Лип . 30, 2025 04:00 Back to list

Premium Maple Flooring for Gyms & Homes | PVC & Vinyl Options

In recent years, the flooring market has experienced seismic changes driven by innovation in materials, safety regulations, and a growing demand for sustainable products. Among the premium choices, maple flooring stands out as a classic for sports and high-performance environments, while engineered surfaces like pvc vinyl flooring, gym flooring, and advanced customizations for play areas are rapidly gaining traction.

This article provides a deep-dive into maple flooring — its manufacturing process, technical attributes, and comparative analysis with modern options such as ENLIO custom flooring for Kid's playground. We will examine application scenarios, key industry data, standards compliance, and showcase use cases to empower buyers, facility owners, engineers, and architects with trustworthy decision-making insights.

1. Industry Trends and Market Insights

- According to Allied Market Research, the global vinyl flooring market (including pvc vinyl flooring, buy vinyl flooring, and pvc flooring 2mm) is projected to reach $51.5 billion by 2027, with a CAGR of 5.1% (Source: Allied Market Research 2022).

- Increasing adoption in education, fitness, and leisure sectors due to enhanced safety, hygiene, and longevity requirements.

- Technological advancements (e.g., CNC machining, high-definition printing) have led to ultra-realistic wood patterns and improved durability in synthetic flooring.

- Global attention to standards such as ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and ANSI/ASTM F2772 (Sports Flooring Performance Standard) in procurement guidelines.

Key Parameter Comparison: Maple Flooring vs. PVC Vinyl Flooring vs. ENLIO Custom Playground Flooring

| Specification | Maple Flooring | PVC Vinyl Flooring | ENLIO Playground (PVC 2mm/4.5mm/6.0mm) |

|---|---|---|---|

| Raw Material | Hard Maple Wood | Polyvinyl Chloride (PVC) | PVC/Environment-friendly composite |

| Surface Hardness | Janka 1450 lbf | 60-100 Shore A | 65-80 Shore A |

| Wear Layer Thickness | 7-9 mm | 0.2-0.7 mm | 0.5-1.5 mm (custom) |

| Total Thickness | 20-38 mm | 2-4 mm (Standard PVC flooring 2mm/3mm) | 2.0/4.5/6.0 mm (custom) |

| Slip Resistance | R9-R10 | Up to R11 | Up to R11 |

| Shock Absorption | >50% (sports-grade) | 20-28% | 33%-48% (EN14904 Class 3-6) |

| Installation | Nail-down, Floating | Glue-down/Loose lay/Click | Interlocking/Glue/Loose lay |

| Maintenance | Refinishing required | Simple mopping | Low maintenance |

| Lifespan | 25–45 years | 8–15 years | 10–15+ years |

| Eco-standard | FSC, ISO 14001 | ISO 9001, FloorScore, Reach | EN/ISO 9001, EN14904, CE, SGS |

| Fire Resistance | Bfl-s1–Cfl-s1 | Bfl-s1 | Bfl-s1, EN 13501 |

| Cost (USD/sqm) | $40–$75 | $6–$18 | $15–$35 |

2. Maple Flooring Manufacturing Process: From Nature to Performance

The manufacturing of maple flooring is a sophisticated process that integrates advanced woodworking, precision engineering, and strict quality controls. Below is a process visualization using a logical diagram:

- Selection and Preparation: Only high-density hard maple (Acer saccharum) is chosen; logs are sawn to optimal grain direction for maximum stability.

- Kiln Drying: Precision controlled to maintain moisture content (<12%) as per ISO/ANSI specifications to prevent cupping and ensure durability.

- CNC Machining: Profile cutting—tongue & groove, micro-bevel—using advanced 5-axis CNC for exact dimensional tolerance (±0.1mm).

- Sanding & Finishing: Multi-stage sanding, UV-cured polyurethane or oil finish application, abrasion resistance testing (conforming to “Taber” standards).

- Quality Inspection: Each plank is tested according to EN 13629 and FIBA requirements for sports safety and wear life.

Notable technical attributes: Maple's close grain, Janka hardness (1450 lbf), high abrasion resistance, and natural shock-absorbing properties make it a gold standard for sports, gym flooring, and multisport areas.

Application Sectors: Professional sports venues, gymnasiums, school halls, multipurpose areas, commercial fitness centers, and artistic venues.

Advantages: Natural resilience, exquisite appearance, long service life (25+ years), eco-certifications (FSC, ISO 14001), consistent performance under variable humidity.

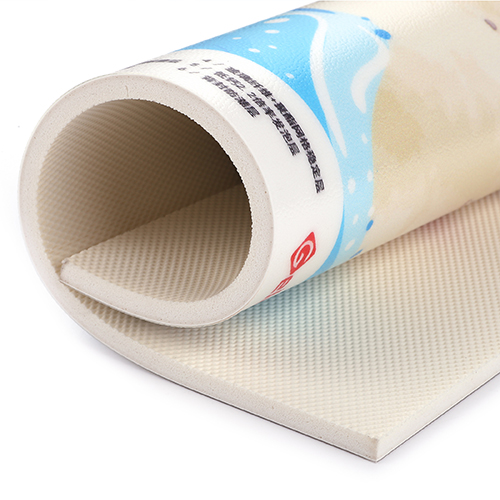

3. ENLIO Custom Flooring for Kid's Playground: Specification, Technology & Data Visualization

Product Overview

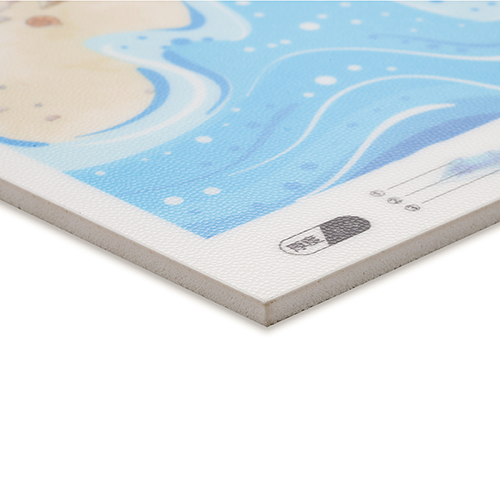

ENLIO custom flooring for Kid's playground is engineered for safety, durability, and creativity. Leveraging environmentally friendly PVC, multi-layer composite technology, and advanced surface treatments, ENLIO offers tailored solutions for indoor and outdoor playgrounds.

Key Technical Parameters

| Parameter | ENLIO Playground (Standard) | ENLIO Custom (Premium) |

|---|---|---|

| Total Thickness | 4.5 mm / 6.0 mm | 2.0 mm / Customized up to 8.0 mm |

| Wear Layer | 0.5 mm | 0.7–1.5 mm |

| Surface Design | Matte/Embossed | Custom Print/Patterned/High-Definition |

| Shock Absorption | ≥33% (EN14904 Class3) | 38–48% (EN14904 Class 4-5) |

| Slip Resistance (R) | ≥R10 | R11 (anti-skid) |

| Color/Design | 8 solid colors | Unlimited (customizable) |

| Width x Length | 1.8m x 15m (roll-form) | Custom cut |

| Fire Rating | Bfl-s1 (EN13501) | Bfl-s1/EN 13501 (highest safety) |

| Certifications | EN14904 / CE / SGS / ISO 9001 | EN14904 / REACH / TUV / SGS |

| Warranty | 8 Years | 10 Years |

Thickness Distribution of ENLIO Playground Installations (2023, %)

■ 4.5mm: Standard Playgrounds

■ 6mm: Premium Applications

Shock Absorption (EN14904 Classification)

ENLIO Customization Capabilities

- Wide range of thicknesses (2–8mm), suited for gym flooring, early childhood education, multifunctional and theme areas.

- Custom print options: games, alphabets, sports lines, logo embedding, high-res wood grain.

- EN14904 sports performance standard ensures safety, impact cushioning (anti-fall injuries), and consistent ballbounce (for sports applications).

- Surface antimicrobial & easy-to-clean treatment—suitable for high hygiene environments.

- Green manufacturing: ISO 9001, ISO 14001, CE, SGS certified; tested for VOC emissions (FloorScore/REACH compliant).

4. Manufacturer Comparison & Industry Certifications

| Brand | Main Market | Material System | Certifications | Service Years |

|---|---|---|---|---|

| ENLIO | Playgrounds, Sports, Gyms | PVC / Custom Heterogeneous | EN14904, ISO, CE, SGS, REACH | 14+ |

| Junckers | Sports, High-end Gyms, Commercial | Canadian Maple, Oak, Beech | FIBA, FSC, ISO | 85+ |

| Tarkett | Education, Sports, Healthcare | Vinyl, Linoleum, Hybrid | CE, ISO, FloorScore | 140+ |

| Gerflor | Multi-use, Gym, Play Area | PVC, Synthetic | EN, ISO, CE, REACH | 80+ |

- ENLIO delivers full-cycle project support: consultation, on-site measurement, design, rapid manufacturing, and install support globally.

- Long-term customer partnerships with educational groups, urban renewal projects, and international schools (over 28,000 cases worldwide).

- Annual third-party test by SGS/TUV ensures continued compliance and safety.

5. Application Scenarios & Typical Case Studies

- Educational Playgrounds: Kindergarten and elementary schools—colorful surface, 30%+ impact reduction, custom line graphics.

- Multi-sport spaces: Basketball, badminton, table tennis zones using both maple flooring and ENLIO vinyl composite for area zoning and performance balance.

- Indoor Play Centers: Theme-based centers benefit from fast-install interlock planks and vivid surface design.

- Commercial Gyms (gym flooring): ENLIO PVC 4.5/6mm offers durability, slip resistance, easy maintenance.

Case Study: Happy Star International Kindergarten, Malaysia

- Requirements: Safe, hypoallergenic surface, fast installation, custom hopscotch and learning patterns.

- Solution: ENLIO 4.5mm playground flooring; anti-slip R11, EN14904 certified, bespoke cartoon design integration.

- Outcome: Injury reduction >32%, teacher maintenance workload halved; praised for vibrant color persistence after 18 months (>95% colorfastness).

Case Study: City Fitness Chain, China

- Requirements: High foot-traffic resistance, quick floor replacement, affordable gym flooring.

- Solution: ENLIO PVC 6mm interlock tiles; meets EU fire rating (Bfl-s1), 46% shock absorption, 18 color choices.

- Outcome: Customer injuries reduced, surface maintained after 1M+ step-count, cost saved ~40% vs. solid wood alternatives.

Feedback Excerpt: “We chose ENLIO playground flooring for our kindergarten in Warsaw. The shock absorption and creative design possibilities exceeded expectations! — Project Manager, Wisla School, Poland”

6. Professional FAQ: Flooring Industry Technical Terms

7. Delivery Timeframe, Warranty & Customer Support

- Delivery: Standard ENLIO playground flooring is produced and shipped within 7–15 business days (custom color/design: 12–25 days).

- Warranty: 8–10 years (see product page for details). Extended warranty/maintenance contracts available.

- Support: Lifetime technical support, international dealer service, and onsite consultation.

- Quality Assurance: Each batch tested according to EN14904, SGS, and ISO9001. Certificate of Conformity provided.

- After-Sales: sales@enliosport.com for inquiries, replacements, or customization assistance.

8. Conclusion & Authoritative References

Maple flooring has long been revered in sports and performance settings for its natural attributes and timeless appeal. Modern engineered products like ENLIO custom flooring for Kid's playground and advanced pvc vinyl flooring are now bridging the gap, providing customization, safety, and economic advantages for a variety of sectors.

With industry-leading certifications, case-proven performance, and customer-centric service, ENLIO and comparable manufacturers offer robust, flexible solutions meeting the demands of the next-generation facility and playground standards.

References:

Allied Market Research - Vinyl Flooring Market Analysis 2022

Maple Flooring Manufacturers Association (MFMA) - PUR Specification

ENLIO Kid's Playground Flooring Official Product Page

ASTM F2772 - Standard Specification for Athletic Performance Properties

FlooringForum.com - Commercial & Sports Flooring Discussions

Google Scholar: Sports Flooring and EN14904 Research

This is the last article

-

Premium Maple Flooring for Gyms & Homes | PVC & Vinyl Options

NewsJul.30,2025

-

Premium Outdoor Basketball Court Tiles for All Weather Use

NewsJul.30,2025

-

Durable Basketball Board Stand for Indoor & Outdoor Use

NewsJul.29,2025

-

Durable Pickleball Court Tiles for Outdoor Sport Courts

NewsJul.29,2025

-

Premium PVC Vinyl Flooring for Homes & Gyms – Eco & WPC Options

NewsJul.29,2025

-

Premium Maple Flooring Solutions for Homes & Gyms

NewsJul.28,2025