welding rods, adhesives, and transition strips, often color-matched, to ensure a seamless and professional installation.

- Project Management Support: From initial consultation and specification development to installation guidance and after-sales support, our team offers end-to-end project management assistance to ensure successful implementation.

Our goal is to collaborate closely with clients to deliver a vinyl gym mat solution that precisely meets their operational, aesthetic, and budgetary objectives, ensuring optimal performance and maximum value for their investment.

Authoritativeness, Trustworthiness, and Client Support

Building trust and demonstrating authoritativeness are cornerstones of our B2B engagement. Our commitment to quality is underpinned by robust certifications, transparent client support, and clear commitments.

Certifications and Quality Assurance:

Our multi-layer PVC Sports Flooring products, including the gem surface 6.0, adhere to the highest international standards, ensuring reliability and performance:

- ISO 9001 Certified: Our manufacturing facilities and quality management systems are ISO 9001 certified, ensuring consistent product quality and process efficiency.

- EN 14904 Compliance: Our sports flooring meets or exceeds the requirements of EN 14904 for sports surfaces, specifically for shock absorption, vertical deformation, and sliding properties, crucial for athlete safety.

- CE Marking: Products bear the CE mark, signifying compliance with European health, safety, and environmental protection standards.

- Fire Safety Standards (EN 13501-1): Achieves Bfl-s1 rating, indicating low flammability and minimal smoke production, critical for public safety.

- REACH and Phthalate-Free: Our materials comply with REACH regulations and are manufactured with phthalate-free plasticizers, ensuring environmental responsibility and user health.

Warranty and Lead Time Commitments:

- Warranty: We provide a comprehensive 8-10 year limited warranty on our multi-layer PVC Sports Flooring, covering manufacturing defects and premature wear under normal use conditions. Specific terms are detailed in our product warranty statement. This commitment underscores our confidence in the durability of our vinyl gym mat.

- Lead Time: Standard lead times for production and delivery typically range from 3 to 6 weeks, depending on order volume, customization requirements, and destination. We maintain robust supply chain management to ensure timely fulfillment, and expedited options can be discussed for urgent projects.

After-Sales Support and Customer Service:

Our commitment to our clients extends far beyond the point of sale. We offer comprehensive after-sales support to ensure continued satisfaction and optimal performance of our flooring solutions:

- Technical Support: Our team of flooring specialists provides expert technical assistance for installation guidance, maintenance best practices, and troubleshooting.

- Maintenance Protocols: Detailed maintenance guides are provided with every order to help facilities preserve the longevity and appearance of their investment.

- Spare Parts & Repair: Availability of compatible repair kits and replacement sections to address any accidental damage efficiently.

- Dedicated Account Management: Each client is assigned a dedicated account manager for personalized service and seamless communication.

Frequently Asked Questions (FAQ):

A: Yes, the multi-layer construction provides excellent load-bearing capacity. For very heavy, stationary equipment (e.g., in weight rooms), additional subfloor reinforcement or specialized protective mats are recommended to prevent potential long-term indentation, even with a robust vinyl gym mat.

A: While wood offers unique aesthetics, our PVC sports flooring generally provides superior consistent shock absorption, better slip resistance in wet conditions, lower maintenance requirements, and greater dimensional stability, especially in environments with fluctuating humidity. It also significantly reduces noise.

A: Installation over existing, structurally sound, flat, dry, and clean subfloors (concrete, wood, ceramic tiles) is often possible after proper preparation. A thorough subfloor assessment by a qualified installer is always recommended to ensure optimal adhesion and long-term performance.

A: Our flooring is manufactured using environmentally responsible practices, is phthalate-free, and has low VOC emissions, contributing to healthy indoor air quality. It is also designed for long service life, reducing the frequency of replacement and associated waste.

Conclusion

The multi-layer PVC Sports Flooring with gem surface 6.0 represents the pinnacle of modern athletic surfacing, offering an unparalleled blend of technical superiority, safety features, and long-term value. Engineered with meticulous attention to detail and manufactured under stringent quality controls, this advanced vinyl gym mat solution is designed to meet the rigorous demands of professional sports, educational institutions, and community fitness centers.

By integrating superior shock absorption, optimized slip resistance, exceptional durability, and ease of maintenance, it provides a cost-effective and high-performance alternative to traditional flooring options. Our commitment to customized solutions, backed by robust certifications and comprehensive after-sales support, ensures that every investment in our flooring is a strategic decision towards enhancing athlete safety, performance, and facility longevity. Partner with us to elevate your athletic environments with a flooring solution built for excellence.

References

- European Standard EN 14904:2006. Surfaces for sports areas - Indoor surfaces for multi-sports use - Specification.

- International Organization for Standardization. ISO 9001:2015 - Quality management systems - Requirements.

- European Standard EN 13501-1:2007+A1:2009. Fire classification of construction products and building elements - Part 1: Classification using data from reaction to fire tests.

- The Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) Regulation (EC) No 1907/2006.

- ASTM F2772 – 11. Standard Specification for Athletic Performance Properties of Indoor Sports Floor Systems.

- ASTM F1912 – 13. Standard Test Method for Measuring the Minimum Coefficient of Friction for Wet High Traction Walking Surfaces.

-

Durable and Sustainable Polypropylene Interlocking Tiles for Modern Flooring

NewsNov.24,2025

-

Interlocking PP Tiles: Durable, Sustainable Flooring Solutions for Global Use

NewsNov.24,2025

-

The Complete Guide to Cost of Interlocking Tiles: Factors, Applications, and Vendors

NewsNov.24,2025

-

Outdoor basketball court SES Battle I - Durable, Anti-slip

NewsNov.24,2025

-

Multi Purpose Court Surface - Durable, Safe, Easy Install

NewsNov.24,2025

-

Durable Dumble Interlocking Tiles for Industrial Flooring

NewsNov.24,2025