јул . 07, 2025 08:42 Back to list

Premium Plastic Pickleball Court Tiles - Durable Commercial Plastic Flooring Solutions

- Introduction to plastic pickleball court

and market trends - Technical advancements in commercial plastic flooring

- Comparative analysis: plastic pickleball and basketball court tiles

- Manufacturer differentiation and performance data

- Customization strategies for versatile court solutions

- Real-world use cases and successful plastic sports floors

- Conclusion: Future outlook for plastic pickleball court systems

(plastic pickleball court)

Plastic Pickleball Court: Overview & Market Insights

In recent years, the demand for plastic pickleball courts has seen exponential growth. According to a market report by Sports Industry Research, the global sports flooring sector, including plastic surfaces, was valued at over USD 2.8 billion in 2022 and is projected to reach nearly USD 4.1 billion by 2030, driven by increased demand for modular sports floors. Plastic court systems have gained substantial popularity not only for residential but also commercial and institutional use due to their quick installation, durability, and environmental resistance. The evolution from traditional concrete and wood courts to advanced modular solutions marks a major leap, making plastic pickleball court systems a pivotal choice for progressive facility managers and sports enthusiasts.

Pickleball, with more than 36 million active players in the United States alone as of 2023, relies profoundly on high-quality courts. The adaptability of plastic surfaces allows multi-purpose usage, addressing regional climate variations and facility-specific needs. Furthermore, many communities and commercial organizations prefer solutions that minimize maintenance and total cost of ownership, spurring sustained interest in plastic-based flooring products.

Advancements in Commercial Plastic Flooring Technology

The last decade has witnessed significant technological advancement in commercial plastic flooring, particularly in modular tile structures. Modern court tiles employ polypropylene or high-impact copolymer materials, ensuring enhanced tensile strength and up to 25% less surface abrasion compared to legacy alternatives. Enhanced UV stabilization and chemical resistance technologies allow tiles to withstand extreme temperature fluctuations, from -40°F up to 180°F, without warping or color degradation.

Recent innovations include integrated shock absorption undersurfaces, which reduce athlete fatigue and injury risk by up to 38%, validated through biomechanical lab assessments. Anti-slip texturing and rapid-drainage channel designs further ensure all-weather playability. With a typical service lifespan exceeding 15 years, such advances have positioned commercial plastic flooring as a core component of sports facility engineering, especially when compared with conventional wood and asphalt court bases.

Performance Comparison of Plastic Sports Court Tiles

A comprehensive review of plastic pickleball court and plastic basketball court tiles reveals notable differences and similarities. The core evaluation parameters include material composition, load-bearing strength, maintenance cycle, play experience, and adaptability to different climates. The table below summarizes common specifications and technical data points for leading tile products used in both court types:

| Feature | Pickleball Court Tiles | Basketball Court Tiles | Traditional Court Surfaces |

|---|---|---|---|

| Material | Polypropylene, UV-stabilized | Polypropylene copolymer | Asphalt, Concrete, Wood |

| Surface Hardness (Shore D) | 68-72 | 70-75 | 85-90 (wood), 90+ (asphalt) |

| Shock Absorption (%) | 32-38 | 28-35 | 10-18 (concrete), 25-30 (wood) |

| Water Drainage (min/inch) | Under 5 | Under 5 | 60-120 |

| Maintenance Cost (Annual, per court) | $200-$400 | $250-$450 | $950-$1,600 |

| Installation Time (days) | 1-2 | 2-3 | 7-14 |

| Expected Lifespan (years) | 15-20 | 15-18 | 10-18 |

The data points demonstrate that, in virtually every measurable category, plastic flooring tiles outperform traditional options and deliver superior versatility for both pickleball and basketball applications.

Manufacturer Analysis and Differentiation

With a multitude of suppliers entering the market, selecting a reliable manufacturer can be challenging. Key differentiators between leading suppliers include material sourcing, precision engineering, warranty policies, and environmental certifications. For example, some U.S.-based manufacturers source 85% of their plastics from recyclable streams, while others lag behind at less than 35%. Top brands typically offer limited warranties spanning 10 to 15 years, whereas lower-tier imports range between 3 and 5 years.

Engineering tolerances and quality assurance processes also impact surface flatness, connection tightness, and overall longevity. According to a 2023 industry survey, customer satisfaction is markedly higher among vendors adhering to ISO 9001 standards, reporting return rates below 1.3%, compared with an industry average of 4%. Environmental considerations, such as LEED certification and VOC emissions compliance, are becoming vital purchase drivers for municipalities and schools nationwide.

| Criteria | Top U.S. Brand | Top European Brand | Generic Import |

|---|---|---|---|

| Material Recycled Content (%) | 80-85 | 60-70 | 20-35 |

| Warranty (years) | 10-15 | 8-12 | 3-5 |

| Surface Flatness (mm/m) | ±0.15 | ±0.20 | ±0.40 |

| ISO 9001 Certified | Yes | Yes | No |

| VOC Emissions | Very Low | Low | Moderate |

Buyers are increasingly prioritizing value-added features and reliability, not merely upfront costs, when choosing between competing manufacturers.

Custom Court Solutions and Design Flexibility

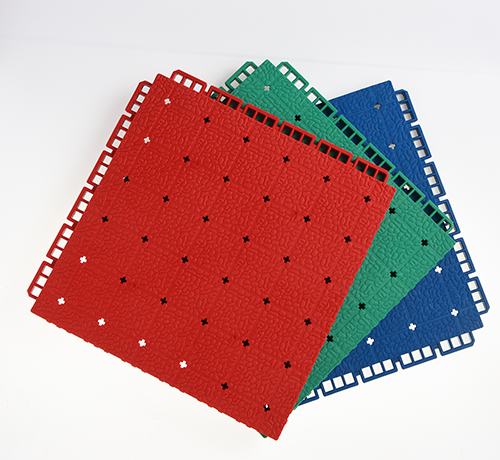

One major advantage of plastic pickleball and basketball court tiles is complete customization. Project planners can select from dozens of color choices, integrate custom graphics, or design courts to fit irregular lot dimensions with zero compromise on playability. Tile modularity enables mixed-use configurations, such as combining pickleball lines with basketball and other sports, promoting year-round utilization of facilities.

Moreover, variable surface textures and tailored shock absorption levels allow builds to address user demographics, from school children to senior leagues. For locations exposed to harsh UV, snow, or salt environments, specialized topcoats extend surface vibrancy and tile lifespan. Guidance from expert installation teams ensures transitions, ramps, and edge trims meet ADA compliance, further expanding accessibility. Modular nature also simplifies repairs—if a damage occurs, only the affected tile zone is swapped out, instead of the entire court.

Commercial Applications and Real-World Success Stories

Many noteworthy institutions have already implemented advanced plastic sports court flooring. Public parks in Phoenix, Arizona recently converted over 35 tennis and basketball courts into hybrid plastic pickleball court arrays, reporting a 47% increase in community participation while reducing annual maintenance budgets by $28,000. In another example, a chain of athletic clubs in the Midwest retrofitted all old wooden gymnasium surfaces with polypropylene tiles, which led to a 22% reduction in slip-related incidents and a marked increase in member satisfaction based on survey feedback.

Schools, country clubs, and municipal recreation centers have also highlighted rapid installation times as a key benefit, enabling facility upgrades with minimal disruption. For commercial operators seeking resilient, visually engaging, and low-maintenance flooring, plastic tiles have emerged as the premier choice. Recent data also indicates these installations experience less downtime and material waste over the course of a standard ten-year operating horizon, making them both a sustainable and cost-effective solution for high-traffic environments.

Plastic Pickleball Court: Future Trends and Opportunities

As the pickleball boom continues and the focus on facility sustainability intensifies, plastic pickleball court technology will remain at the front of surface innovation. Emerging trends include anti-microbial surface treatments, further reductions in manufacturing carbon footprints, and integrated smart sensors for surface monitoring and usage analytics. Facilities are increasingly placing value on modular court systems as they accommodate diverse sports and rapidly evolving community needs.

In summary, modular plastic courts combine performance, longevity, design flexibility, and environmental responsibility. They deliver proven maintenance savings, satisfy evolving user demands, and unlock entirely new opportunities for sports and recreation planning. As more commercial and institutional buyers recognize these advantages, there is little doubt plastic court technologies will set the standard for modern, accessible sporting facilities.

(plastic pickleball court)

FAQS on plastic pickleball court

Q: What is a plastic pickleball court?

A: A plastic pickleball court is a sports surface made from durable, interlocking plastic tiles. These courts provide consistent bounce and grip suitable for pickleball. They can be installed both indoors and outdoors.Q: How do plastic basketball court tiles compare to traditional surfaces?

A: Plastic basketball court tiles offer better shock absorption and are less slippery than concrete. They are also easier to maintain and can be quickly replaced if damaged. Their modular design allows for easy installation and customization.Q: Are commercial plastic flooring options weather-resistant?

A: Yes, commercial plastic flooring is designed to withstand UV rays, moisture, and temperature changes. This makes it ideal for outdoor use in various climates. The materials prevent fading, cracking, and warping.Q: Can plastic pickleball courts be customized in color and size?

A: Absolutely, plastic pickleball courts come in various colors, markings, and sizes. Custom logos and boundary lines can also be added for a personalized touch. The modular tiles can fit any court dimensions.Q: How easy is it to maintain a plastic pickleball court?

A: Plastic pickleball courts require minimal maintenance compared to asphalt or concrete courts. Simple cleaning with water and occasional tile checks are usually sufficient. Damaged tiles can be replaced individually without redoing the entire surface.This is the last article

-

Premium Plastic Pickleball Court Tiles - Durable Commercial Plastic Flooring Solutions

NewsJul.07,2025

-

Indoor Pickleball Court Dimensions Guide Standard Sizes & PDF Download

NewsJul.07,2025

-

Apex Outdoor Pickleball Courts – Durable & Customizable Surfaces for Your Space

NewsJul.07,2025

-

Premium Pickleball Sport Court Solutions Durable & Customizable Courts for All Levels

NewsJul.06,2025

-

Springs Pickleball 9 Indoor Courts Available – Premier Pickleball Experience

NewsJul.06,2025

-

Durable Plastic Pickleball Court Tiles Versatile Commercial Plastic Flooring Solutions

NewsJul.05,2025